Understanding #4 Finish Stainless Steel: Technical Specs and Bulk Stock Availability

Struggling to source #4 finish stainless steel consistently? Market volatility creates project delays and budget overruns. A deeper understanding of its specs and supply chain is your solution.

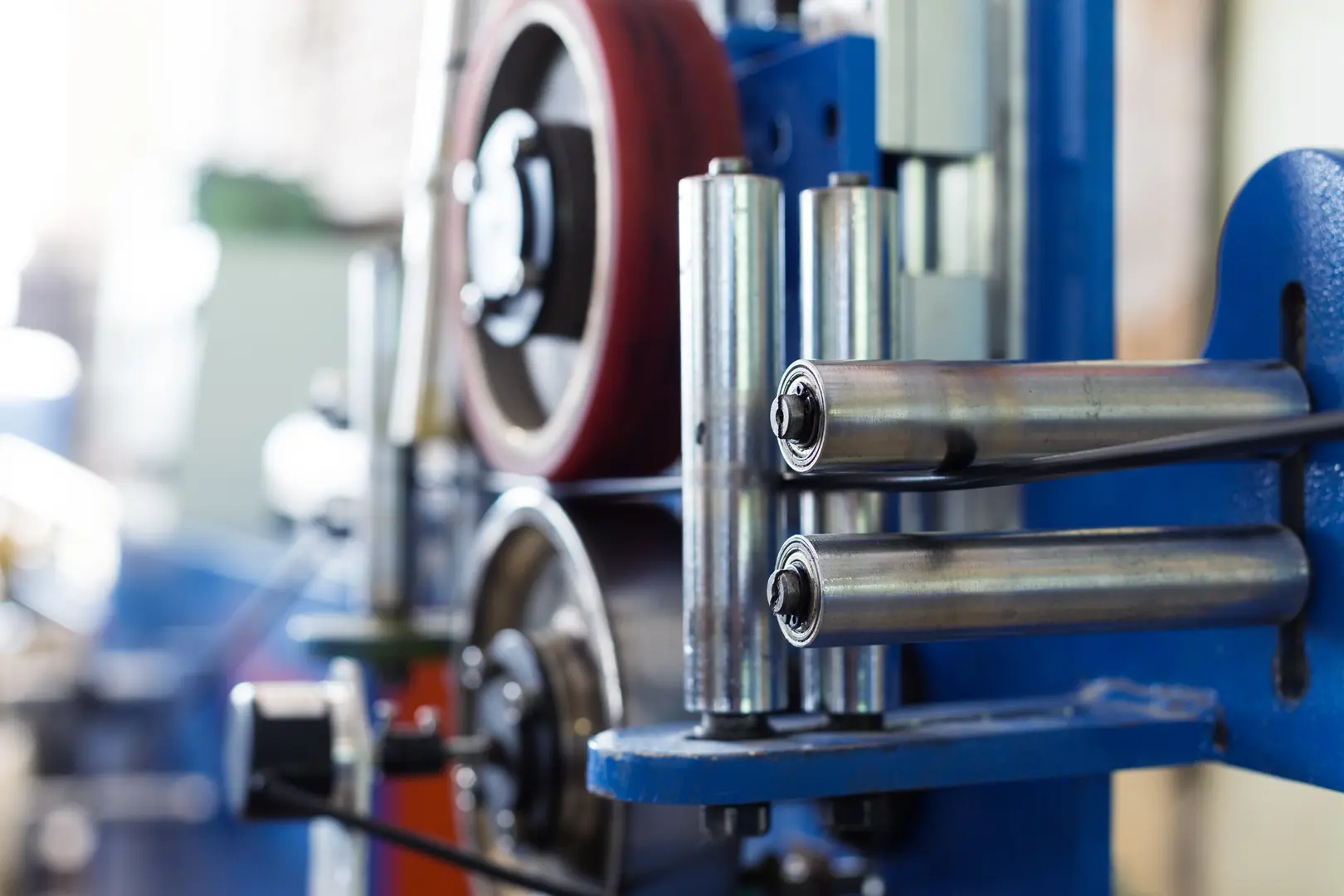

#4 finish stainless steel is a mechanically brushed finish with a moderate reflectivity and a distinct, uniform grain. Its value lies in balancing aesthetic appeal with functional durability, making it essential for applications requiring both corrosion resistance and a consistent visual appearance.

In my role at MFY, I talk with business leaders every day who need reliable materials to keep their operations running smoothly. The #4 finish is one of the most requested, yet it's also a frequent source of supply chain pain. It’s not just a commodity; it’s a critical component where technical precision meets market reality. Let's break down what makes this finish so vital and how you can navigate the complexities of sourcing it in bulk to gain a competitive advantage.

What are the technical specifications of #4 finish stainless steel?

Unsure about the exact specs for #4 finish? Inconsistent surfaces can ruin a project's look and performance. Defining key metrics ensures you get the quality you pay for.

Key technical specifications include a controlled surface roughness (Ra), typically between 0.4 to 0.6 micrometers, and a uniform, directional grain created by abrasive belts. The finish is non-directional, satin, and has a low to moderate reflectivity.

When we talk about #4 finish, we're discussing a precise, engineered surface. It's not enough to simply say "brushed." True #4 finish quality comes down to measurable data and consistency, which is something we obsess over at MFY. The process involves passing the stainless steel sheet or coil under a series of abrasive belts. The grit of these belts is carefully selected to create the desired effect.

Surface Roughness (Ra)

The most critical metric is Surface Roughness, or Ra. This measures the microscopic peaks and valleys on the steel's surface. For a #4 finish, the Ra value is tightly controlled. Too rough, and it can trap contaminants and be difficult to clean. Too smooth, and it loses its characteristic satin look. Achieving a consistent Ra across an entire coil, and from one coil to the next, is the hallmark of a quality producer. This consistency ensures that when you assemble multiple panels on a large architectural project, they all match perfectly.

Grain and Material Grades

The "grain" refers to the fine, parallel lines created by the brushing. While it has a direction, it's designed to be visually uniform and diffuse light, which helps hide fingerprints and minor scratches. This finish can be applied to various stainless steel grades, most commonly 304 and 316.

| Grade | Key Feature | Common Use Case |

|---|---|---|

| 304 | General-purpose, good corrosion resistance | Kitchen appliances, indoor architectural trim |

| 316 | Enhanced corrosion resistance (added Molybdenum) | Marine hardware, outdoor fixtures, chemical plants |

Choosing the right grade is as important as the finish itself. A #4 finish on 316 steel is essential for outdoor or coastal applications where salt and moisture are a concern.

How does #4 finish enhance the properties of stainless steel?

Is a finish just for looks? Believing this overlooks critical performance benefits that can impact your product's lifespan. The #4 finish does more than just look good.

The #4 finish enhances stainless steel by improving its corrosion resistance through a uniform passive layer. Its smooth, brushed surface also makes it easier to clean, more hygienic, and better at hiding minor scratches and fingerprints compared to highly polished finishes.

The true value of a #4 finish extends far beyond its clean, modern aesthetic. The mechanical brushing process actually improves the material's functional performance in several key ways. As a business director, I always advise clients to think about the total lifecycle cost, and the right finish plays a huge role in that calculation.

Corrosion Resistance and Passivation

The stainless steel's inherent corrosion resistance comes from a thin, invisible layer of chromium oxide on its surface, known as the passive layer. The brushing process used to create a #4 finish helps to remove surface impurities and create a more uniform, stable passive layer. This makes the steel less susceptible to localized corrosion, like pitting or crevice corrosion[^1], especially when specified on a robust grade like 316.

Cleanability and Hygiene

The controlled roughness of the #4 finish is a sweet spot for hygiene. Unlike rougher finishes, it doesn't have deep grooves that can trap bacteria, making it easy to wipe down and sanitize. This is why it's the standard in commercial kitchens, food processing plants, and medical facilities. I remember a client who manufactured dairy equipment; they switched from a 2B finish to a #4 finish and saw a measurable reduction in cleaning time and a significant improvement in their hygiene audit scores.

Aesthetic Durability

Compared to a mirror finish (like #8), the #4 finish is incredibly practical. Its satin, grained texture diffuses light, which makes minor scratches, smudges, and fingerprints much less noticeable. This makes it ideal for high-traffic areas like elevator panels, countertops, and public fixtures. It maintains its appearance with minimal maintenance, which is a major selling point for end-users.

What factors affect the availability of bulk stock for #4 finish stainless steel?

Facing unexpected stock shortages for #4 finish? These disruptions can halt production and delay critical projects. Understanding the root causes is the first step to securing your supply.

Bulk stock availability is primarily affected by fluctuating raw material prices (especially nickel), global production capacity at mills, logistical bottlenecks, and shifting market demand. These factors create a volatile environment where supply can tighten unexpectedly, impacting project timelines and costs.

Navigating the global stainless steel market requires a deep understanding of its moving parts. For a specialized product like #4 finish, the challenges are magnified. At MFY, our integrated position in the supply chain gives us a front-row seat to these dynamics, and we work tirelessly to shield our partners from them.

Raw Material Volatility

The price of stainless steel is heavily tied to the price of its raw components, particularly nickel. Sudden spikes in the nickel market[^2], driven by geopolitical events or financial speculation, can instantly impact steel prices and production decisions. Mills may become hesitant to commit to fixed-price, long-term contracts, leading to uncertainty for buyers.

Production Capacity and Lead Times

Creating a #4 finish is a secondary processing step that requires specialized equipment and time. When overall steel demand is high, mills often prioritize producing high-volume, standard-finish coils (like 2B or BA). This can push out lead times for finished products like #4. I recall a client in Germany working on a large architectural facade. A sudden surge in automotive demand caused their local supplier's mill to reallocate production, putting their project in jeopardy. We were able to leverage MFY's dedicated processing lines to secure their material and keep the project on track.

Global Logistics Challenges

Even when the material is produced, it must be shipped. Global shipping container shortages, port congestion, and fluctuating freight costs add another layer of complexity. A delay at a single port can have a ripple effect, causing weeks of delay for a time-sensitive project. This is why having a partner with strong export and logistics expertise is no longer a luxury—it's a necessity.

What are the recommended uses for #4 finish stainless steel?

Unsure if #4 finish is right for your application? Choosing the wrong finish leads to poor performance and aesthetics. Knowing its ideal uses ensures optimal results and value.

#4 finish is highly recommended for architectural applications like wall panels and elevators, commercial kitchen equipment, appliances, and decorative automotive trim. Its blend of durability, cleanability, and aesthetic appeal makes it a versatile choice for high-traffic and visually sensitive areas.

The versatility of the #4 finish is why it has become an industry workhorse. Its balanced properties make it the perfect solution for a wide range of demanding environments. When clients ask me where to use it, I point to applications where aesthetics, durability, and hygiene must all coexist without compromise.

Architectural and Construction

In architecture, appearance and longevity are everything. The #4 finish provides a clean, modern look that is also tough enough to handle public spaces. You see it everywhere: elevator doors, wall cladding, column covers, and storefronts. Its ability to maintain a consistent look across large surfaces makes it a favorite for designers who want a sleek, uniform appearance.

Food Service and Processing

This is the home turf for #4 finish. From restaurant kitchen countertops and backsplashes to large-scale food processing machinery, its hygienic properties are non-negotiable. It can withstand aggressive cleaning chemicals and daily wear-and-tear while providing a surface that is easy to keep sanitary.

Transportation and Automotive

In buses, trains, and even high-end cars, #4 finish is used for decorative trim, kick plates, and interior panels. It offers an upgraded look compared to plastic or aluminum, and its durability means it can handle the scuffs and bumps that come with daily use in a transit environment.

| Application Area | Primary Benefit of #4 Finish |

|---|---|

| Commercial Kitchens | Hygiene and Cleanability |

| Architectural Panels | Aesthetic Consistency and Durability |

| Home Appliances | Fingerprint Hiding and Modern Look |

| Public Transit | Scratch Resistance and Low Maintenance |

How can you efficiently procure #4 finish stainless steel in bulk?

Tired of procurement headaches and unreliable suppliers? A reactive approach leads to high costs and constant uncertainty. A strategic procurement plan provides stability and a competitive edge.

Efficiently procure #4 finish in bulk by partnering with an integrated supplier who controls the supply chain from raw materials to export. Prioritize suppliers with strong production capacity, strategic inventory, and transparent communication to mitigate market volatility and ensure consistent delivery.

In today's market, simply finding the lowest price is a short-sighted strategy that often leads to failure. Efficient procurement is about building resilience and predictability into your supply chain. It’s about risk management. The best way to achieve this is to change how you view your suppliers—see them not as vendors, but as strategic partners.

Partner with an Integrated Supplier

The key is to work with a company that has visibility and control over the entire process. At MFY, our strength comes from our deep integration within a larger group that spans from raw materials to final production and global logistics. This structure means we aren't just a trading desk susceptible to market whims. We can manage production schedules, control quality at every step, and optimize logistics because we are part of the machine. This integration directly translates into more reliable supply and stable pricing for our clients.

The Power of Strategic Stockpiling

A truly valuable partner doesn't just produce to order; they anticipate your needs. We maintain a significant inventory of popular grades and finishes, including #4. This strategic stock acts as a buffer against mill production delays or sudden demand spikes, allowing us to offer much shorter lead times than a typical mill-direct order. For our clients, this means more agility and the ability to respond to opportunities faster.

Demand Forecasting and Communication

The final piece is collaboration. We work closely with our long-term partners to understand their demand forecasts. This open communication allows us to align our production and inventory strategies with their needs, creating a seamless supply chain. It transforms the relationship from a series of transactions into a true partnership focused on mutual growth and stability.

Conclusion

Mastering #4 finish stainless steel requires understanding its technical details and the market forces affecting its supply. Partnering with a resilient, integrated supplier like MFY is the key to navigating this complexity, ensuring you get the quality and quantity you need, right on schedule.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.