Stainless Steel Finish Designations & Specs: ASTM Standards & Supply Range

Choosing the right stainless steel finish is complex. A wrong choice can lead to project failure and budget overruns. Understanding ASTM standards is the key to making the right decision.

Stainless steel finish designations are standardized codes, primarily defined by ASTM A480/A480M, that specify a surface's texture, roughness, and reflectivity. These standards provide a universal language for quality, while the market supply ranges from common mill finishes to highly specialized, polished surfaces.

As someone who navigates the global stainless steel market daily, I see firsthand how a simple finish designation can make or break a project. It’s not just about aesthetics; it's about performance, durability, and cost-effectiveness. The gap between a specification on paper and the physical product delivered can be vast. That’s why my team at MFY and I believe that demystifying these standards is fundamental. Let's dive into what these designations mean, what the market can realistically supply, and how you can ensure you get exactly what you need.

Why are ASTM Standards Crucial for Stainless Steel Finish Designations?

Inconsistent finishes create quality issues. This uncertainty can erode trust between suppliers and buyers, causing costly disputes. ASTM standards provide a common language, ensuring everyone agrees on what "quality" means.

ASTM standards, particularly A480/A480M, are crucial because they establish a universal technical framework. This framework defines, measures, and verifies stainless steel surface finishes, ensuring consistency and predictable performance for manufacturers and end-users across the global supply chain.

At its core, the challenge in our industry is communication. A client in Germany needs to know that the "No. 4 finish" they order will be identical to the one they received last year, and identical to the one their competitor in Japan is using. Without a shared set of rules, this is impossible. This is where the American Society for Testing and Materials (ASTM) provides immense value.

The Role of ASTM A480/A480M

The key document here is ASTM A480/A480M, which is the standard specification for flat-rolled stainless and heat-resisting steel plate, sheet, and strip. It's the bedrock that defines the most common finishes we use every day. It acts as a universal language, bridging the gap between our production mills and the diverse industrial requirements of our clients. It ensures that when we at MFY supply a No. 2B finish, it meets a globally recognized standard for smoothness and reflectivity.

A Common Ground for Quality

I remember a project with an architectural firm in Dubai that required thousands of panels with a uniform brushed finish. The slightest variation would be visible on the building's facade. By anchoring our entire production and quality control process to the ASTM No. 4 finish specification, we eliminated ambiguity. We weren't just selling steel; we were selling a guarantee of consistency, backed by a global standard. This is how standards transform a simple commodity transaction into a trust-based partnership.

| ASTM Finish | Описание | Common Application |

|---|---|---|

| No. 1 | Hot-rolled, annealed, and descaled. Rough, dull. | Industrial applications, air heaters, furnace parts. |

| No. 2B | Cold-rolled, annealed, pickled, passivated. Smooth, reflective. | The "workhorse" finish. Food equipment, plumbing. |

| No. 4 | General purpose polished finish. Brushed look. | Kitchen equipment, architectural panels, dairy. |

| No. 8 | Highly reflective, mirror-like finish. | Decorative trim, reflectors, ornamental purposes. |

What is the Current Supply Range of Stainless Steel Finishes in the Market?

You need a specific finish for your project. But you're unsure what's readily available or if your design is even feasible. The market today offers a vast range, from standard mill finishes to highly customized surfaces.

The current market supply ranges from common, cost-effective mill finishes like No. 1 and No. 2B, to mechanically altered surfaces like the popular No. 4 brushed finish and the highly reflective No. 8 mirror finish, meeting diverse functional and aesthetic demands.

Understanding the available palette of finishes is the first step in effective design and procurement. The good news is that the industry has evolved far beyond a few basic options. At MFY, our integrated supply chain gives us a bird's-eye view of what is possible and what is practical on a global scale. We categorize the supply range into a few key groups.

Mill Finishes: The Foundation

These are the most cost-effective finishes, produced directly at the steel mill. The most common is No. 2B, a smooth, moderately reflective finish that serves as the starting point for many other polished finishes. It's the workhorse of the industry, used in everything from chemical processing tanks to home appliances. No. 1 finish is rougher and used where appearance is not a primary concern but heat resistance is.

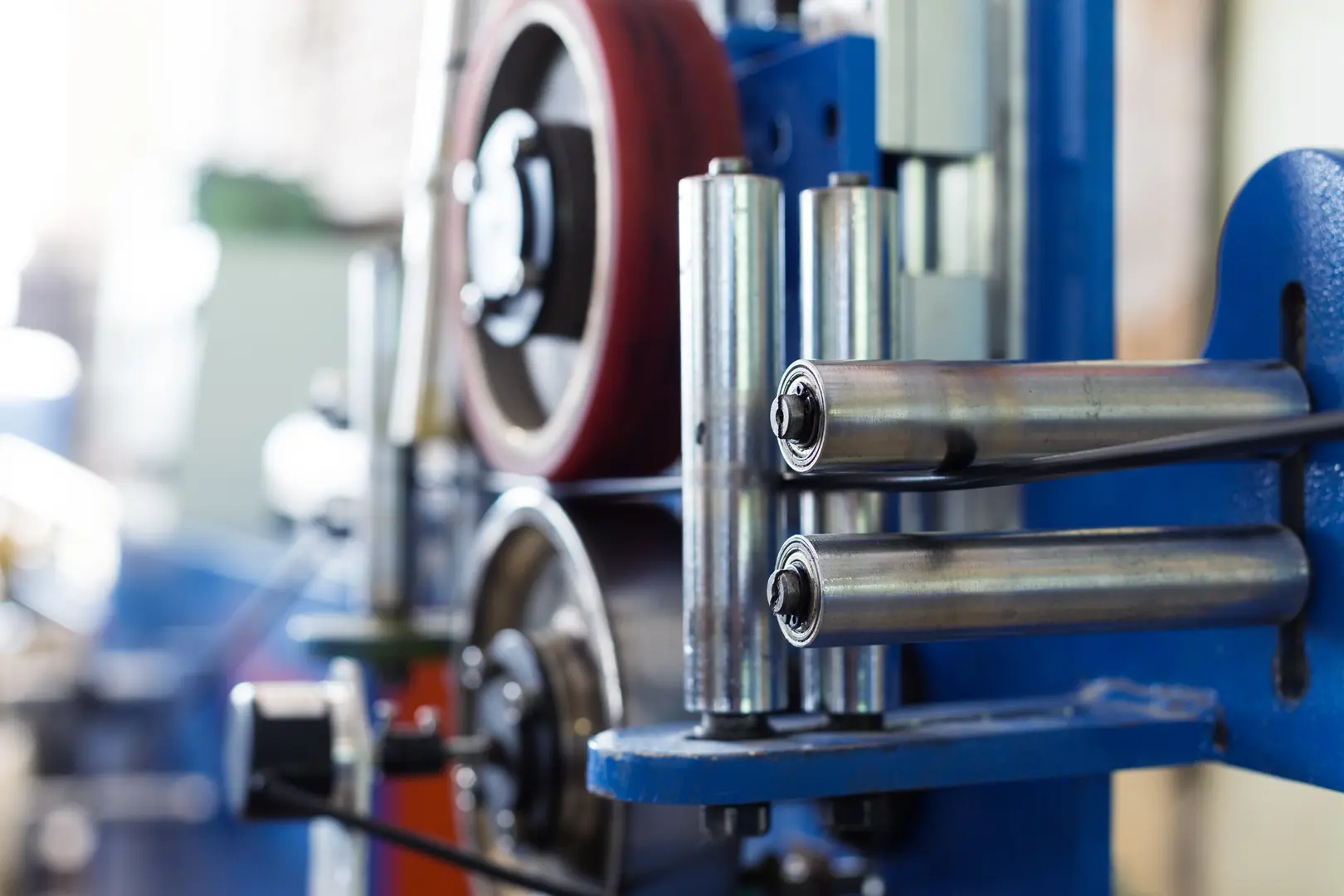

Mechanically Polished Finishes: The Next Level

This is where aesthetics and function begin to merge. The No. 4 "brushed" finish is perhaps the most recognizable, found on everything from kitchen sinks to elevator doors. It's created by polishing the steel with progressively finer abrasives. For the ultimate in reflectivity, the No. 8 "mirror" finish is so highly polished that it's difficult to distinguish from an actual mirror. Achieving this requires incredible skill and precise machinery.

I recall a client in the medical device industry who needed a finish smoother than standard No. 2B for hygienic reasons but didn't need a full No. 8 mirror. We worked with them to develop a custom polished finish that met their exact surface roughness (Ra)[^1] value, demonstrating how a flexible supply chain can move beyond standard offerings to provide tailored solutions. That's the agility we pride ourselves on at MFY.

What are the Main Challenges in Meeting ASTM Specifications for Stainless Steel Finishes?

Meeting specifications seems straightforward on paper. But in reality, inconsistencies can derail entire projects and budgets. Understanding the production challenges is the first step to mitigating risk and ensuring quality.

The main challenges include maintaining consistent surface roughness (Ra) across large batches, preventing surface contamination during handling and processing, and accurately measuring highly reflective finishes. Sourcing raw material of consistent quality is another significant hurdle for many suppliers.

Delivering on the promise of a specific ASTM finish is where the real work begins. It's a process fraught with technical difficulties that separate the best suppliers from the rest. At MFY, our vertical integration[^2] gives us a unique advantage in controlling these variables, but the challenges are universal and every buyer should be aware of them.

The Consistency Conundrum

For finishes like No. 4, the "brushed" look is created by abrasive belts. These belts wear down. Maintaining the exact same line depth and pattern across thousands of square meters of steel requires constant calibration and expert oversight. A slight variation can result in a "patchwork" effect when panels are installed side-by-side. I've seen this happen on major architectural projects, and it's a costly mistake to fix.

The Measurement Maze

How do you measure a mirror? For a No. 8 finish, visual inspection is not enough. We have to use instruments like gloss meters and profilometers to provide quantitative data that proves the surface meets the client's—and the standard's—requirements. This requires a significant investment in quality control equipment and training. We once had a client in the semiconductor industry who needed a specific Ra value for their cleanroom equipment. Our ability to not only produce the finish but also provide certified metrology reports was the deciding factor in winning their business.

Contamination and Handling

The moment a sheet comes off the polishing line, it's vulnerable. A single fingerprint, a spec of dust, or a minor scratch can ruin a perfect No. 8 mirror finish. This is why our handling, packaging, and logistics processes are just as critical as the production itself. We use specialized protective films and careful crating to ensure the finish that leaves our facility is the same one that arrives at the client's site.

How Can You Overcome Supply Chain Limitations for Stainless Steel Finishes?

Supply chain delays and inconsistencies can halt your production. This costs you valuable time and money. A strategic partnership with a fully integrated supplier is the most effective solution to this problem.

Overcome limitations by partnering with a vertically integrated supplier like MFY. This ensures end-to-end quality control, from raw material to final product. It also allows for diversified sourcing to mitigate risk and strategic inventory management to guarantee rapid delivery.

In today's volatile global market, a resilient supply chain is not a luxury; it's a necessity. For a product as specific as a finished stainless steel sheet, the risks are even higher. A breakdown at any point—from the raw material melt to the final polishing—can cause significant disruptions. This is why we built MFY's business model around the concept of vertical integration.

The Power of Vertical Integration

Because we are deeply involved from the raw material stage all the way through to global logistics, we have unparalleled control over quality and availability. We aren't just a trading company hoping our suppliers meet the standards; we are an active part of the process. This allows us to catch potential issues early and pivot quickly. If a specific batch of raw material doesn't have the right characteristics for a perfect No. 8 finish, we know it before it ever enters the polishing line, saving time and resources.

Strategic Inventory and Logistics

We analyze market trends and client needs to maintain a strategic inventory of the most commonly requested stainless steel grades and finishes. For a large construction contractor in Southeast Asia, we were able to air-freight a specific quantity of No. 4 finished sheets within 72 hours because we had it in stock, saving their project from a costly delay when their local supplier failed. This is the kind of agility that a fragmented supply chain simply cannot offer. It transforms the supplier relationship from a simple transaction into a strategic advantage for our clients.

What are the Key Technical Recommendations for Selecting the Right Stainless Steel Finish?

Choosing a finish is a critical project decision. The wrong choice can compromise performance, increase maintenance costs, and ruin aesthetics. Consider these key technical factors before you make your final selection.

Always evaluate the application's service environment for corrosion risk, the required aesthetic, and future fabrication needs like welding or forming. Matching the finish's surface roughness and cleanability to its functional requirements is the most critical step.

As a final piece of advice, I want to share the framework we use at MFY to guide our clients toward the best possible choice. Selecting a finish is a balancing act between performance, aesthetics, and budget. Asking the right questions upfront can save you from significant headaches down the road.

Environment and Corrosion Resistance

This is the most important factor. Is the stainless steel going to be in a coastal area with salt spray? Or in a sterile food processing facility? Smoother, non-porous finishes like No. 2B or a polished finish are easier to clean and offer fewer microscopic crevices where chlorides or bacteria can hide. For highly corrosive environments, a smoother finish is always a better choice than a rough or heavily textured one.

Fabrication and Maintenance

How will the material be used? If it needs to be welded, a highly reflective finish like No. 8 will show heat tint and discoloration more prominently than a dull or brushed finish. If it's in a high-traffic public area, a No. 4 brushed finish is excellent at hiding minor scratches and fingerprints, significantly reducing maintenance costs compared to a mirror finish.

A Practical Selection Guide

To simplify the process, here is a quick reference table we often share with our partners.

| Приложение | Ключевое соображение | Recommended ASTM Finish |

|---|---|---|

| Architectural Cladding | Aesthetics, weather resistance | No. 4, No. 6, Custom |

| Food & Beverage Tanks | Hygiene, cleanability, corrosion | No. 2B, No. 4 |

| Medical Devices | Sterility, smoothness | No. 2B, Electropolished |

| Elevators & Appliances | Durability, fingerprint resistance | No. 4, Vibration, Bead Blasted |

| Decorative Trim | High reflectivity, appearance | No. 8 (Mirror) |

Заключение

Understanding ASTM standards for stainless steel finishes is not just about technical compliance. It's a strategic tool for ensuring quality, reducing risk, and achieving project success. Partnering with an expert, integrated supplier like MFY makes this complex process simple and reliable.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.