How does Welding Affect the Properties of Stainless Steel? Technical Analysis & Solution

Welding can compromise stainless steel's core properties. This hidden degradation leads to premature failures and costly risks. Understanding the science behind it is the first step to ensuring lasting integrity.

Welding introduces intense, localized heat that alters the steel's microstructure, particularly in the Heat-Affected Zone (HAZ). This can reduce corrosion resistance, decrease mechanical strength, and introduce residual stresses, impacting the material's long-term performance if not managed correctly.

As the Global Business Director at MFY, I've seen firsthand how a seemingly simple weld can become the single point of failure in a multi-million dollar project. The truth is, joining two pieces of stainless steel is a complex metallurgical process. It's not just about melting and fusing metal; it's about managing a thermal event that can fundamentally change the material you paid for. In this article, I'll break down what happens to stainless steel during welding and, more importantly, how we can control the process to ensure the final product is as strong and reliable as the original material. Let's dive in.

What are the common effects of welding on stainless steel properties?

You specify a high-performance material for a reason. But after welding, unseen changes can weaken its best qualities. Let's identify the most common effects to watch out for.

The most common effects include reduced corrosion resistance due to chromium carbide precipitation, altered mechanical properties like toughness and ductility in the Heat-Affected Zone (HAZ), the introduction of residual stresses, and potential distortion or warping of the final component.

When we discuss the effects of welding, we're primarily concerned with the changes that occur in and around the weld seam. This area, known as the Heat-Affected Zone (HAZ), is where the base metal didn't melt but was exposed to extremely high temperatures. This exposure is enough to trigger significant changes. I remember a case with a client in the chemical processing industry in Germany. They were seeing failures in their stainless steel tanks near the weld lines, far sooner than expected. The issue wasn't the quality of our steel but the welding procedure that had compromised its inherent properties.

Microstructural Changes

The primary effect is a change in the steel's microstructure. The rapid heating and cooling cycle can cause the grains within the metal to grow larger. A coarser grain structure generally leads to a reduction in toughness and ductility, making the material more brittle in that specific area. This is a critical concern in applications subjected to dynamic loads or low temperatures, where material toughness is paramount for preventing catastrophic fractures.

Corrosion Resistance Degradation

Perhaps the most significant concern for stainless steel is the loss of its signature corrosion resistance. This phenomenon, known as "sensitization[^1]," occurs when chromium carbides precipitate along the grain boundaries in the HAZ. This process effectively robs the surrounding area of the chromium it needs to form the protective passive oxide layer. Without this layer, the steel becomes vulnerable to intergranular corrosion[^2], a localized attack that can rapidly compromise the integrity of the structure.

| Property Affected | Common Effect in the HAZ | Primary Cause |

|---|---|---|

| Corrosion Resistance | Decreased, potential for intergranular corrosion | Chromium carbide precipitation (sensitization) |

| Mechanical Strength | Reduced toughness and ductility | Grain growth and altered microstructures |

| Structural Integrity | Introduction of residual stresses, potential distortion | Non-uniform heating and cooling |

| Appearance | Discoloration (heat tint) | Surface oxidation at high temperatures |

What causes changes in stainless steel properties during welding?

The material often looks perfectly fine after welding. But hidden thermal processes are at play, silently altering its internal structure. Understanding the root cause is key to preventing these issues.

The primary cause is the intense, localized heat input from the welding process. This thermal cycle alters the carefully balanced microstructure of the stainless steel, leading to phenomena like sensitization, grain growth, and the formation of different phases within the Heat-Affected Zone (HAZ).

At its core, stainless steel is a precise alloy, primarily of iron, chromium, and often nickel and carbon. Its properties are a direct result of its crystalline structure, which is achieved through carefully controlled manufacturing processes. Welding disrupts this balance with brute force. The extreme heat from the welding arc creates a steep temperature gradient, where the metal goes from ambient temperature to its melting point and back down in a matter of seconds. This thermal shock is the root cause of all the property changes we observe.

The Role of the Heat-Affected Zone (HAZ)

The HAZ is the battleground where the material's original properties fight against the thermal effects of welding. It's the transitional area between the molten weld metal and the unaffected base metal. Because the HAZ doesn't melt, it doesn't benefit from any filler metal that might be added, but it still endures temperatures high enough to trigger significant microstructural changes. The size of the HAZ is directly proportional to the heat input; higher heat input over a longer duration results in a larger, more problematic HAZ.

Sensitization and Carbide Precipitation

The most critical phenomenon is sensitization, which typically occurs in austenitic stainless steels (like 304 and 316) when heated within a specific temperature range.

| Temperature Range (°C) | Metallurgical Effect | Consequence |

|---|---|---|

| 450°C - 850°C | Chromium combines with carbon to form chromium carbides at the grain boundaries. | Depletes chromium needed for the passive layer, causing sensitization. |

| > 900°C | Grain growth occurs. | Reduces toughness and ductility. |

| > 1400°C | Melting occurs in the weld pool. | Properties are determined by filler metal and cooling rate. |

When the steel in the HAZ cools slowly through the 450°C to 850°C range, carbon atoms migrate to the grain boundaries and bond with chromium atoms. This locks up the chromium, preventing it from forming the passive, corrosion-resistant oxide film on the surface. This is why a perfectly good sheet of stainless steel can suddenly become susceptible to rust and corrosion right next to the weld.

How does welding affect the mechanical strength of stainless steel?

You expect a strong, unified component after fabrication. But the weld itself can inadvertently become the weakest point in the entire structure. Let's examine how welding truly impacts mechanical integrity.

Welding can reduce mechanical strength by creating a Heat-Affected Zone (HAZ) with a coarser grain structure, which can lower toughness and ductility. It can also introduce residual stresses that may lead to premature fatigue cracking or stress corrosion cracking under load.

While we often focus on corrosion, the impact on mechanical properties is just as critical, especially in structural applications. A weld is not just a joint; it's a composite structure consisting of the weld metal, the fusion zone, and the HAZ, each with distinct mechanical properties. In an ideal world, the strength of the welded joint would match or exceed that of the base metal. However, the thermal cycle of welding often creates a localized area—the HAZ—that is mechanically weaker. I’ve consulted on projects where pressure vessels failed during hydro-testing, not because the steel was faulty, but because the HAZ couldn't handle the stress.

Impact on Toughness and Ductility

As mentioned, the high temperatures in the HAZ can cause the microscopic grains of the steel to grow. In metallurgy, larger grain sizes are generally associated with lower toughness—the material's ability to absorb energy and deform without fracturing. This means the area around the weld may become more brittle than the rest of the material. This is a major safety concern in applications involving impacts, vibrations, or cyclic loading, as it creates a preferential path for crack propagation.

The Problem of Residual Stress

As the weld pool cools and solidifies, it shrinks. The surrounding base metal, which is cooler, resists this shrinkage. This internal tug-of-war creates locked-in residual stresses that can be as high as the material's yield strength. These stresses are a hidden danger. They can lead to distortion (warping), but more critically, they lower the component's resistance to fatigue and can initiate stress corrosion cracking (SCC), a failure mechanism where a combination of tensile stress and a corrosive environment causes sudden, brittle failure.

| Property | Unaffected Base Metal | Heat-Affected Zone (HAZ) | Typical Change |

|---|---|---|---|

| Grain Size | Fine | Coarse | Negative |

| Toughness | High | Lower | Negative |

| Ductility | High | Lower | Negative |

| Residual Stress | Low | High | Negative |

What solutions exist to mitigate the negative effects of welding on stainless steel?

The risks of poor welding are clear and significant. Ignoring them leads to costly rework, reputational damage, and potential failures. Fortunately, proven solutions exist to protect your investment and ensure reliability.

Solutions include selecting the correct welding process with controlled heat input (like TIG or laser welding), using low-carbon "L" grade stainless steels, applying proper pre-heating, and performing post-weld heat treatments like annealing or stress-relieving to restore material properties.

The goal isn't to avoid welding; it's to weld smarter. At MFY, we don't just supply steel; we provide solutions. A core part of that is advising our partners on how to maintain the integrity of our materials during fabrication. Mitigating the negative effects of welding involves a three-pronged approach: choosing the right material, controlling the welding process, and treating the material after welding. By mastering these areas, we can turn a potential weak point into a seamless, robust joint.

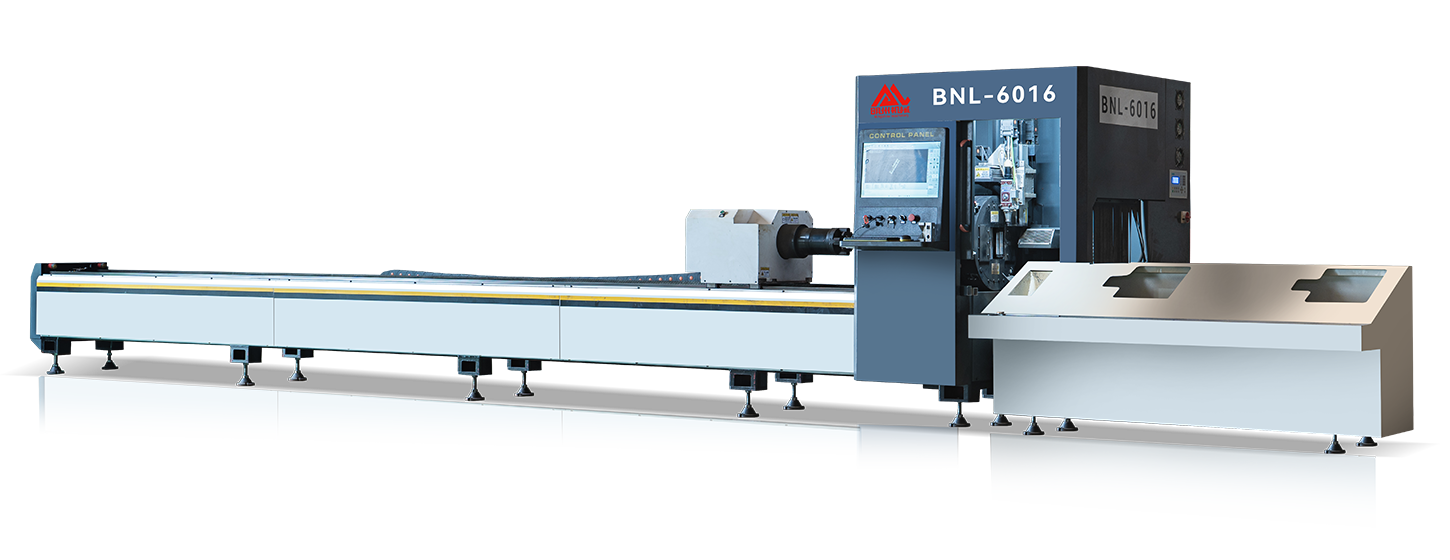

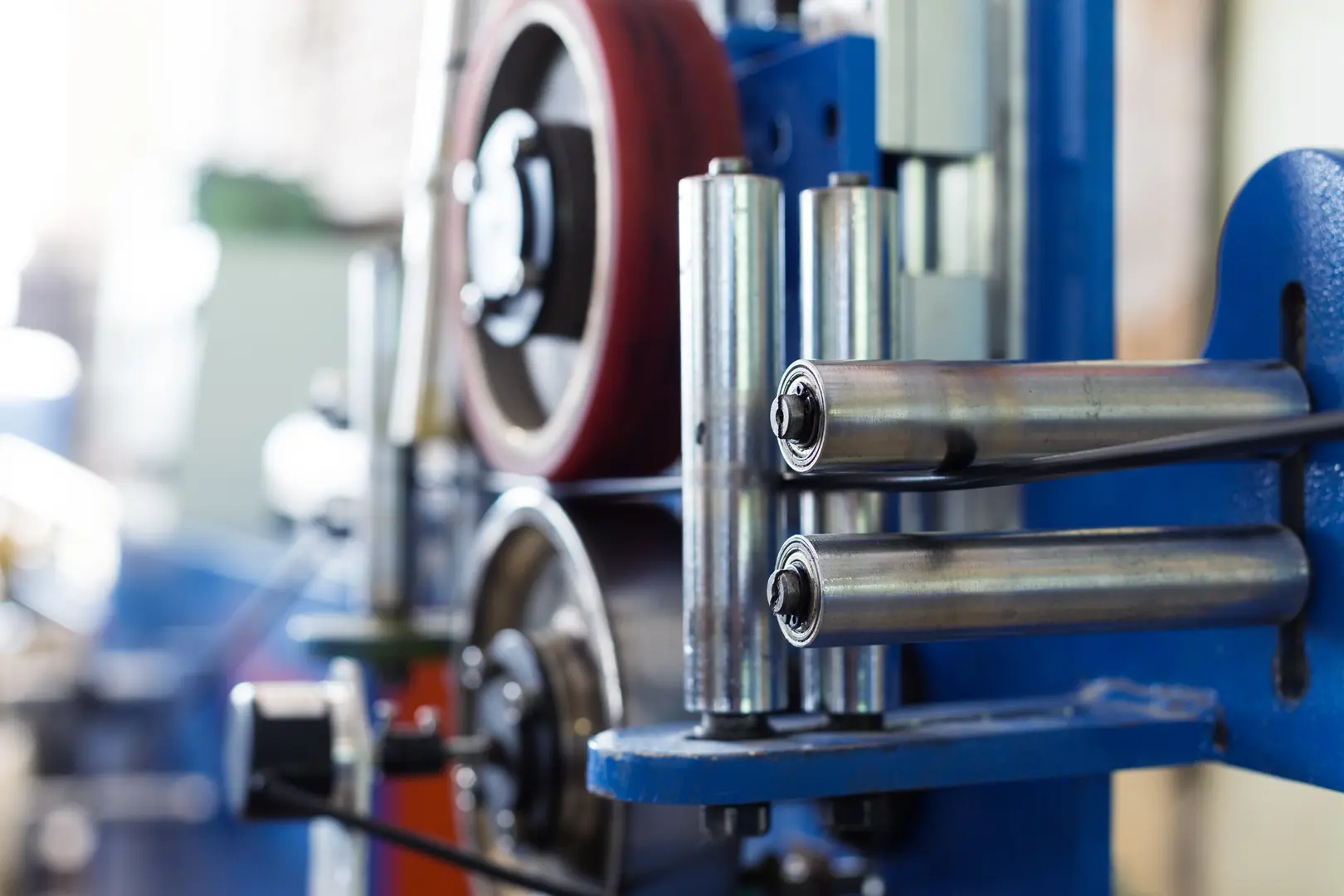

Advanced Welding Techniques

The fundamental problem is heat input. Therefore, the most effective solutions involve processes that minimize it. Techniques like Gas Tungsten Arc Welding (TIG)[^3] offer excellent control, while more advanced methods like Laser Beam Welding and Electron Beam Welding are even better. These high-energy-density processes deliver intense heat to a very small area, resulting in a much narrower HAZ and faster cooling rates. This significantly reduces problems like grain growth and sensitization. While the initial investment is higher, the long-term reliability and reduction in post-weld treatments often provide a strong return.

Material Selection and Post-Weld Heat Treatment (PWHT)

The simplest solution often starts with material selection. Using low-carbon grades of stainless steel, such as 304L or 316L, drastically reduces the risk of sensitization because there is less carbon available to form chromium carbides. For applications where this isn't possible, a post-weld heat treatment is the answer.

- Annealing: This involves heating the entire component to a high temperature (e.g., above 1040°C) and then cooling it rapidly. This dissolves any chromium carbides that have formed and refines the grain structure, effectively resetting the material's properties.

- Stress Relieving: A lower-temperature heat treatment used to reduce the residual stresses locked into the material after welding, which is crucial for preventing stress corrosion cracking.

What are the best practices for welding stainless steel to maintain its integrity?

Knowing the solutions is only half the battle. Improper execution during the welding process can still lead to failure. Following a clear checklist of best practices ensures success every time.

Best practices include meticulous surface preparation and cleaning, using the correct filler material, controlling heat input and interpass temperature, ensuring proper gas shielding to prevent oxidation, and conducting post-weld cleaning to remove contaminants and restore the passive layer.

Excellence in fabrication comes down to discipline and process. Over the years, we've seen that the most successful projects are the ones that treat welding not as a simple joining task, but as a precise technical procedure. Adhering to best practices is non-negotiable for achieving the performance and longevity that stainless steel is known for. It protects the material, the component, and ultimately, your business.

Pre-Weld Preparation

Success begins before the arc is ever struck. The area to be welded must be completely free of any contaminants like oil, grease, paint, or dirt. Using a dedicated stainless steel wire brush is essential to avoid cross-contamination from carbon steel. The joint design must also be correct to ensure full penetration without requiring excessive heat.

Execution and Post-Weld Care

During the weld, control is everything. Here are the key steps we emphasize with our partners:

- Use the Right Filler Metal: Always use a filler metal that is compatible with the base metal, often with a slightly higher alloy content to compensate for any dilution.

- Control Heat Input: Use the lowest possible amperage and fastest travel speed that still achieves a quality weld. Avoid wide, weaving motions.

- Monitor Interpass Temperature: For multi-pass welds, ensure the workpiece cools sufficiently between passes to prevent excessive heat buildup.

- Maintain Gas Shielding: Use a high-purity inert gas (like Argon) with the proper flow rate to protect the molten weld pool and the hot HAZ from oxygen in the atmosphere.

- Post-Weld Cleaning: After welding, the joint must be thoroughly cleaned to remove slag and heat tint (oxidation). This is often done through grinding, brushing, or chemical processes like pickling and passivation, which are essential for restoring the corrosion-resistant passive layer.

Conclusion

Welding is a critical process that fundamentally alters stainless steel. By understanding its effects and implementing proper controls, advanced techniques, and post-weld treatments, we can ensure the final product retains the strength and corrosion resistance that make this material so valuable in modern industry.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.