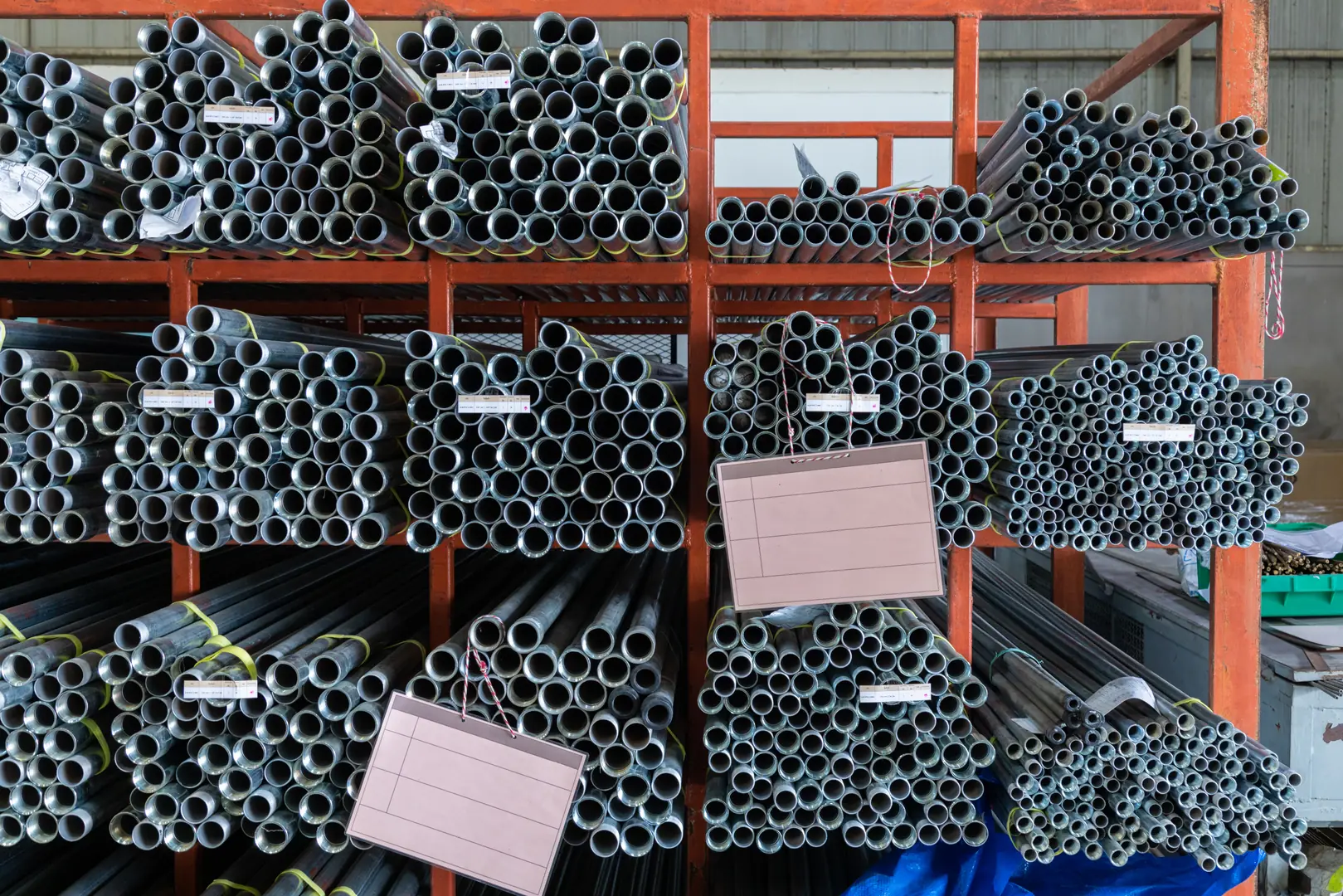

Bulk Supply: 304 SS Welded Pipes for Global Projects – Specifications & Quotes

Global projects demand reliable materials. Supply chain disruptions are a constant threat. Mastering specifications and sourcing is your key to success and avoiding costly delays.

Mastering the bulk supply of 304 stainless steel welded pipes requires a deep understanding of technical specifications, current market trends, and a partnership with a supplier offering an integrated supply chain. This ensures quality, cost-effectiveness, and on-time delivery for large-scale international projects.

As the Global Business Director at MFY, I've seen firsthand how the right material supply strategy can make or break a multi-million dollar project. The complexities of international construction are immense, but the fundamentals of securing your supply chain remain constant. It’s about more than just placing an order; it's about building a resilient foundation for your project's success. Let's break down how you can navigate the world of 304 stainless steel welded pipes and turn a potential headache into a competitive advantage.

Why Are 304 SS Welded Pipes Essential for Global Construction Projects?

Projects need durable, long-lasting materials. Poor choices lead to corrosion and failure. 304 SS welded pipes offer the perfect balance of performance and cost.

304 stainless steel welded pipes are essential due to their excellent corrosion resistance, high strength-to-weight ratio, durability, and cost-effectiveness. This makes them ideal for structural and fluid transport applications in diverse global construction environments, from buildings to water treatment plants.

When we dive deeper, the value proposition of 304 stainless steel becomes even clearer. For any project manager or engineer, material selection is a critical decision point balancing cost, performance, and longevity. The 304 grade hits a sweet spot that few other materials can match. Its chromium-nickel composition provides robust protection against a wide range of corrosive environments, which is why we see it used so extensively in everything from architectural elements exposed to the weather to the complex piping networks within industrial facilities. I remember a client in Brazil working on a major water utility upgrade. They initially considered other materials but switched to 304 welded pipes once they modeled the long-term maintenance savings. The initial investment was slightly higher, but the total cost of ownership was significantly lower, protecting their project budget for decades. This is the kind of strategic thinking that defines successful projects.

Key Performance Attributes

The versatility of 304 SS welded pipes stems from a few core characteristics. Its excellent formability and weldability mean it can be easily fabricated on-site or in a workshop to meet precise project specifications. This adaptability reduces waste and installation time. Furthermore, its hygienic properties make it the default choice for food processing, pharmaceutical, and water treatment applications, where preventing contamination is non-negotiable.

Applications in Modern Infrastructure

- Structural and Architectural: Handrails, building facades, and support columns.

- Fluid and Gas Transport: Water and wastewater systems, chemical processing lines, and natural gas distribution.

- Automotive and Transportation: Exhaust systems and structural components.

What Are the Current Global Demand Trends for 304 SS Welded Pipes?

Staying ahead of market trends is difficult. Misjudging demand can hurt your procurement strategy. Understanding key drivers gives you a competitive edge.

Current demand is driven by rapid urbanization, significant investments in green infrastructure like water treatment facilities, and stricter building and environmental regulations worldwide. Emerging economies in Asia and the Middle East are particularly strong growth markets for 304 SS welded pipes.

At MFY, we analyze these trends daily because they directly impact our clients' projects and our supply chain strategy. The global push towards sustainability is no longer just a talking point; it's a powerful economic driver. We see this clearly in the types of projects being funded. Governments and private investors are pouring capital into "green infrastructure"—projects that are not only new but also environmentally responsible and built to last. This is where 304 stainless steel shines. Its durability means less replacement, and its high recyclability aligns perfectly with circular economy principles[^1]. A few years ago, we worked with a large contractor on a desalination plant[^2] in the Middle East. The project's financing was tied to strict environmental and material longevity standards. 304 SS welded pipes were specified from the start because they met both the corrosion resistance requirements of a coastal environment and the sustainability criteria of the international lenders. This is a perfect example of how regulatory frameworks and green investments are shaping our industry.

The Push for Green Infrastructure

The demand for resilient construction solutions is growing as we face more extreme environmental challenges. 304 stainless steel's resistance to corrosion and fire makes it a key component in building infrastructure that can withstand the test of time, reducing the environmental impact of frequent repairs and replacements.

Regional Demand Drivers

| Region | Key Demand Drivers |

|---|---|

| Asia-Pacific | Rapid urbanization, industrial expansion, infrastructure upgrades. |

| Europe | Stringent environmental regulations, renovation projects, high-tech manufacturing. |

| North America | Water infrastructure renewal, commercial construction, energy sector. |

| Middle East | Desalination plants, large-scale construction, oil & gas projects. |

What Are the Main Challenges in Bulk Supplying 304 SS Welded Pipes?

Sourcing bulk materials is complex. You face risks from quality inconsistency to logistical nightmares. These challenges can derail project timelines and budgets.

The main challenges include ensuring consistent material quality across large batches, navigating complex international logistics and tariffs, managing price volatility of raw materials like nickel, and aligning supplier production schedules with demanding project timelines. These issues require a robust and agile supply partner.

In my experience, the single biggest fear for a project manager is uncertainty. When you're ordering hundreds of tons of material, that uncertainty can be magnified. The bulk supply of stainless steel pipes is fraught with potential pitfalls. I recall a conversation with a new client in India who had a nightmare experience with a previous supplier. They received a large shipment for a critical manufacturing facility, but the wall thickness of the pipes was inconsistent. Some were within spec, but many were not. This created a massive bottleneck, forcing them to halt production and re-source the material, which led to significant financial penalties. This story is all too common, and it highlights the absolute necessity of rigorous quality control, especially at scale. A supplier's promise of a low price is worthless if they cannot guarantee that every single pipe in a 500-ton order meets the exact same standard as the first. This is where a supplier’s internal processes and commitment to quality are truly tested.

Quality and Consistency at Scale

For bulk orders, you need a supplier who can provide Mill Test Certificates (MTCs)[^3] for every batch and who has a proven track record of maintaining tight tolerances. This isn't just about meeting a standard on paper; it's about having the production discipline to execute it flawlessly across a massive production run.

Navigating Logistical Hurdles

Beyond quality, the logistics of moving tons of steel across continents are incredibly complex. You have to contend with shipping schedules, customs clearance, and potential port delays. A supplier with a deep understanding of global trade and established logistics partnerships can navigate these waters smoothly, providing you with clear and reliable delivery timelines.

What Are Effective Strategies for Meeting Global Supply Needs?

Meeting global supply demands feels overwhelming. A fragmented approach leads to inefficiency. A strategic partnership with an integrated supplier is the solution.

Effective strategies involve partnering with a supplier that has a fully integrated supply chain, from raw materials to final delivery. This provides transparency, better cost control, and greater reliability. Leveraging digital platforms for order tracking and communication is also crucial for efficiency.

The most effective strategy I've seen in my career is to simplify your supply chain by choosing a partner who manages the complexity for you. This is the core philosophy behind MFY's business model. Instead of you having to coordinate with a raw material provider, a production mill, a logistics company, and a trading agent, you work with one partner who controls the entire process. This strategic alignment of capabilities is our greatest strength. An integrated model gives us direct control over quality at every step, from the selection of raw materials to the final inspection before shipping. It also allows us to manage costs more effectively by cutting out unnecessary intermediaries. For our clients, this translates into greater peace of mind, predictable pricing, and the ability to make one phone call to get an update on their entire order. It transforms the procurement process from a series of transactions into a genuine partnership focused on a shared goal: successful project completion.

The Power of an Integrated Supply Chain

This model is built for the demands of modern global projects. It provides the agility to respond to changes and the resilience to absorb shocks in the supply chain, ensuring your materials arrive on time and on spec.

Fragmented vs. Integrated Supply Chain

| Feature | Fragmented Supply Chain | Integrated Supply Chain (MFY Model) |

|---|---|---|

| Communication | Multiple points of contact | Single point of contact |

| Quality Control | Inconsistent, hard to trace | Consistent, end-to-end control |

| Cost Structure | Multiple markups, hidden fees | Transparent, more competitive pricing |

| Accountability | Diffused, blame-shifting | Clear and direct accountability |

Vague specifications lead to incorrect quotes. This causes project delays and cost overruns. A clear, detailed request for quotation (RFQ) is essential.

Navigate this by providing a detailed RFQ that includes standards (ASTM, EN), dimensions (OD, wall thickness, length), finish, and quantity. Work with suppliers who offer transparent, itemized quotes and can provide Mill Test Certificates (MTCs) to verify compliance and quality.

The quotation process is where precision and transparency become paramount. A quote is only as good as the information it's based on. Time and again, I see projects get off on the wrong foot because the initial Request for Quotation (RFQ) was incomplete. A simple request for "304 welded pipe" is not enough. Are you working to an ASTM A312 standard[^4] for high-temperature service, or an ASTM A269 standard for general service? What is the exact outside diameter (OD) and wall thickness required, and what are the acceptable tolerances? What surface finish do you need? These details are not trivial; they are fundamental to ensuring you get the right product at the right price. A professional supplier should not only provide a clear quote but also act as a consultant, helping you refine your specifications to ensure they are complete and accurate. At MFY, we are moving towards more streamlined digital quoting processes to make this exchange of information faster and more transparent for our clients worldwide.

Crafting the Perfect Request for Quotation (RFQ)

To get an accurate and competitive quote, your RFQ must be thorough. This clarity at the beginning prevents costly misunderstandings and delays later on.

Essential Elements of a 304 SS Welded Pipe RFQ

| Element | Description | Example |

|---|---|---|

| Standard | The manufacturing specification the pipe must meet. | ASTM A312, EN 10217-7 |

| Dimensions | Outside Diameter (OD), Wall Thickness (WT), and Length. | OD 114.3mm, WT 3.05mm, Length 6m |

| Quantity | The total amount required, specified by weight (tons) or length (meters). | 250 Tons |

| Finish | The required surface finish of the pipe. | Annealed & Pickled (AP), Bright Annealed (BA) |

| End Type | How the ends of the pipe should be finished. | Plain Ends (PE), Beveled Ends (BE) |

| Testing Requirements | Any additional non-destructive or destructive testing needed. | Hydrostatic Test, Eddy Current Test |

Conclusion

Sourcing 304 SS welded pipes for global projects requires more than just a good price. It demands a strategic partner. By focusing on clear specifications and an integrated supply chain, you ensure your project's success from the ground up. MFY is here to be that partner.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.