Bright Annealed SS Tubing: Medical/Semiconductor Standards & Craftsmanship

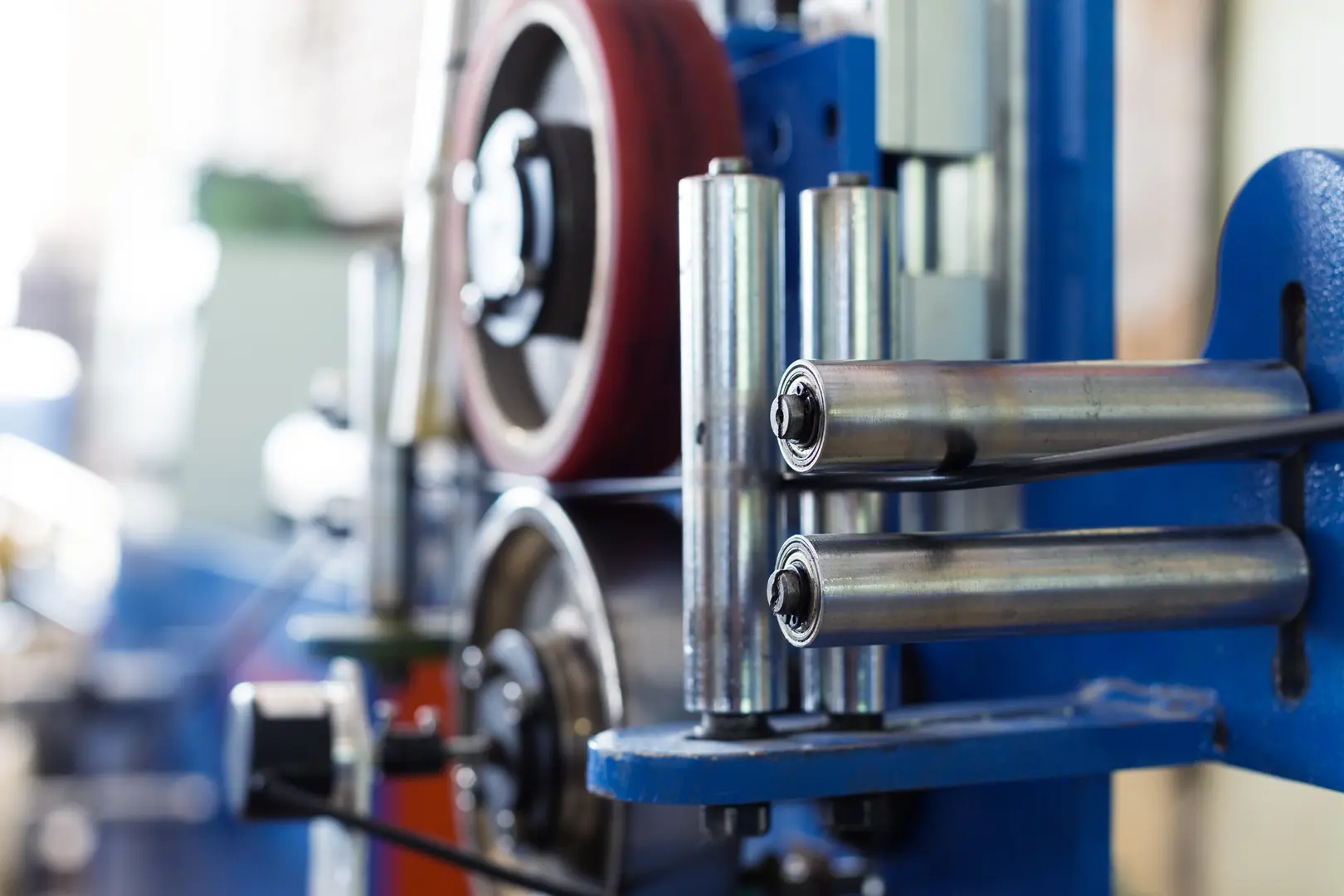

High-tech industries face immense pressure for material purity. Contamination can derail entire projects. Bright annealed stainless steel tubing provides the pristine, reliable solution these demanding sectors absolutely require.

Bright annealed (BA) stainless steel tubing is critical because its exceptionally smooth, non-reactive, and corrosion-resistant surface prevents contamination and ensures process integrity. This makes it essential for high-purity applications like medical devices and semiconductor manufacturing, where precision and cleanliness are non-negotiable.

In my role at MFY, I've seen firsthand how the right material choice can be the difference between success and failure in these critical industries. It's not just about a shiny tube; it's about the underlying quality and precision that protects sensitive processes. Let’s explore why this material is so vital, the standards that govern it, and the craftsmanship required to produce it.

What is the significance of bright annealed SS tubing in medical and semiconductor industries?

These industries demand absolute purity in their processes. Even microscopic flaws or contaminants can ruin a batch of semiconductors or compromise patient safety. BA tubing provides the necessary safeguard.

The significance lies in its ultra-clean internal surface, which minimizes particle generation and bacterial growth. This ensures the purity of gases and liquids in semiconductor manufacturing and maintains sterility and biocompatibility in medical devices, directly impacting product quality and safety.

The importance of this material cannot be overstated. In both medical and semiconductor fields, the environment must be controlled with extreme precision. The tubing used to transport fluids and gases is a primary point of contact and, therefore, a potential source of contamination. This is where the unique properties of bright annealed stainless steel become indispensable.

Medical Applications

In the medical field, materials must be biocompatible and easy to sterilize. BA tubing is used in everything from surgical instruments to diagnostic equipment and drug delivery systems. Its smooth surface, often with a roughness average (Ra)[^1] of less than 0.5 micrometers, resists bacterial adhesion and biofilm formation. This makes cleaning and sterilization processes far more effective, which is a critical factor in preventing hospital-acquired infections. I remember a client developing a new dialysis machine who switched to our BA tubing; they reported a significant improvement in the machine's long-term sterility and a reduction in maintenance cycles, all thanks to the superior surface finish.

Semiconductor Manufacturing

The semiconductor industry operates on an even smaller scale, where a single microscopic particle can destroy an entire silicon wafer worth thousands of dollars. BA tubing is used to transport ultra-high purity (UHP) gases[^2] needed for processes like chemical vapor deposition. The mirror-like interior finish prevents particles from the tube wall from flaking off and contaminating the gas stream. The chromium oxide passive layer formed during the annealing process also provides excellent corrosion resistance against aggressive gases.

| Характеристика | Standard SS Tubing | Bright Annealed SS Tubing | Impact in High-Tech Industries |

|---|---|---|---|

| Отделка поверхности | Dull, rougher | Mirror-like, ultra-smooth | Reduces particle shedding and bacterial growth. |

| Purity | Standard | High purity, free of oxides | Prevents contamination of sensitive processes. |

| Устойчивость к коррозии | Хорошо | Превосходно | Ensures long-term integrity with aggressive chemicals. |

How do current standards influence the production of bright annealed SS tubing?

Simply claiming a product is "high quality" is not enough. Non-compliance with industry standards means rejected batches, regulatory hurdles, and a complete loss of trust with clients.

Current standards, such as ASTM A269/A270 for sanitary applications and SEMI specifications for semiconductors, dictate every aspect of production. They define precise requirements for chemical composition, dimensional tolerances, surface roughness (Ra), and inspection methods, ensuring consistency and safety.

Standards are the backbone of our industry. They provide a common language for quality and performance that both producers and users can rely on. At MFY, we don't just meet these standards; we build our entire production philosophy around them. They are not a checklist to be completed but a baseline from which we strive to exceed expectations. Adherence to these strict guidelines is what allows a manufacturer in China to reliably supply a medical device company in Germany or a semiconductor fab in the United States.

Material Composition and Purity

Standards like ASTM A270 specify the exact percentages of elements like chromium, nickel, and molybdenum in the steel (e.g., 316L). They also set strict limits on impurities like sulfur, which can affect weldability and corrosion resistance. We start with sourcing certified raw materials from our integrated supply chain to guarantee that the chemical foundation of our tubing is flawless from the very beginning.

Dimensional and Surface Tolerances

For high-tech applications, consistency is key. Standards define acceptable ranges for outer diameter, wall thickness, and straightness. More importantly, they specify the maximum allowable internal surface roughness, often measured in Ra. Achieving a low Ra value requires specialized polishing and a tightly controlled bright annealing process.

| Standard | Key Requirement | Application Focus | Why It Matters |

|---|---|---|---|

| ASTM A270 | Specifies sanitary-grade tubing. Often requires <0.51 µm Ra. | Pharmaceutical, Biotech, Food | Ensures cleanability and prevents bacterial contamination. |

| SEMI F20 | Governs materials for UHP gas distribution systems. | Semiconductor | Defines purity levels to prevent wafer contamination. |

| ASME BPE | Bioprocessing Equipment Standard. | Pharmaceutical, Biotech | Provides strict guidelines for design and manufacturing. |

What challenges are faced in meeting industry-specific requirements for SS tubing?

The goal is perfection, but achieving it is incredibly difficult. Tiny inconsistencies in wall thickness or a microscopic flaw on the surface can lead to catastrophic failures in the final application.

The primary challenges include maintaining an ultra-low and consistent surface roughness (Ra) across entire production runs, achieving extremely tight dimensional tolerances, and completely preventing any form of contamination or oxidation during the high-temperature annealing process.

Producing standard stainless steel tubing is a relatively straightforward industrial process. But producing tubing that meets the stringent demands of the medical and semiconductor industries is another matter entirely. It requires a level of precision and control that pushes the boundaries of manufacturing technology and expertise. The margin for error is virtually zero.

Controlling Surface Roughness (Ra)

Achieving a mirror-like finish inside a long, narrow tube is a significant technical hurdle. It involves multiple stages of mechanical polishing and электрополировка[^3], each of which must be perfectly executed. The bright annealing process itself is the final, critical step. The tube is heated in a controlled atmosphere furnace, typically with hydrogen, to prevent any oxidation that would tarnish the surface. Any fluctuation in temperature or atmospheric composition can ruin the finish.

Maintaining Dimensional Consistency

When tubing is connected using compression or orbital-welded fittings, as is common in semiconductor plants, even minor variations in the outer diameter can cause leaks. Maintaining a consistent wall thickness is equally important for uniform pressure handling and flow dynamics. This requires state-of-the-art drawing and rolling mills and continuous, real-time monitoring throughout the production process.

| Вызов | Potential Defect | Impact in Medical/Semiconductor |

|---|---|---|

| Improper Annealing | Surface oxidation, scaling | Particle generation, contamination. |

| Inconsistent Polishing | High Ra value, scratches | Bacterial growth, compromised fluid dynamics. |

| Drawing Flaws | Inconsistent wall thickness | Uneven pressure resistance, fitting failures. |

| Contamination | Embedded particles | Process contamination, device failure. |

What strategies can be employed to overcome production challenges in SS tubing manufacturing?

These complex challenges demand sophisticated solutions. Relying on outdated methods or simple visual checks is a recipe for failure when dealing with high-stakes applications.

Overcoming these challenges requires a multi-faceted strategy: investing in advanced machinery like controlled-atmosphere furnaces and laser micrometers, implementing a rigorous multi-stage quality control system, and fostering a culture of deep technical expertise and craftsmanship among the production team.

At MFY, we view these challenges not as obstacles, but as opportunities to demonstrate our commitment to excellence. Our strategy is built on the belief that quality cannot be inspected into a product; it must be built into it from the very start. This philosophy is supported by our fully integrated supply chain, which gives us unparalleled control over every variable, from the raw materials to the final packaging.

Investment in Advanced Technology

We utilize state-of-the-art bright annealing furnaces with precise atmospheric and temperature controls to ensure a perfect, oxide-free surface every time. During the drawing process, real-time laser measurement systems continuously monitor the tube's diameter and wall thickness, allowing for immediate micro-adjustments. This is a huge step up from traditional periodic manual checks. I saw the impact myself when we installed our latest system; our dimensional variance was reduced by over 30% in the first six months.

A Culture of Rigorous Quality Control

Technology is only part of the solution. Our quality assurance protocol involves multiple checkpoints. We use non-destructive testing methods like eddy current and ultrasonic testing to detect any subsurface flaws that are invisible to the naked eye. Every batch of tubing is accompanied by a detailed material test report (MTR)[^4] that provides full traceability and certifies its chemical and physical properties, ensuring our clients have complete confidence in the product they receive.

How does craftsmanship impact the quality and reliability of bright annealed SS tubing?

In an age of automation, it's easy to overlook the human element. But technology is a tool, and its effectiveness is maximized by a skilled operator who understands the nuances of the process.

Craftsmanship translates technical specifications into a superior physical product. It's the experienced operator who fine-tunes machinery, the inspector who spots subtle imperfections, and the engineer who optimizes processes beyond what a manual dictates, ensuring ultimate quality and reliability.

I firmly believe that craftsmanship is our ultimate differentiator. A machine can follow a program, but it cannot apply judgment or experience. In the production of high-precision tubing, that human touch is what elevates a good product to a great one. It embodies the convergence of stringent standards and what I like to call artisanal engineering.

The Human Element in Precision

Our senior technicians have decades of experience. They can often detect a potential issue just by the sound of a machine or the feel of the material. They understand how a slight change in humidity or ambient temperature might affect the polishing process and make adjustments that an automated system would miss. This deep, intuitive knowledge prevents minor deviations from becoming major defects down the line. It's a level of control that goes beyond the numbers on a spec sheet.

Beyond the Spec Sheet

Craftsmanship is also about a commitment to quality that permeates our entire company culture. It's about taking pride in producing a component that will be used in life-saving medical equipment or in the creation of the next generation of microchips. This mindset ensures that every employee, from the furnace operator to the packaging specialist, handles the product with the care and attention it deserves. While a machine ensures we meet the standard, our people's craftsmanship ensures we exceed it.

| Аспект | Automated Process | Craftsman-Overseen Process |

|---|---|---|

| Problem Solving | Follows pre-programmed logic. | Adapts intuitively based on experience. |

| Quality Assessment | Relies on sensor data. | Combines sensor data with expert visual/tactile inspection. |

| Process Optimization | Requires reprogramming. | Makes continuous, subtle improvements in real-time. |

| Final Product | Meets specifications. | Meets specifications with superior consistency and finish. |

Заключение

Bright annealed stainless steel tubing is more than a simple component; it is a critical enabler for innovation in the medical and semiconductor industries. Achieving the required quality demands a synthesis of advanced technology, strict adherence to global standards, and the irreplaceable touch of human craftsmanship.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.