Precision Bending Die Selection: Mandrel & Wiper Die Technical Guide

Bending defects ruin projects and inflate budgets. Costs rise, deadlines slip, and quality suffers. Master your die selection process to ensure flawless results and protect your bottom line.

Mastering precision bending die selection involves a technical approach to choosing the right mandrel and wiper dies. This requires understanding material properties, bend radius, and wall thickness to prevent defects like wrinkling and ovality, ensuring a perfect bend every time.

In my years as Global Business Director at MFY, I've seen countless projects succeed or fail based on one critical factor: the quality of the tube bend. It’s not just about shaping a piece of metal; it’s about maintaining its structural integrity and dimensional accuracy. The secret isn't just in the machine, but in the tooling. Specifically, the mandrel and wiper dies. Getting this combination right is the difference between a high-value component and expensive scrap. Let's break down how to make the right choice, every time.

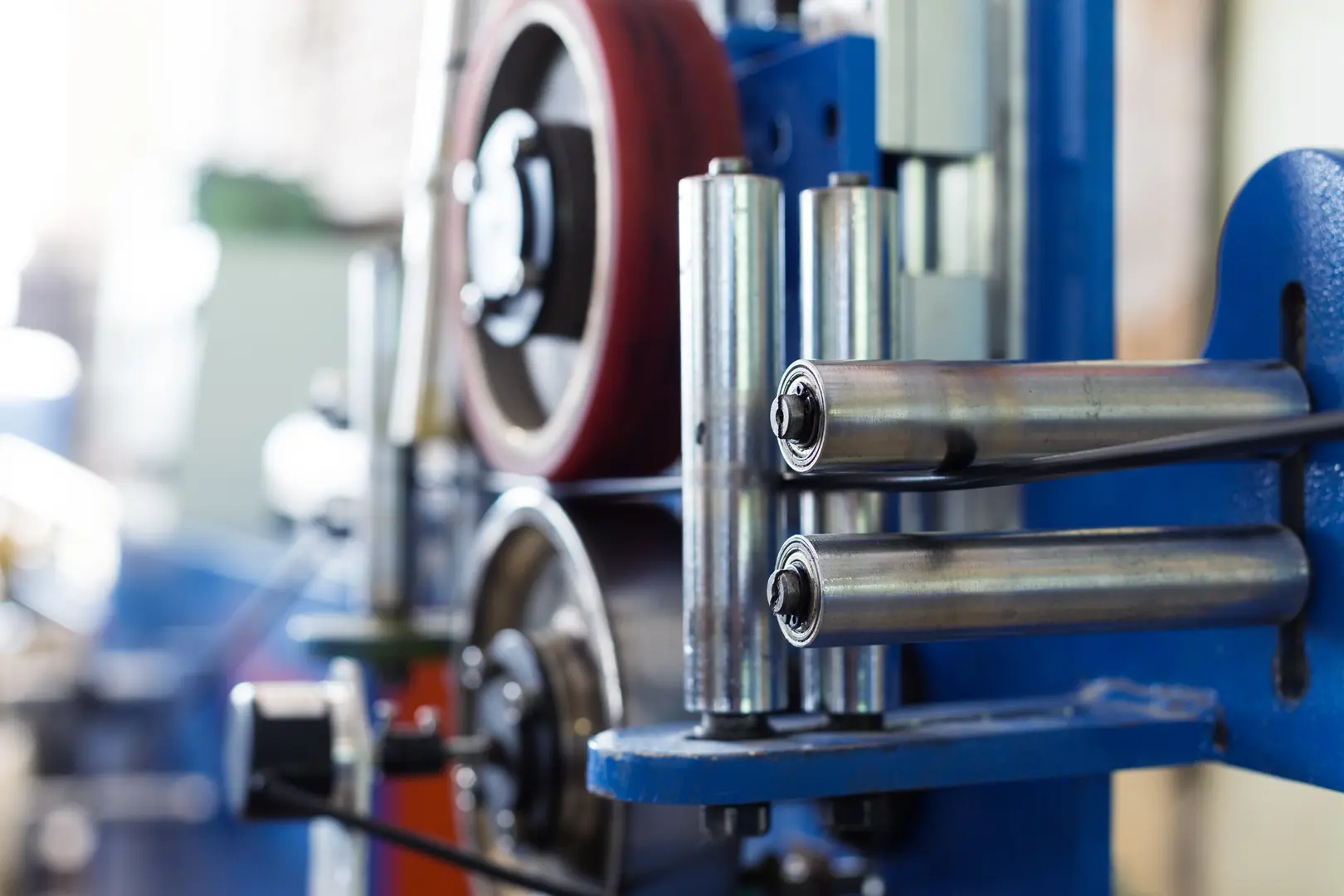

What Are the Basics of Mandrel and Wiper Dies?

Misunderstanding your tools leads to costly errors. You might be using the wrong die for the job without realizing it. Let's cover the fundamental roles they play in precision bending.

A mandrel die supports the tube's inner diameter during bending to prevent collapse or ovality. A wiper die is placed at the bend's tangent point to prevent wrinkles on the inside radius, ensuring a smooth, high-quality finish.

At their core, these two components work in tandem to control the flow of material as it's being formed. I remember a client in the aerospace sector who was struggling with inconsistent bends on thin-wall stainless steel tubing. They had a top-of-the-line bender, but their rejection rate was sky-high due to wrinkling. The problem wasn't their machine or their material; it was a fundamental mismatch in their tooling. They were using a standard mandrel on a job that required a thin-wall ball mandrel[^1], and their wiper die wasn't properly seated. This simple oversight was costing them thousands daily.

The Role of the Mandrel

The mandrel is your primary defense against tube collapse. As the tube is drawn around the bend die, the outer wall thins and stretches, while the inner wall compresses. Without internal support, the tube will naturally flatten or buckle. The mandrel's job is to provide that crucial internal support, maintaining the tube's original shape, or ovality, throughout the bend. The type of mandrel—from a simple plug to a multi-ball assembly—is chosen based on the difficulty of the bend.

The Function of the Wiper Die

The wiper die addresses the other side of the equation: compression. As the material on the inside of the bend is compressed, it has a tendency to form small wrinkles. The wiper die is positioned precisely at the point where the straight section of the tube begins to bend. Its sharp, feathered edge "wipes" the inside radius, smoothing the material and preventing these wrinkles from forming. It's a small part that plays a huge role in the final aesthetic and structural quality of the bend.

| Tool | Primary Function | Common Defects Prevented |

|---|---|---|

| Mandrel Die | Provides internal support to the tube | Ovality, collapse, buckling |

| Wiper Die | Smooths the inner radius of the bend | Wrinkling, compression marks |

How Do You Select the Right Mandrel Die?

Choosing the wrong mandrel causes tube collapse. When this happens, production halts, valuable material is wasted, and your project timeline is jeopardized. Follow a systematic selection process to avoid this.

Selecting the right mandrel die depends on the tube's wall factor (OD/wall thickness) and the "D" of bend (centerline radius/OD). Different mandrel types, like plug, standard, or ball mandrels, are chosen based on these calculations to provide appropriate internal support.

The selection of a mandrel is less of an art and more of a science. It's a calculated decision based on the specific properties of the tube and the geometry of the bend. At MFY, we work with clients across industries, from automotive to construction, and this calculation is the first thing we discuss when they need high-quality stainless steel tube for complex applications. Overlooking these simple ratios is the most common source of bending problems. It's about applying a technical framework to what seems like a simple task, which is how you achieve repeatable, high-quality results and maximize your production efficiency.

Calculating Key Ratios

Before you can choose a mandrel, you need two numbers. First is the Wall Factor, calculated by dividing the tube's outside diameter (OD) by its wall thickness. A higher wall factor indicates a thinner wall relative to its diameter, making it more prone to collapse. Second is the "D" of Bend, calculated by dividing the bend's centerline radius (CLR) by the tube's OD. A smaller "D" of bend indicates a tighter, more difficult bend. These two metrics give you a clear picture of the application's difficulty.

Matching Mandrel Type to Application

With your ratios calculated, you can select the appropriate mandrel. The goal is to provide enough support without creating excessive friction or drag. For simple, thick-walled bends, a basic plug mandrel might suffice. As the bend becomes more challenging (higher wall factor, smaller "D" of bend), you need more articulated support.

| Mandrel Type | Typical Application | Bend Difficulty |

|---|---|---|

| Plug Mandrel | Thick-wall tubes, large radius bends | Low |

| Standard Mandrel (1-2 Balls) | General purpose, moderate bends | Medium |

| Thin-Wall Mandrel (3-4 Balls) | Thin-wall tubes, tight radius bends | High |

| Ultra-Thin-Wall (5+ Balls) | Very thin walls, very tight radii | Very High |

How Do You Choose the Appropriate Wiper Die?

Wrinkles are forming on the inside of your bends. This not only looks unprofessional but can also compromise the structural integrity and flow characteristics of the tube. Let's focus on proper wiper die selection.

Choose a wiper die based on the material being bent, the centerline radius of the bend, and tooling clearance. The wiper's material (e.g., steel, bronze) and tip thickness must be correct to prevent galling and effectively smooth out the inner radius.

The wiper die is often the most overlooked component in the tooling set, yet it's responsible for the final finish. A few years back, we had an automotive client producing stainless steel exhaust systems. They were getting flawless bends in terms of ovality but were plagued by fine wrinkles on the inside radius. They had tried everything—adjusting clamp pressure, changing lubricants—but nothing worked. The solution was simple: they were using a standard steel wiper die. We advised them to switch to an aluminum-bronze wiper, which has better lubricity when working with stainless steel. The galling stopped, the wrinkles disappeared, and their production line was back to full efficiency.

Material Considerations

The material of the wiper die is critical. You need to create a dissimilar metal interaction to prevent galling, which is a form of wear caused by adhesion between sliding surfaces. For bending stainless steel, aluminum-bronze wipers are often the best choice because they are less likely to stick to the tube material. For carbon steel or aluminum, a standard hardened steel wiper may be perfectly adequate. The key is to match the wiper material to the tube material to ensure a smooth, low-friction "wiping" action.

Proper Fit and Placement

A wiper die must be perfectly fitted to the tube and the bend die. It should have a groove that matches the tube's OD exactly. The tip of the wiper must be "raked" or angled slightly so that it makes contact with the tube at the exact tangent point of the bend. If it's too far forward, it will create drag; if it's too far back, it won't prevent wrinkles. The tip should also be as thin as possible without sacrificing strength, allowing it to fit tightly against the bend die and leave no room for material to buckle.

What Are the Best Tips for Integrating Mandrel and Wiper Dies?

You have the right dies, but the results are still poor. Your setup is likely incorrect, leading to wasted time and material as you try to diagnose the issue. Proper integration is the key to success.

For successful integration, ensure precise alignment and setup. The mandrel nose should be correctly positioned relative to the bend's tangent line, and the wiper die must have light, even contact. Proper lubrication is also absolutely critical to reduce friction and prevent tool wear.

Think of your tooling set as a team. If one member is out of position, the entire team fails. This is where operator skill and modern technology converge. We're seeing more clients adopt simulation software[^2] to model their bending process before a single piece of steel is touched. This allows them to perfect the setup in a virtual environment, defining the exact placement of the mandrel, the pressure of the wiper, and the optimal lubrication strategy[^3]. This is part of the strategic roadmap for modern manufacturing: using digital tools to de-risk the physical process, ensuring efficiency and quality from the very first bend.

The Critical Role of Lubrication

Never underestimate the power of a good lubricant. It's the lifeblood of the bending operation. A high-pressure lubricant reduces friction between the tube and all tooling components—the mandrel, the wiper die, and the bend die. This not only prevents galling and scratching but also reduces the force required to make the bend, which extends the life of both the machine and the tooling. The type of lubricant (e.g., paste, oil, synthetic gel) should be chosen based on the material and severity of the bend.

Achieving Perfect Alignment

Proper setup is non-negotiable. The relationship between all tooling components must be precise. The wiper die must be flush against the bend die, the pressure die must apply even force, and the mandrel must be in the correct forward position.

| Pre-Bend Setup Checklist | Status | Notes |

|---|---|---|

| Mandrel Position | Verified | Nose should be slightly forward of the tangent point. |

| Wiper Die Contact | Verified | Light, even contact along the tube. No gaps. |

| Pressure Die Force | Calibrated | Enough force to prevent slipping, but not to deform the tube. |

| Lubrication | Applied | Mandrel, tube ID, and wiper die are properly lubricated. |

| Tooling Cleanliness | Verified | All components are free of debris from previous bends. |

What Maintenance Practices Extend the Life of Your Dies?

Your tooling is wearing out far too quickly. This directly increases your operational costs and leads to unexpected downtime for replacements. Implement a simple, effective maintenance routine to fix this.

Extend die life through regular cleaning to remove metal debris and lubricant residue. Inspect for wear, cracks, or galling after each run. Store dies properly in a dry, protected environment to prevent corrosion and damage. Proper handling is also essential.

Your bending dies are an investment, and like any investment, they require care to provide a good return. A well-maintained set of tooling not only lasts longer but also produces more consistent, higher-quality parts. We encourage all our partners to think about tooling life not in terms of time, but in terms of the number of quality bends produced. A simple maintenance schedule is the single best way to maximize that number. It reduces long-term costs and, more importantly, ensures that your production remains predictable and reliable. This focus on cost-effectiveness and throughput is what separates the leaders in the industry.

Daily Inspection Checklist

At the end of every shift or production run, a quick inspection can prevent major problems down the line. Clean the tooling thoroughly to remove all lubricant and metal shavings. This allows for a clear visual inspection. Look for signs of galling (material buildup) on the wiper die and mandrel balls. Check for any chips or cracks, especially on the thin edge of the wiper die. Polishing out minor imperfections can prevent them from becoming major failures.

Long-Term Storage and Care

How you store your dies is just as important as how you use them. After cleaning, apply a light coat of a rust-preventative oil[^4]. Store them in a designated, dry area where they won't be knocked around or damaged. Avoid stacking dies directly on top of each other, as this can damage the precision-machined surfaces.

| Maintenance Schedule | Tasks |

|---|---|

| Daily | Clean all tooling. Inspect for galling, chips, or cracks. Polish minor imperfections. |

| Weekly | Re-verify critical dimensions and fit. Check for signs of abnormal wear. |

| Monthly/As Needed | Send for professional repolishing or re-coating if wear becomes significant. |

Conclusion

Mastering die selection is a technical skill, not guesswork. It requires a clear understanding of the relationship between your material, your tooling, and your setup. This knowledge is the key to achieving the quality, efficiency, and profitability essential for success in any precision bending operation.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.