Sanitary SS Tube Bending for Food Industry: High-Precision Processing & Finishing

Struggling to meet food safety standards? Contamination risks in processing lines can lead to costly recalls and damage your reputation. High-precision sanitary tube bending[^1] is the solution.

High-precision sanitary stainless steel tube bending is critical for the food industry. It ensures hygienic, crevice-free surfaces that prevent bacterial growth, comply with strict regulations like 3-A and EHEDG, and optimize fluid dynamics for enhanced operational efficiency and product safety.

As the Global Business Director at MFY, I've seen firsthand how the integrity of a food or beverage processing line comes down to the smallest details. The way a tube is bent can be the difference between a pristine, efficient system and a contamination nightmare. It's not just about shaping metal; it's about engineering safety and quality into the very framework of food production. Let's explore why this process is so fundamental.

Where are sanitary stainless steel tubes used in the food industry?

Complex processing systems need clean pathways. Any point of failure can compromise the entire batch. Sanitary stainless steel tubing provides the necessary hygienic, corrosion-resistant solution for product transport.

Sanitary stainless steel tubes are essential in virtually every part of the food and beverage industry. They are used in dairy processing, beverage production lines, liquid food conveyance systems, Clean-in-Place (CIP) systems, and pharmaceutical-grade food supplement manufacturing to ensure product purity.

When we look deeper, the applications are incredibly diverse, and the demand for precision is universal. At MFY, we supply tubes for projects that span the entire sector, and the requirements are always centered on hygiene and flow efficiency. A slight imperfection in a bend can create a dead leg or a crevice, which becomes a breeding ground for microbes. This is why the quality of the bend is just as important as the quality of the steel itself.

Dairy Processing Lines

In the dairy industry, products like milk, yogurt, and cheese are highly susceptible to bacterial contamination. Sanitary tubes are used to move these products from pasteurizers to holding tanks and packaging machines. The smooth, seamless bends we help create ensure there are no areas where milk solids can accumulate and spoil, which is a constant concern for our clients in this space.

Beverage Conveyance

For beverages, from fruit juices to carbonated drinks, maintaining product flavor and preventing contamination is key. High-precision bent tubes create efficient, cleanable pathways that minimize turbulence and pressure drops. This not only protects the product but also improves the efficiency of the entire system, reducing energy consumption for pumping.

Clean-in-Place (CIP) Systems

Perhaps the most demanding application is within CIP systems. These systems are responsible for cleaning the entire processing line without disassembly. The tubes must have a perfect interior finish and precisely engineered bends to ensure that cleaning fluids reach every surface at the correct velocity, effectively removing all residues and sanitizing the equipment for the next production run.

What standards govern high-precision sanitary tube processing?

Ensuring product safety isn't optional. Strict global regulations can feel overwhelming to navigate. Adhering to established sanitary standards is the only way to guarantee compliance and market access.

The primary standards governing sanitary tube processing are the 3-A Sanitary Standards in the U.S., the European Hygienic Engineering & Design Group (EHEDG) guidelines, and the ASME Bioprocessing Equipment (BPE) standard, which all specify criteria for material, surface finish, and design.

I often speak with engineering contractors who are designing new facilities, and their first question is always about compliance. These standards are not just suggestions; they are the foundation of safe food processing design. They provide a clear framework for us as suppliers and for them as integrators. The core principle behind all of them is the elimination of any feature that could harbor microorganisms. This is where the dual emphasis on technical precision and material integrity, a core value at MFY, becomes so important. We don't just bend a tube; we ensure the process preserves the sanitary qualities of the material.

Key Regulatory Frameworks

Understanding these standards helps clarify why every detail matters. They share a common goal but often focus on slightly different aspects of hygienic design.

| Standard | Основной фокус | Geographic Region | Key Requirement Example |

|---|---|---|---|

| 3-A Sanitary Standards | Hygienic design, materials, and fabrication | Primarily North America | Surface finish of Ra <0.8μm, crevice-free design |

| EHEDG | Testable hygienic performance | Primarily Europe | Verifiable cleanability and sterilizability of equipment |

| ASME-BPE | Bioprocessing equipment design | Глобальная | Specifics on materials, welding, and dimensional tolerances |

Following these standards means controlling every step, from selecting the right grade of stainless steel (typically 304L or 316L) to ensuring the bending process doesn't compromise the tube's internal surface finish or its structural integrity.

What are the main challenges in sanitary tube bending and finishing?

Achieving a perfect bend is difficult. Even minor errors in the process can lead to wall thinning, surface damage, or dimensional inaccuracies, compromising the entire system's integrity.

The main challenges include maintaining a uniform tube wall thickness, preventing ovality (distortion of the tube's circular profile), avoiding wrinkles or cracks on the bend's surface, and preserving the sanitary internal finish without introducing scratches or contamination from tooling.

These challenges are not just theoretical. I remember a client in India who was setting up a new fruit juice processing plant. They sourced some locally bent tubes to save costs, but during the commissioning of their CIP system, they found they couldn't achieve proper sanitation. Upon inspection, we discovered the bends had internal wrinkles and a rough finish from improper tooling. These tiny imperfections were trapping pulp and creating a biofilm issue. It was a costly lesson for them, but it highlights how critical mastering these challenges is.

Material Integrity Issues

When a tube is bent, the outer wall (the heel) is stretched and becomes thinner, while the inner wall (the throat) is compressed.

- Wall Thinning: Excessive thinning on the heel weakens the tube, making it susceptible to failure under pressure. It also alters the internal diameter, which can disrupt the calculated flow dynamics of the system.

- Ovality and Wrinkling: If the tube is not properly supported from the inside during bending, it can collapse into an oval shape. The compression on the throat can also cause the material to buckle and form wrinkles. Both issues create areas where product can stagnate and microbes can thrive.

Surface Finish Preservation

The internal surface of a sanitary tube is polished to a very smooth finish (measured in Ra, or Roughness Average) to prevent bacteria from adhering. The bending process, which involves intense pressure and friction from tooling, can easily damage this finish. Any scratch, no matter how small, is a potential harborage point for bacteria and a starting point for corrosion.

How can we overcome these processing and finishing challenges?

These processing challenges seem daunting. The cost of a failed batch or a safety recall is far too high to ignore. Thankfully, proven strategies and advanced techniques can ensure perfect results every time.

Overcoming these challenges requires using advanced bending techniques like mandrel bending to prevent collapse, employing high-quality lubricants to protect surfaces, controlling the bending speed and pressure, and performing post-bending finishing processes like electropolishing to restore and enhance the sanitary finish.

At MFY, our entire approach is built on these strategies. We don't see it as simply bending a tube; we see it as a multi-stage engineering process designed to deliver a component that is both geometrically perfect and hygienically sound. It's about combining the right equipment with deep expertise. This is how we provide our partners with the assurance they need that their systems will perform flawlessly from day one.

Advanced Tooling and Mandrels

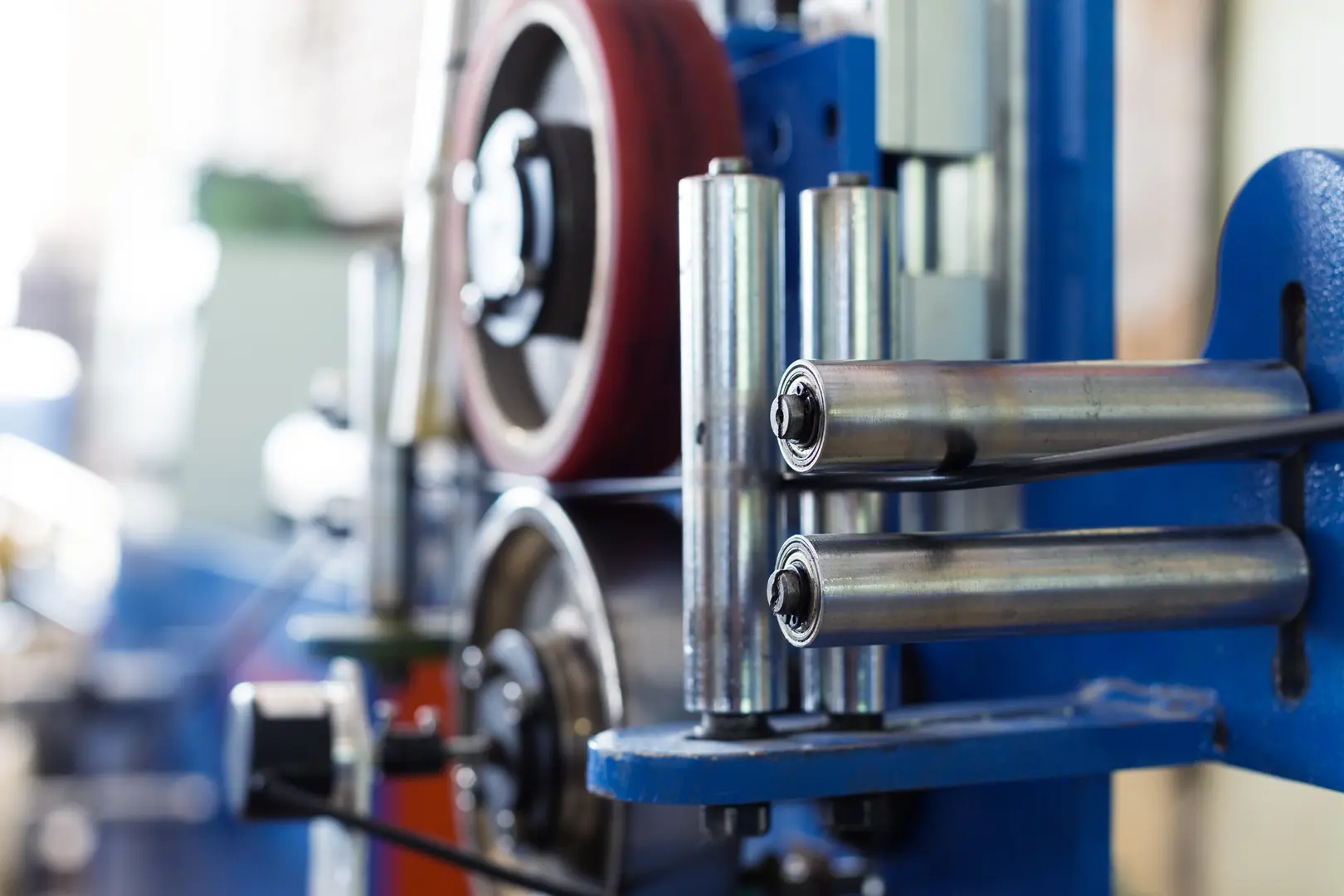

The single most important tool for high-quality tube bending is the mandrel. A mandrel is an articulated rod that is inserted inside the tube during the bending process.

- Mandrel Bending: This technique provides internal support to the tube, preventing it from collapsing into an oval shape and minimizing wall thinning. For sanitary applications, using a non-marring mandrel made from a material like nylon or using polished steel ball mandrels is crucial to avoid scratching the interior surface.

- Wiper Dies: A wiper die is used to support the tube at the point of bending, preventing wrinkles from forming on the inside radius of the bend.

Post-Bending Finishing Processes

Even with the best tooling, the bending process can slightly alter the surface finish. That's why post-bending treatment is non-negotiable for high-purity applications.

- Deburring and Polishing: After bending and cutting, the tube ends must be carefully deburred to remove any sharp edges. The interior of the bend may then be mechanically polished to restore the required Ra value.

- Electropolishing: This is the ultimate step. The bent tube is submerged in an electrolyte bath and an electric current is applied. This process removes a microscopic layer of the surface material, leveling out any peaks and valleys. The result is an ultra-smooth, chromium-rich, passive surface that is exceptionally cleanable and corrosion-resistant.

What innovative techniques are shaping the future of sanitary tube bending?

Staying competitive means constantly improving. Relying on old methods can lead to inconsistencies and inefficiencies. Embracing new technology is the key to achieving the next level of precision.

Innovative techniques shaping the industry include multi-axis CNC (Computer Numerical Control) benders for complex, repeatable geometries, non-contact laser measurement systems for real-time quality control, and the integration of robotics for automated handling, which ensures consistency and reduces contamination risks.

The future is already here. The rise of large-scale, fully automated food processing plants demands a level of component precision that can only be achieved through technology. When a client needs hundreds of identical, complex tube assemblies for a new facility, manual methods are no longer viable. We've invested heavily in these technologies at MFY because they allow us to translate a digital design directly into a perfect physical part, every single time. This is pivotal in optimizing the flow dynamics and equipment longevity that our partners in competitive markets demand.

The Role of CNC Automation

A CNC bender can be programmed with a tube's exact specifications, including multiple bend angles and rotations on different planes. The machine then executes these bends with a degree of accuracy and repeatability that is impossible to achieve manually. This is essential for creating complex manifold systems and ensuring that every component of a large-scale installation fits together perfectly, minimizing the need for on-site adjustments and welds. Fewer welds mean fewer potential failure points and a more hygienic system overall.

In-Situ Quality Control

Modern bending systems are increasingly equipped with integrated measurement technology. Laser probes can scan the tube after each bend to verify its geometry against the original CAD model in real time. If any deviation is detected, the system can automatically correct it on the next part. This immediate feedback loop drastically reduces scrap rates and guarantees that every finished piece meets the tightest tolerances required for sanitary applications.

Заключение

Ultimately, high-precision sanitary tube bending is more than just a fabrication step. It is a critical enabler of food safety, operational efficiency, and innovation in the food and beverage industry, forming the backbone of modern, hygienic processing systems that protect both consumers and brands.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.