Seamless Pipe Bending: Purpose, High-Precision Cold Methods & Quality Standards

Struggling with complex piping layouts? The need for precise, durable bends creates engineering headaches. At MFY, we provide solutions that ensure structural integrity and perfect flow for any application.

Seamless pipe bending is a fabrication process that shapes pipes without a welded seam into specific geometries. High-precision cold methods are crucial for maintaining the material's strength and dimensional accuracy, which is vital for performance in critical applications like automotive, aerospace, and high-pressure fluid systems.

Understanding this process is key to optimizing your projects. It’s not just about changing a pipe's direction; it’s about preserving its core qualities to guarantee safety and efficiency. As the Global Business Director at MFY, I’ve seen firsthand how mastering this technology separates the good from the great. Let’s explore why this matters for your business.

Why is Understanding the Purpose of Seamless Pipe Bending So Critical?

Need to route fluids or gases efficiently? Complex systems demand bends, but poor quality can cause failure. The purpose is to create custom pathways without compromising the pipe's integrity.

The primary purpose of seamless pipe bending is to alter the direction of a pipeline to fit specific design requirements. It is essential for creating continuous, leak-proof systems that maintain structural strength, which is impossible to achieve with standard fittings that introduce potential weak points.

Diving deeper into this topic reveals its true importance. It's not merely a convenience; it's a fundamental requirement for modern engineering. The goal is to achieve a specific geometry while ensuring the final product is as strong—or even stronger in some aspects due to work hardening[^1]—than the original straight pipe. I remember a client in the aerospace sector who was struggling with system failures. Their issue wasn't the material but the multiple welded joints in their fluid lines. By switching to precisely bent seamless pipes, they eliminated numerous potential leak points, enhanced system reliability, and reduced overall weight. This is where the real value lies. The process ensures that the flow characteristics within the pipe remain optimal, minimizing turbulence and pressure drops that can occur with sharp, jointed elbows. This efficiency is paramount in high-performance applications where every bit of energy counts.

Key Functional Objectives

The purpose extends beyond simple directional changes. It encompasses several key objectives that are critical for system performance and longevity.

- Structural Integrity: Bending maintains a continuous material structure, avoiding the weak points introduced by welds or mechanical joints.

- Flow Efficiency: Smooth, gradual bends reduce fluid friction and pressure loss compared to standard fittings, improving overall system efficiency.

- Design Flexibility: It allows engineers to create complex, space-saving layouts that would be impossible with pre-fabricated parts alone.

Application-Specific Demands

Different industries leverage bending for unique reasons, highlighting its versatility.

| Industry | Primary Purpose of Bending | Key Benefit |

|---|---|---|

| Automotive | Creating custom exhaust systems and fluid lines. | Weight reduction and improved performance. |

| Aerospace | Fabricating hydraulic and fuel lines. | High reliability and elimination of leak points. |

| Construction | Forming structural elements and conduit pathways. | Architectural freedom and strength. |

| Energy | Building pipelines for oil, gas, and steam. | Enhanced safety and long-term durability. |

Ultimately, understanding the purpose is about recognizing that a well-executed bend is an integral part of a high-performance system, not just a piece of bent metal.

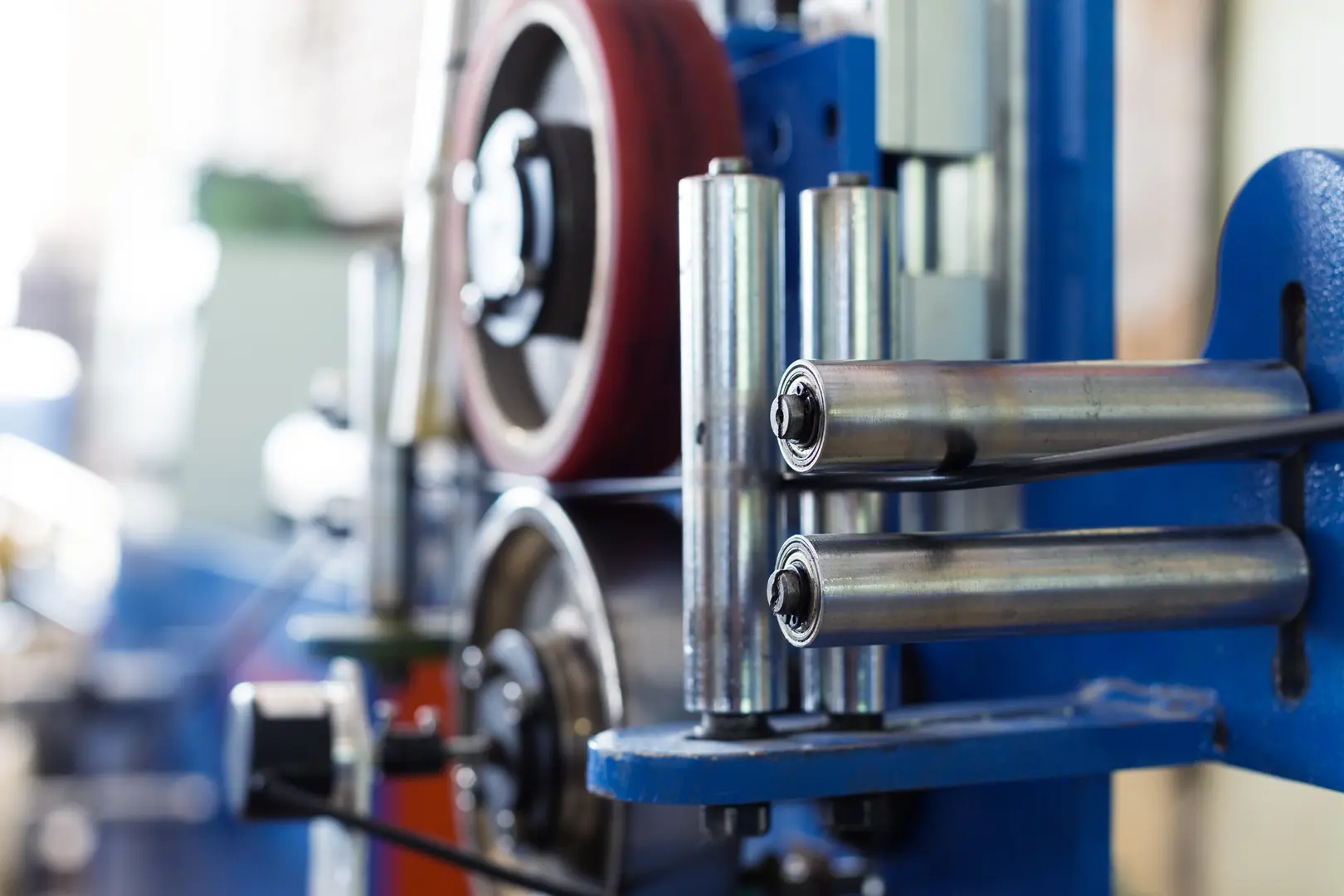

What Are the Current High-Precision Cold Bending Techniques?

Are you concerned about heat-treating after bending? Hot bending can alter material properties, introducing risks. Cold bending techniques preserve the pipe's original strength, delivering precision without compromise.

Current high-precision cold bending techniques include rotary draw bending, ram bending, and roll bending. Rotary draw bending is the most precise method, using dies and a mandrel to support the pipe internally, preventing collapse and ensuring a smooth, accurate bend for tight-radius applications.

Let’s dive deeper into these methods. At MFY, we rely heavily on the most advanced techniques because our clients in sectors like automotive and construction demand perfection. Precision isn't a luxury; it's a requirement. The choice of technique depends entirely on the application's specific needs, such as the bend radius, wall thickness, and required dimensional accuracy. While simpler methods like ram bending are fast and cost-effective for less critical applications, they don't offer the same level of control. For the complex geometries required in modern manufacturing, rotary draw bending is the gold standard. This method gives us incredible control over the process, allowing us to prevent common defects like wall thinning on the outer radius and wrinkling on the inner radius. We achieve this by using a combination of specialized tooling.

Breakdown of Key Cold Bending Methods

Each technique offers a different balance of precision, speed, and cost. Understanding them is key to selecting the right process for your project.

- Rotary Draw Bending: This is our go-to for high-precision work. It clamps the pipe and draws it around a rotating bend die. An internal mandrel prevents the pipe from collapsing, and a wiper die prevents wrinkles. This combination ensures a high-quality, smooth bend with minimal deformation. It's ideal for tight radii and thin-walled tubes.

- Roll Bending: This method uses three rollers to create large-radius bends, perfect for structural applications, arches, and coils. The pipe is passed through the rollers, and the distance between them is adjusted to control the bend's radius. It's excellent for creating curves over long sections of pipe.

- Ram Bending (or Press Bending): This is one of the simplest and oldest methods. A hydraulic ram forces the pipe against two pivot points. While it's fast and inexpensive, it offers less control over the pipe's cross-section and is generally used for non-critical applications where some ovality[^2] is acceptable.

Tooling is Everything

The quality of a cold bend is directly tied to the quality of the tooling.

| Tooling Component | Function in Rotary Draw Bending |

|---|---|

| Bend Die | Defines the radius of the bend. |

| Clamp Die | Holds the straight section of the pipe to the bend die. |

| Pressure Die | Applies pressure to the pipe to keep it against the bend die. |

| Mandrel | Supports the inside of the pipe to prevent collapse (ovality). |

| Wiper Die | Supports the inside radius of the bend to prevent wrinkling. |

By mastering these techniques and investing in top-tier tooling, we ensure every bend meets the stringent standards our clients expect.

What Challenges Arise in Maintaining Quality Standards for Seamless Pipe Bending?

Worried about bends failing inspection? Defects like wall thinning or wrinkling can compromise your entire project. Maintaining consistent quality across thousands of bends is a significant operational challenge.

The main challenges in maintaining quality standards are controlling wall thinning on the outer bend, preventing wrinkling on the inner bend, and managing springback. These issues can compromise the pipe's structural integrity, pressure rating, and dimensional accuracy, leading to costly rework or failures.

Overcoming these challenges is what separates an expert supplier from the rest. At MFY, we see these not as problems, but as variables to be controlled through process mastery. I’ve seen projects delayed for weeks because a batch of bent pipes failed quality control. The issue often stems from a "one-size-fits-all" approach to bending. The reality is that every material grade, wall thickness, and bend radius requires a unique set of parameters. Springback, for instance, is the tendency of the pipe to partially return to its original shape after the bending force is removed. This effect varies with material type and hardness, so we have to precisely calculate the degree of over-bending required to achieve the final target angle. This requires deep material knowledge and sophisticated machine control.

Common Defects and Their Root Causes

Understanding the "why" behind defects is the first step to preventing them.

- Wall Thinning: During bending, the material on the outer radius (the extrados) is stretched. Excessive thinning can weaken the pipe, reducing its ability to withstand pressure. This is often caused by an improper mandrel setup or too tight of a bend radius for the material.

- Wrinkling (or Crinkling): The material on the inner radius (the intrados) is compressed. If not properly supported by a wiper die and mandrel, this compressive force can cause the material to buckle and form wrinkles, which act as stress concentrators and impede flow.

- Ovality: This refers to the distortion of the pipe's circular cross-section during bending. While some ovality is unavoidable, excessive distortion can affect the pipe's fit-up with other components and its pressure-holding capacity. It's typically caused by inadequate internal support from the mandrel.

The Role of Material Properties

The material itself is a major variable. A 304 stainless steel pipe will behave differently than a 316L pipe under the same conditions due to differences in ductility and work-hardening rates.

| Material Challenge | Description | Mitigation Strategy |

|---|---|---|

| Work Hardening | The material becomes harder and less ductile as it's bent. | Use appropriate lubrication and control bending speed. |

| Ductility Limits | Materials with low ductility are more prone to cracking. | Select appropriate bend radii and consider material grade. |

| Springback Variation | Inconsistent material hardness leads to inconsistent springback. | Calibrate machines for each material batch; use advanced controls. |

Effectively managing these challenges requires a holistic approach that combines skilled operators, precise machinery, and a deep understanding of material science.

What Are the Effective Solutions for Overcoming These Bending Challenges?

Are you seeking reliable, defect-free bends? Inconsistent results can derail production schedules and inflate costs. The solution lies in a combination of advanced technology, rigorous process control, and deep expertise.

Effective solutions include using advanced CNC bending machines with closed-loop feedback, employing high-quality, application-specific tooling (like multi-ball mandrels), and implementing robust process simulation software. These tools allow for precise control over bending parameters to mitigate defects and compensate for springback in real-time.

Let's dive deeper into how we turn these challenges into triumphs. At MFY, we don't just bend pipe; we engineer solutions. A few years ago, we worked with a major construction contractor who needed thousands of identical, complex bends for a building façade. Their previous supplier had a high rejection rate due to inconsistent springback. We solved this by using our CNC benders, which are equipped with sensors that measure the bend angle in real-time and automatically adjust the process to compensate for any material variations. This is what we call "intelligent bending." Furthermore, before we even bend the first piece of physical pipe, we run the entire process through simulation software. This allows us to predict potential issues like wrinkling or excessive thinning and optimize the tooling and machine settings in a virtual environment. This "digital twin" approach saves an enormous amount of time and material, ensuring we get it right the first time.

The Technology-Driven Approach

Technology is the cornerstone of modern, high-quality bending.

- CNC (Computer Numerical Control) Benders: These machines provide unparalleled repeatability and precision. We can program complex multi-bend sequences, and the machine executes them flawlessly every time. Modern CNC benders can control multiple axes simultaneously, enabling the creation of highly intricate parts in a single setup.

- Simulation Software: Programs like ABAQUS or DEFORM allow us to simulate the entire bending process. We input the material properties, pipe dimensions, and tooling geometry, and the software predicts stresses, strains, and potential defects. This is a powerful tool for process optimization and troubleshooting.

- Advanced Mandrel Technology: The mandrel is critical for internal support. For very thin-walled tubes or tight-radius bends, we use multi-ball mandrels (e.g., a mandrel with several linked balls). These provide flexible yet firm support that conforms to the shape of the bend, drastically reducing the risk of ovality and collapse.

The Human Element: Expertise and Process Control

Technology alone is not enough. It must be wielded by experts.

| Solution Element | Description | Impact on Quality |

|---|---|---|

| Skilled Operators | Technicians trained in both machine operation and material science. | Can identify subtle issues and make real-time adjustments. |

| Rigorous QC | In-process and final inspection using laser scanners and gauges. | Ensures every part meets dimensional tolerances. |

| Proper Lubrication | Using the right lubricant between the pipe and tooling. | Reduces friction, prevents galling, and improves surface finish. |

By integrating these advanced technologies with deep institutional knowledge, we provide our clients with the confidence that every bend is a perfect bend. This is how we contribute to sustainable manufacturing—by minimizing waste and energy consumption through precision.

What Are Our Technical Recommendations for Ensuring High-Quality Bends?

How can you guarantee every bend meets your specifications? Leaving quality to chance is not an option. You need a clear, actionable framework to ensure consistency and reliability in your supply chain.

Our key recommendations are: clearly define bend specifications (radius, angle, and tolerances), select the right material and bending method for the application, and partner with a supplier who utilizes advanced inspection technologies like laser scanning for 100% verification.

Let's dive into the practical steps that ensure success. As the person responsible for MFY's global business, I insist that our production and quality teams follow a strict protocol. This isn't just internal procedure; it's a promise to our clients. A clear technical specification is the foundation of any successful project. It's not enough to say "a 90-degree bend." We need to know the centerline radius (CLR), the acceptable wall thinning percentage, the maximum allowable ovality, and the precise angle tolerances. This level of detail removes ambiguity and sets a clear target for production. I often tell my team, "If you can't measure it, you can't manage it." That’s why we’ve invested heavily in non-contact inspection technologies. After bending, a part can be verified against its original CAD model in seconds using a 3D laser scanner. This provides a complete dimensional report and a color map showing any deviations, ensuring that what we ship is exactly what the client designed.

The Pre-Production Checklist

Success begins long before the first pipe is bent.

- Collaborative Design Review (DFM): We work with our clients' engineers to review their designs for manufacturability (DFM). Sometimes a small change to a bend radius can significantly improve quality and reduce cost without affecting the part's function.

- Material Certification and Testing: We verify the material certificates for every batch of seamless pipe. If required, we can perform additional tensile or hardness tests to confirm its properties and predict its behavior during bending.

- Tooling Selection and Maintenance: Based on the DFM review and material properties, we select or custom-design the optimal tooling. All our tooling is regularly inspected for wear and tear, as even minor damage to a die or mandrel can translate into defects.

In-Process and Post-Process Verification

Quality is a continuous process, not a final inspection.

| Verification Stage | Technology/Method Used | Purpose |

|---|---|---|

| First Article Inspection | 3D Laser Scanning, CMM, Hard Gauges | To confirm that the machine setup and program are correct before starting a production run. |

| In-Process Checks | Operator checks with digital protractors and calipers. | To monitor for any drift or variation during the production run. |

| Final Inspection | 100% or statistical inspection using automated scanners. | To guarantee that every part shipped meets all specifications. |

By following this disciplined, technology-driven approach, we provide more than just bent pipes. We provide certainty. We ensure that the components we deliver will fit perfectly, perform flawlessly, and uphold the quality and safety of our clients' final products.

Conclusion

In summary, mastering seamless pipe bending requires a blend of advanced technology, deep material science knowledge, and rigorous process control. It's about transforming a simple pipe into a critical, high-performance component that you can rely on, ensuring both efficiency and safety in your most demanding applications.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.