Custom Tubing Design: Smart Tips for Cost-Effective Tube Bending

Struggling with high costs on custom tubing projects? Unplanned expenses can hurt your bottom line. Smart design and material choices are the key to cost-effective tube bending.

To design cost-effective custom tubing, focus on simplifying bend designs, selecting appropriate materials, using digital simulation tools for planning, and choosing the right bending technique. This proactive approach minimizes waste, reduces tooling costs, and improves overall production efficiency for your projects.

As the Global Business Director at MFY, I've seen countless projects succeed or fail based on these early decisions. The competitive landscape demands not just quality, but also efficiency. Getting the design right from the very beginning is the most powerful lever you have for controlling costs and ensuring a successful outcome. Let's break down how you can build a smarter, more cost-effective process for your custom tubing needs.

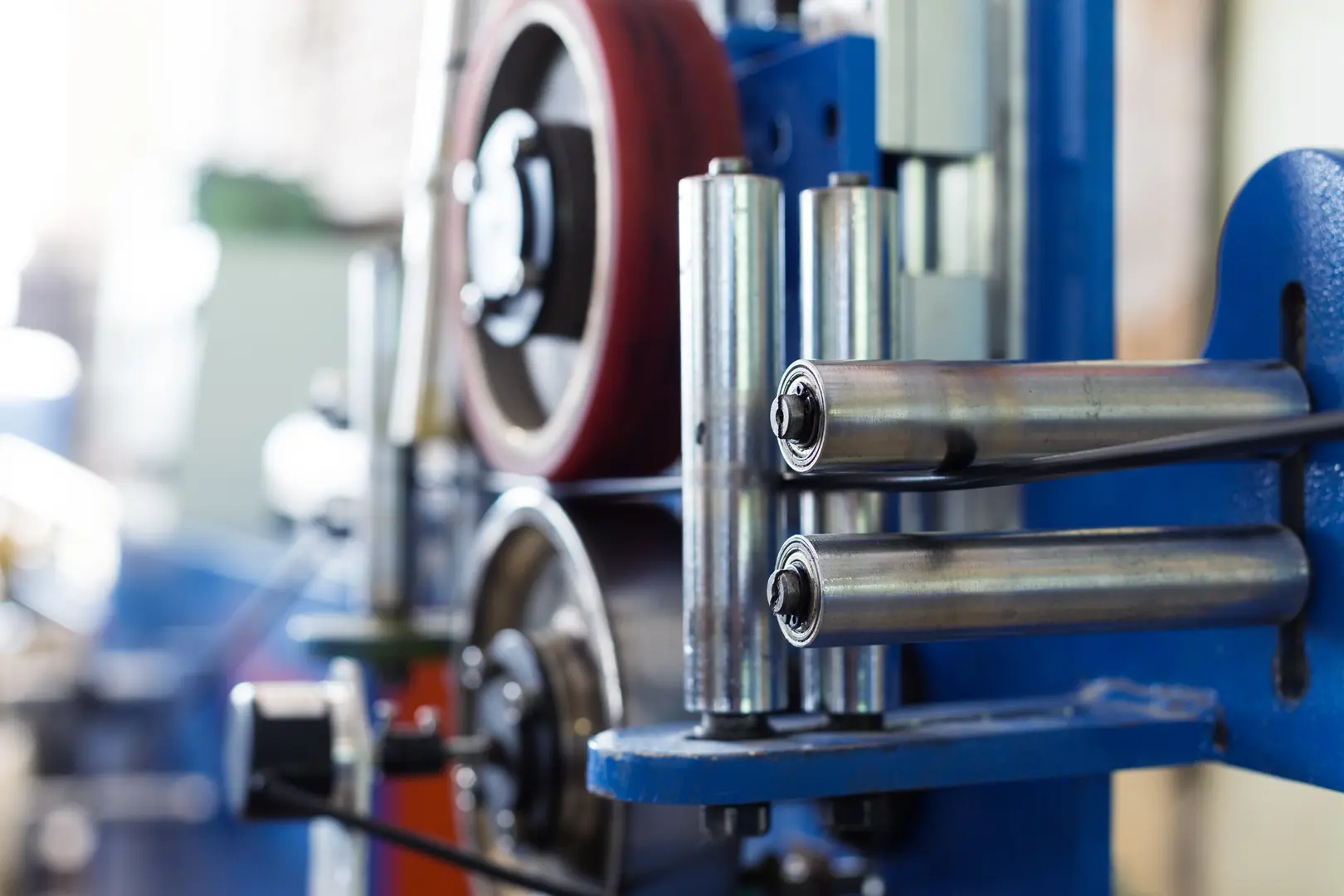

What are the Basics of Tube Bending?

Misunderstanding bending basics is a common problem. This leads to design flaws, material waste, and costly rework. Grasping core principles prevents these common and expensive mistakes.

Tube bending involves using mechanical force to permanently shape tubing. Key factors include the bend radius, wall thickness, and material properties. Understanding these fundamentals is the first step to creating designs that are both functional and manufacturable without defects.

At its core, tube bending is a controlled deformation process. When we bend a tube, the material on the outside of the bend is stretched and thinned, while the material on the inside is compressed and thickened. If not managed correctly, this can lead to defects like wrinkling on the inside radius or cracking on the outside. I remember a client in Germany who specified a very tight bend radius for a stainless steel part without considering the material's limits. This resulted in a high scrap rate[^1] until we collaborated with their engineers to slightly increase the radius, solving the problem instantly and saving them a significant amount on their production run.

Key Bending Terminology

Understanding the language of tube bending is critical for clear communication between designers and fabricators. A small misunderstanding can lead to big problems.

| Term | Definition | Impact on Cost |

|---|---|---|

| Center Line Radius (CLR) | The distance from the center of the bend to the center line of the tube. | Tighter radii often require more advanced tooling (like mandrels) and slower processes, increasing cost. |

| Толщина стенок | The thickness of the tube's wall. | Thinner walls are more prone to collapse or wrinkling during bending, requiring more support. |

| Пластичность | A material's ability to be stretched or deformed without breaking. | Higher ductility allows for tighter bends and more complex shapes with a lower risk of failure. |

| Springback | The tendency of a material to return to its original shape after bending. | Must be accounted for by over-bending. Inconsistent springback increases process variability and scrap. |

Grasping these basics is not just academic; it’s the foundation upon which all cost-saving strategies are built. It allows you to design parts that are inherently easier and cheaper to produce.

How Can You Plan Your Custom Tubing Design for Efficiency?

An inefficient design process is a huge issue. It wastes time and resources before production even starts. Strategic planning and modern digital tools are the solution.

Plan for efficiency by simplifying geometries, standardizing bend radii where possible, and minimizing the number of bends. Most importantly, leverage digital simulation tools to predict material behavior and validate your design before any physical prototyping, saving significant time and cost.

The single biggest shift I've seen in our industry is the move from a "prototype and test" model to a "simulate and validate" one. This is where the real competitive advantage lies today, especially in demanding sectors like automotive and aerospace. The root cause of this trend is a convergence of powerful software and market pressure for greater efficiency and sustainability. Companies can no longer afford the material waste and long lead times of traditional trial-and-error methods. By investing in digital design capabilities upfront, you are not just saving money on one project; you are building a more agile and resilient manufacturing process for the future.

The Power of Digital Simulation

Advanced digital tools, like Finite Element Analysis (FEA)[^2], are game-changers. They allow us to create a digital twin of the tube and the bending process. We can simulate the stresses, predict potential thinning or wrinkling, and optimize the bend parameters all on a computer. This means we can identify and fix potential failures before a single piece of steel is touched. This digital-first approach directly minimizes waste and accelerates the development cycle, aligning with the industry's push toward more eco-efficient operations.

Strategic Design Simplification

While simulation helps manage complexity, simplification is often the most direct path to cost savings.

| Design Choice | Inefficient Approach | Cost-Effective Approach |

|---|---|---|

| Bend Radii | Multiple, unique radii on one part. | Standardize radii to 2-3x the tube's outer diameter. Use the same radius where possible. |

| Number of Bends | Many complex bends close together. | Minimize the number of bends and ensure sufficient straight length between them. |

| Tolerances | Unnecessarily tight tolerances. | Specify tolerances only as tight as the application truly requires. |

By thinking like a fabricator during the design phase, you can eliminate unnecessary costs associated with custom tooling and complex machine setups.

How Do You Select the Right Materials for Tube Bending?

Choosing the wrong material is a frequent problem. This can cause catastrophic production failures and long-term performance issues. The solution is to match material properties to design requirements.

Select materials based on their formability, ductility, and yield strength. Stainless steel grades like 304 and 316 are popular for their excellent balance of strength and bendability. Always consider the application's environment and the material's cost.

Your material choice has a ripple effect on the entire project. It influences the required bending technique, the tooling, the cycle time, and the final part's performance. For example, some materials experience significant work hardening, meaning they become harder and stronger as they are bent. This must be accounted for in the process, as it requires more force and can affect subsequent bends on the same part. At MFY, we often advise clients on material selection early on. A small increase in upfront material cost for a more formable grade of stainless steel can often lead to much larger savings in production due to lower scrap rates and faster cycle times.

Key Material Properties for Bending

It's not just about picking a material; it's about understanding its behavior.

- Ductility & Elongation: These are the most critical factors. High ductility and elongation mean the material can stretch more on the outside of the bend without cracking.

- Yield Strength: This is the point at which the material starts to deform permanently. A lower yield strength generally makes a material easier to bend.

- Corrosion Resistance: For many applications, especially in the chemical, marine, or food industries, this is a non-negotiable requirement that will guide your selection.

Common Materials Comparison

| Материал | Bendability | Устойчивость к коррозии | Relative Cost | Common Use Case |

|---|---|---|---|---|

| Stainless Steel 304 | Превосходно | Очень хорошо | Средний | Structural, food processing, automotive |

| Stainless Steel 316 | Очень хорошо | Превосходно | Высокий | Marine, medical, chemical |

| Углеродистая сталь | Хорошо | Poor (requires coating) | Низкий | General fabrication, structural |

| Aluminum | Превосходно | Хорошо | Средний | Aerospace, automotive, lightweight structures |

Choosing the right material is a balancing act between performance, manufacturability, and cost.

What are the Most Cost-Effective Bending Techniques?

Using an overly complex or ill-suited bending method is a common issue. This inflates costs and production time unnecessarily. You must choose the simplest technique that meets your quality needs.

The most cost-effective techniques depend on volume and complexity. Rotary draw bending offers high precision for complex parts, while roll bending is efficient for large radii. Mandrel bending is essential for tight-radius bends to prevent collapse.

The technique and the tooling are two sides of the same coin. I once worked with an aerospace client who had designed a part with two very similar, but not identical, bend radii. By simply adjusting the design to make those two radii identical, they eliminated the need for a whole set of expensive custom tools and a separate machine setup. This small change saved them thousands of dollars on a single component. This story highlights a crucial point: your design choices directly dictate the manufacturing techniques and tooling required, which are major cost drivers.

Matching Technique to Application

There is no single "best" method; the right choice depends entirely on your project's specific requirements.

| Bending Method | Описание | Best For | Фактор стоимости |

|---|---|---|---|

| Rotary Draw Bending | Tube is clamped and drawn around a rotating bend die. Often uses a mandrel. | High-quality, tight-radius, complex bends. | High initial tooling cost, but efficient for high volume. |

| Roll Bending | Tube is passed through a series of three rollers to create a large-radius curve. | Large radii, coils, and spirals. Simple curves. | Low tooling cost, suitable for a wide range of sizes. |

| Compression Bending | A stationary bend die is used, and a clamp block wipes the tube around it. | Simple bends where minor deformation on the inside radius is acceptable. | Low-cost tooling, fast process. |

The Critical Role of Tooling

Tooling is a significant investment. Mandrels, which are inserted into the tube to prevent collapse, are especially critical for thin-walled tubes or tight bends. While they add cost, they are often essential for achieving the required quality. The key takeaway is to design parts that can be made with standard, existing tooling whenever possible. This simple strategy can slash your project's upfront costs and lead times.

How Do You Evaluate the Success of Your Tube Bending Process?

Many teams fail to measure their process success. This means you can't identify areas for improvement or find hidden cost savings. The solution is to implement clear quality control metrics.

Evaluate success by measuring key metrics: dimensional accuracy against the design, surface finish quality, and the scrap rate. Consistent quality control checks and feedback loops are crucial for process optimization and ensuring long-term cost-effectiveness.

Evaluation isn't just about catching defects at the end of the line; it's about creating a continuous improvement loop. This is where MFY's value of "continuous evolution" really comes into play. The data you collect from production is incredibly valuable. We encourage our partners to feed this real-world data—like actual springback measurements or observed material thinning—back into their initial digital simulation models. This makes the models smarter and more accurate for the next project. It transforms your manufacturing process from a series of one-off jobs into a learning system that gets more efficient and cost-effective over time.

Key Performance Indicators (KPIs) for Bending

You can't improve what you don't measure. Focus on these simple but powerful metrics:

- First Pass Yield (FPY): What percentage of parts are made correctly the first time, with no rework? This is a primary indicator of process health.

- Scrap Rate: The percentage of parts that must be discarded. This is a direct measure of material and time waste.

- Dimensional Accuracy: How closely do the finished parts match the CAD model? Using tools like CMM machines or laser scanners provides objective data.

- Cycle Time: How long does it take to produce one finished part? Reducing this directly impacts throughput and labor costs.

By tracking these KPIs, you can pinpoint inefficiencies and make data-driven decisions to optimize your operation, reinforcing your market leadership and delivering consistent value to your clients.

Заключение

Ultimately, cost-effective tube bending is not about cutting corners; it's about smart, proactive design. By integrating digital planning, selecting the right materials, and choosing efficient techniques, you can achieve superior results while protecting your bottom line. This is a strategic advantage in today's demanding market.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.