Precision SS Tube Bending: Advanced Techniques & Essential Tools

Bending stainless steel tubes without defects is a challenge. Mistakes are costly, leading to material waste and weak structural integrity. Mastering the right techniques and tools ensures perfect results.

Mastering precision stainless steel tube bending requires a systematic approach combining meticulous preparation, correct tool selection, and advanced CNC technology. This ensures minimal material deformation and meets the strict tolerances required by industries like aerospace, automotive, and medical device manufacturing, significantly reducing waste and improving structural integrity.

Achieving a perfect bend in a stainless steel tube is where engineering meets artistry. It’s a process we at MFY have refined over thousands of projects. It's not just about forcing metal into a new shape; it's about guiding it with precision to maintain its strength and function. In this article, I'll walk you through the critical steps, from initial checks to the advanced techniques that separate standard work from exceptional results. Let's dive in.

What are the initial preparations needed for precision SS tube bending?

Rushing into the bending process often causes expensive errors. Poor preparation leads directly to cracked tubes, surface marring, and wasted material. Proper material inspection and accurate calculations are the essential first steps.

Initial preparations for precision stainless steel tube bending involve three key stages: verifying the material grade and checking for defects, accurately calculating the bend radius and springback, and ensuring the tube is clean and properly lubricated to prevent friction and galling during the process.

Before a single tube enters one of our benders, it undergoes a rigorous preparation phase. This isn't just about procedure; it's about risk mitigation. I remember a case with a new client in the medical device sector where a hairline fracture, invisible to the naked eye, caused a batch of tubes to fail under pressure testing. That experience reinforced our belief that preparation is over half the battle.

Material Verification and Inspection

The first step is always to confirm you have the right material for the job. Different grades of stainless steel, like 304 or 316L, have distinct properties of ductility and work-hardening. You must ensure the tube's specifications match the project's requirements for strength and corrosion resistance. We meticulously inspect the entire surface for any scratches, dents, or imperfections that could become stress points and lead to cracking during the bend.

Critical Bending Calculations

Next comes the math. Two factors are critical: the Center Line Radius (CLR)[^1] and springback. The CLR defines the arc of the bend, and it must be achievable for the tube's diameter and wall thickness. Springback is the natural tendency of the steel to partially return to its original shape after the bending force is released. Accurately predicting and compensating for springback is essential for achieving the target angle. For our CNC machines, these calculations are programmed in, but the underlying principles must be understood by the operator to make fine adjustments.

Surface and Tool Preparation

Finally, the tube and tooling must be pristine. We thoroughly clean the tube to remove any oils or debris that could cause imperfections. We then select and apply the right lubricant. This is crucial for reducing friction between the tube and the dies, which prevents galling (a form of wear caused by adhesion between sliding surfaces) and ensures a smooth, clean bend.

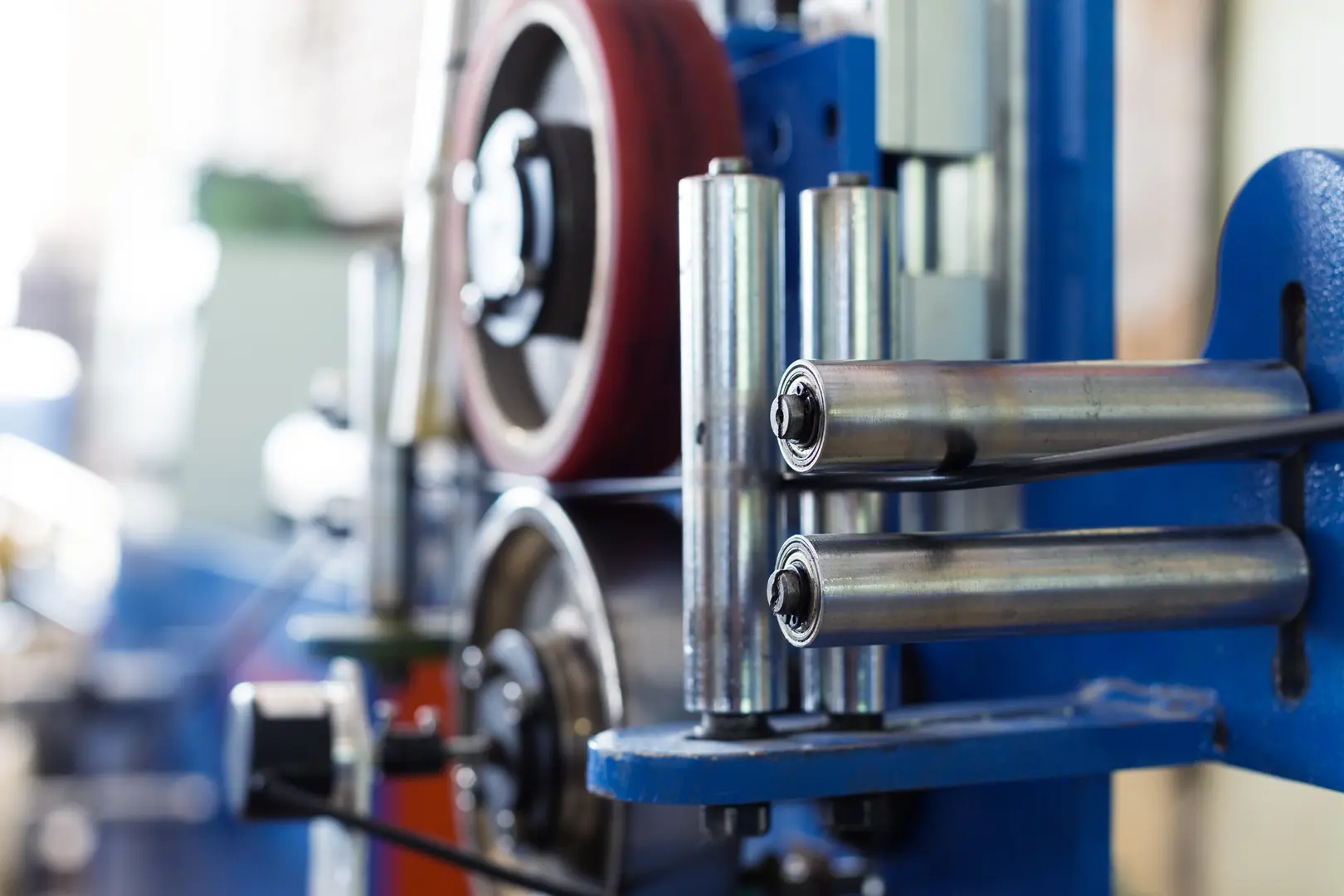

How do you select the right tools for SS tube bending?

Using the wrong tools is a guaranteed way to ruin your tube. This mistake not only damages expensive material but can also wear out or break your equipment. Choosing the right bender, mandrel[^2], and dies is absolutely critical for success.

Selecting the right tools involves matching them to the tube's outside diameter, wall thickness, and the desired bend radius. A rotary draw bender provides maximum control, while an internal mandrel is essential to prevent collapse, and a wiper die is needed to avoid wrinkles on tight-radius bends.

The tooling is where precision is born. Over the years, I've seen countless projects fail simply because the team tried to make do with a generic setup. For high-stakes industries like aerospace or automotive, "good enough" is never an option. The choice of tooling directly impacts the structural integrity and final quality of the component. A project for an automotive client producing high-performance exhaust systems taught us that the tiny investment in a perfectly matched wiper die saved them from scrapping thousands of dollars worth of thin-walled tubing that kept wrinkling.

The Bender: Manual vs. CNC

For simple, one-off jobs, a manual bender might suffice. However, for the precision, repeatability, and complex geometries demanded by modern industry, a Computer Numerical Control (CNC) bender is non-negotiable. CNC machines provide unparalleled control over the bending speed, angle, and pressure, allowing for the creation of intricate parts with minimal deviation, batch after batch. This technology is a cornerstone of our operations at MFY.

The Core Tooling Set

The bender itself is just one part of the equation. The tooling set that engages with the tube is just as important. Here’s a breakdown of the key components:

| Tool | Function | When It's Essential |

|---|---|---|

| Mandrel | An internal support that fits inside the tube. | Always for thin-walled tubes or tight-radius bends to prevent flattening and collapse. |

| Wiper Die | Sits in the concave part of the bend. | For tight-radius bends (CLR less than 3x the tube diameter) to prevent wrinkles. |

| Bend Die | A round die that determines the radius of the bend. | The core component of any bending operation. |

| Clamp Die | Grips the straight section of the tube to hold it in place. | Essential for securing the tube against the bend die. |

| Pressure Die | Supports the tube on the outside of the bend as it's drawn. | Provides counter-pressure to ensure a smooth, consistent bend. |

Choosing the right combination of these tools is what allows us to bend even challenging materials with precision, ensuring the final product meets the most stringent specifications.

What is the step-by-step process for achieving precision in SS tube bending?

Having a defined process can feel restrictive. However, skipping a single step in the bending sequence can lead to immediate failure and wasted effort. A systematic, repeatable approach ensures consistent, high-quality bends every time you work.

The process involves securely clamping the tube in the bender, positioning the mandrel correctly, applying steady and controlled pressure through the bend cycle, over-bending slightly to compensate for springback, and performing a final quality check to verify the angle and integrity of the finished part.

A well-defined process is the backbone of any scalable manufacturing operation. It removes guesswork and ensures that the quality we deliver from our facilities in China is the same high standard a client would expect anywhere in the world. Our operators follow a precise checklist for every single job, which is crucial for maintaining the tight tolerances required for components used in everything from medical equipment to architectural structures. This methodical approach is how we build trust and deliver reliability.

Step 1: Setup and Calibration

The process begins with loading the correct program into the CNC bender. The operator then installs the tooling set—the bend die, clamp die, pressure die, and wiper die. The most critical part of this step is setting the mandrel position. It must be placed precisely at the tangent point where the bend starts to prevent ovality without causing friction marks. The machine is calibrated to ensure all movements are exact.

Step 2: The Bending Cycle

Once the tube is loaded and clamped, the automated cycle begins. The clamp die secures the tube to the bend die. The bend die then rotates, drawing the tube with it. Simultaneously, the pressure die moves forward with the tube, applying consistent support. The mandrel remains stationary inside, preventing the tube from collapsing. The entire motion is smooth and controlled, at a speed optimized for the specific material and wall thickness to prevent cracking or excessive stress.

Step 3: Springback Compensation and Release

The CNC program automatically bends the tube slightly past the target angle. This "over-bending" is calculated to compensate for the material's springback. After the rotation is complete, the pressure is released, the clamp die opens, and the mandrel is retracted. The tube has now sprung back to the precise, desired angle.

Step 4: Post-Bend Inspection

The final step is a thorough quality check. We use digital protractors and calipers to verify the bend angle and check for any change in the tube's diameter (ovality). For mission-critical parts, we may use Coordinate Measuring Machines (CMM) to ensure every dimension is within the specified tolerance. Only after passing this inspection is the part considered complete.

How can you troubleshoot common issues during SS tube bending?

Bending stainless steel often creates frustrating defects. Wrinkles, cracks, and flattening are common problems that can ruin parts and destroy profitability. Knowing the root cause of each issue makes troubleshooting straightforward and effective.

To fix common bending issues, address wrinkles with a properly set wiper die, prevent flattening with a correctly sized mandrel, and stop cracking by reducing bend speed or checking material ductility. Proper lubrication and tool setup are the best preventative measures against most defects.

Troubleshooting is a daily reality in manufacturing. I believe the best operators are not those who never face a problem, but those who can diagnose and solve it quickly. At MFY, we train our teams to think like detectives. Instead of just scrapping a bad part, they analyze it to understand the "why." This continuous feedback loop helps us refine our processes and prevent the same issue from happening again, saving time and resources for our clients.

A Guide to Common Flaws and Fixes

Most bending problems can be traced back to an issue with tooling, setup, or the material itself. Here is a simple table we use internally to quickly diagnose and address the most frequent defects:

| Defect | Likely Cause(s) | How to Fix It |

|---|---|---|

| Wrinkling on Inside Radius | Insufficient support; wiper die is missing, worn, or set incorrectly. | Use a wiper die and ensure it is sharp and positioned tightly against the tube at the tangent point. |

| Flattening/Ovality in Bend | No mandrel used; mandrel is too small or not positioned far enough forward. | Use a correctly sized mandrel. Adjust its position forward until the flattening is eliminated. |

| Cracking on Outside Radius | Bending too fast; material lacks ductility; bend radius is too tight for the material. | Reduce the bend speed. Verify material specifications. If necessary, increase the bend radius. |

| Galling or Scratches | Inadequate lubrication; worn or damaged tooling; dirt on the tube or tools. | Apply a high-quality bending lubricant. Inspect all tooling for wear and replace if necessary. Clean all components. |

By understanding these relationships, an operator can move from simply identifying a flaw to implementing a targeted solution. This turns a potential setback into an opportunity to improve the process, ensuring higher quality and less waste on future runs.

What advanced techniques can enhance precision in SS tube bending?

Standard bending methods are not always enough for today's complex parts. Meeting modern design demands for lightweight and intricate components requires next-level skill and technology. Advanced techniques like multi-stack bending and simulation deliver superior results.

Advanced techniques include using CNC multi-stack benders for variable-radius bends in a single setup, applying boost bending to reduce wall thinning on tight radii, and employing simulation software to predict and correct issues like springback before any material is used.

Staying competitive in the global materials industry means embracing innovation. At MFY, our vision is to lead, and that requires investing in the technology that will shape the future of manufacturing. The keyInsights driving our strategy are clear: product designs are becoming more complex, and the demand for lightweight, high-strength components is rising. Advanced bending techniques are not just a "nice to have"; they are essential for meeting the evolving needs of our clients in high-tech sectors and for enabling the rapid prototyping that modern supply chains demand.

CNC Multi-Stack and Variable-Radius Bending

Some of the most advanced CNC benders feature "multi-stack" tooling. This allows the machine to have multiple die sets (for different radii) stacked on top of each other. The machine can switch between them automatically during a single cycle. This is a game-changer for producing complex parts, like automotive exhaust headers or aerospace fuel lines, that require multiple bend radii on a single tube. It eliminates the need for multiple setups, drastically reducing production time and improving accuracy.

The Power of Simulation Software

Before we bend a single piece of steel for a complex new part, we bend it a thousand times digitally. Modern simulation software allows us to create a virtual model of the entire bending process. We can input the tube material, dimensions, and tooling information, and the software will predict exactly how the metal will behave. It shows us where thinning, wrinkling, or excessive springback will occur. This allows us to adjust the process parameters and optimize the tooling design до manufacturing begins, saving immense amounts of time and material.

Boost Bending for Critical Applications

For applications with very tight radii on thin-walled tubes, a technique called boost bending is used. In this process, a booster applies axial pressure to the end of the tube, essentially pushing it through the bend. This helps reduce the tension on the outer wall of the bend, minimizing wall thinning and preventing fractures. It's a critical technique for producing high-performance, lightweight components where every gram and micron of material matters.

Заключение

Mastering precision stainless steel tube bending requires a blend of careful preparation, the right tooling, and advanced CNC technology. This disciplined approach minimizes waste, ensures structural integrity, and successfully meets the demanding specifications of today’s most innovative and fast-paced global industries.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.