Schedule 10 SS Pipe Terminology: Interpretation for Product Use

Confused by complex pipe schedules? A wrong choice can derail projects and inflate budgets. Let's clarify Schedule 10[^1] terminology so you can select with absolute confidence.

Correctly interpreting Schedule 10 (Sch 10) stainless steel pipe terminology involves understanding its key specifications—like nominal pipe size (NPS) and wall thickness. This ensures you select the right pipe for low-pressure, non-critical applications, balancing cost-efficiency with performance requirements.

As the Global Business Director at MFY, I've seen firsthand how a small misunderstanding in pipe specifications can lead to significant operational challenges. The world of stainless steel is built on precision, and terms like "Schedule 10" are not just jargon; they are critical data points that define a product's capability and its ideal role in a project. Getting this right from the start saves time, money, and ensures the integrity of your entire system. In this article, I'll walk you through the essential terminology, applications, and strategies to make you an expert in specifying Sch 10 pipes.

What is Schedule 10 Stainless Steel Pipe Terminology?

Terminology like NPS and 'schedule' can be unclear. This ambiguity often leads to ordering mistakes. Here’s a simple breakdown of the essential terms you need to know.

Schedule 10 stainless steel pipe terminology refers to the standardized system defining a pipe's dimensions, primarily its wall thickness. It signifies a thinner wall compared to higher schedules like Sch 40, making it lighter and more cost-effective for specific uses.

Let's dive deeper into the core concepts. The terminology might seem technical, but it's based on a very logical system established by standards bodies like the American National Standards Institute (ANSI)[^2]. Understanding these few key terms is the foundation for making informed decisions. It's the language engineers and suppliers use to guarantee that the pipe ordered is the pipe delivered and, most importantly, the pipe required for the job.

Key Terms Defined

The two most critical terms are Nominal Pipe Size (NPS)[^3] and Schedule (Sch). NPS is a North American standard set of sizes for pipes used for high or low pressures and temperatures. It's important to know that for NPS ⅛ to 12 inches, the NPS number is only loosely related to the actual outside diameter (OD). The Schedule number, however, is what truly defines the pipe's strength and application. It specifies the pipe's wall thickness. For a given NPS, the OD remains constant, but the wall thickness—and therefore the inside diameter—changes with the schedule number. A Sch 10 pipe will have a thinner wall than a Sch 40 pipe of the same NPS.

Schedule 10 vs. Schedule 40: A Practical Comparison

To make this clear, let's look at a common example. A misunderstanding here can be costly, so we always double-check these specs with our clients.

| NPS | Outside Diameter (OD) | Schedule | Wall Thickness | Weight per Foot |

|---|---|---|---|---|

| 2" | 2.375 in (60.3 mm) | Sch 10s | 0.109 in (2.77 mm) | 2.64 lbs (3.93 kg/m) |

| 2" | 2.375 in (60.3 mm) | Sch 40s | 0.154 in (3.91 mm) | 3.66 lbs (5.44 kg/m) |

As you can see, both pipes have the exact same outer diameter, but the Sch 40 pipe has a thicker wall and is significantly heavier. This difference is what makes Sch 10 a more economical and lighter choice, but only when the application's pressure requirements allow for it.

Where are Schedule 10 SS Pipes Most Effectively Used?

Using the wrong pipe for the job is a costly error. High-pressure systems demand thicker walls. So where does the thinner, cost-effective Schedule 10 pipe really shine?

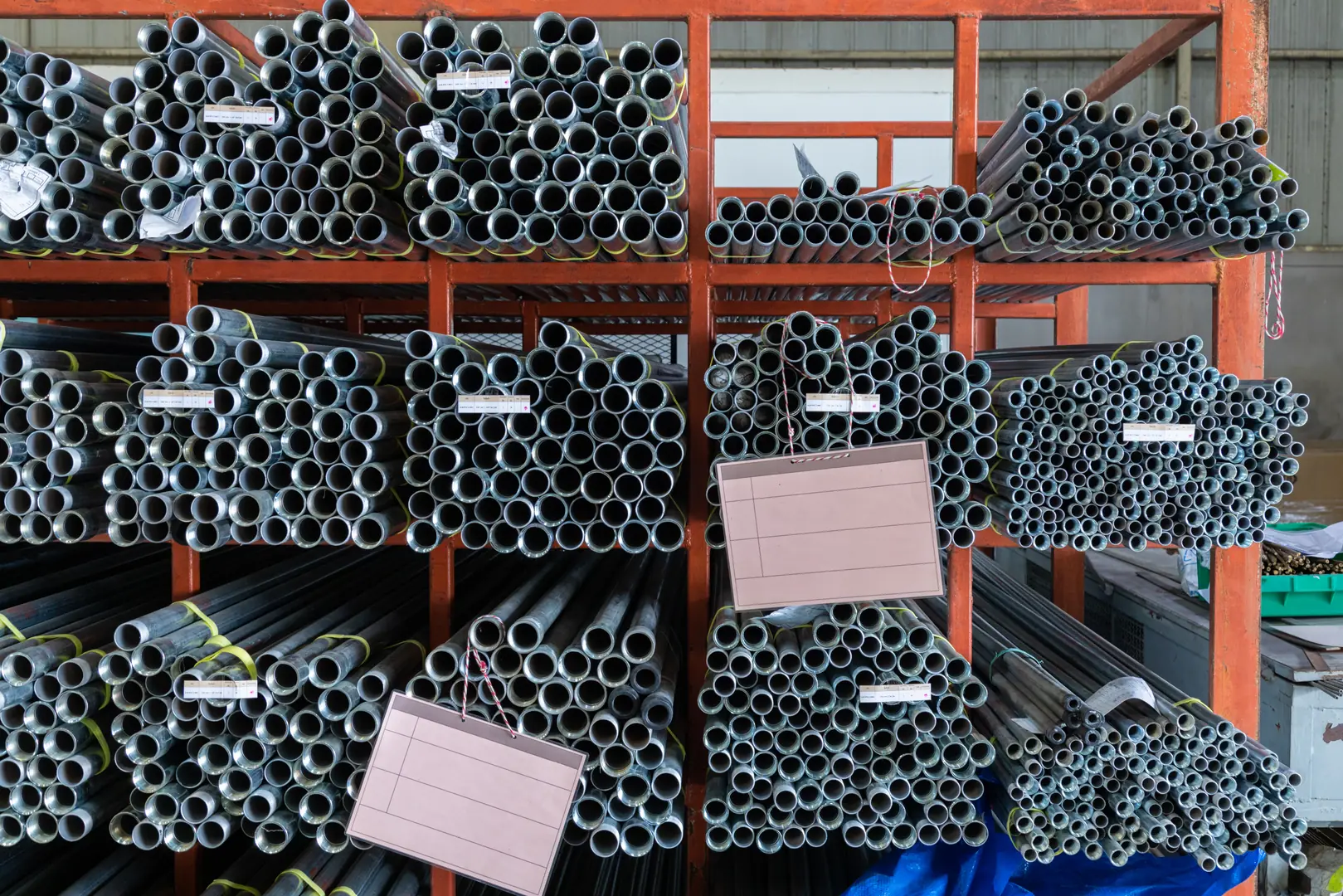

Schedule 10 stainless steel pipes are most effectively used in low-pressure and low-temperature applications. Common uses include water distribution, drainage systems, handrails, structural supports, and other non-critical fluid transport where high-pressure tolerance is not required.

The key advantage of Schedule 10 pipe is its balance of performance and economy. Because it has a thinner wall, it uses less raw material, which directly translates into lower costs and reduced weight. This makes it an excellent choice for projects where the extreme durability of a heavier-walled pipe is simply unnecessary. At MFY, we guide our clients to identify these opportunities for optimization, ensuring they aren't over-specifying and over-paying.

Low-Pressure Fluid Systems

This is the primary application for Sch 10 pipes. Think of systems like cooling water lines, drainage and vent pipes, and low-pressure chemical transfer lines. In these scenarios, the internal pressure is well within the limits of the thinner wall. I remember a client in Southeast Asia who was building a large food processing plant. They initially specified Sch 40 for all their stainless steel piping out of habit. We sat down with their engineering team and reviewed the process flow diagrams. We identified that over 60% of their piping was for low-pressure water and cleaning solutions. By switching to Sch 10 for these lines, they saved nearly 20% on their material budget and also reduced the structural load, which simplified installation.

Structural and Architectural Uses

The excellent corrosion resistance of stainless steel, combined with the lighter weight of Schedule 10, makes it a fantastic material for architectural and structural applications. This includes handrails, support frames for equipment, decorative structures, and exhaust piping. In these cases, the pipe isn't containing high pressure; its main job is to resist environmental corrosion while providing structural support. The thinner wall of Sch 10 is more than adequate for these tasks, and its lower weight makes it easier and cheaper to transport, handle, and install on-site.

What are the Common Challenges in Understanding Pipe Specifications?

Datasheets are full of numbers and acronyms. Misinterpreting them can lead to project delays or even failures. Let's pinpoint the common pitfalls so you can avoid them.

The most common challenge is confusing Nominal Pipe Size (NPS) with the actual outer diameter, especially for smaller sizes. Another major issue is assuming a lower schedule number means lower quality, rather than simply a different wall thickness for a specific application.

These challenges are not about a lack of intelligence; they stem from a system of standards that has evolved over a century and contains some historical quirks. The goal is not to memorize every chart but to understand the logic and know what to look for. A small oversight on a spec sheet can lead to a big problem on the factory floor or construction site. We've seen projects delayed for weeks because the wrong pipe was delivered, all due to a simple misunderstanding of the terminology.

The NPS vs. Outer Diameter (OD) Dilemma

This is probably the number one source of confusion. For pipes with an NPS of 12 inches and under, the NPS number does not equal the outer diameter. For example, a 1" NPS pipe has an OD of 1.315 inches. A 4" NPS pipe has an OD of 4.5 inches. It's only for NPS 14 inches and above that the NPS number finally matches the OD in inches. This is a historical convention that trips up even experienced professionals. Always refer to a standard pipe dimension chart to verify the actual OD for a given NPS. Assuming they are the same is a recipe for ordering pipes that won't fit with your existing flanges and fittings.

Equating Schedule with Quality

Another frequent mistake is thinking that a higher schedule number, like Sch 80, means "better quality" stainless steel than Sch 10. This is incorrect. The schedule number has nothing to do with the material grade or quality of the steel itself (e.g., 304L vs. 316L). It only refers to the wall thickness. A Sch 10 pipe made from 316L stainless steel has the same excellent corrosion resistance as a Sch 80 pipe made from 316L. The only difference is its ability to withstand pressure. Choosing Sch 40 when Sch 10 would suffice is not an upgrade in quality; it's an unnecessary expense.

What are the Best Strategies for Correct Interpretation and Application?

You need to be certain about your pipe choice. Guesswork is not a strategy in our industry. We use a clear, step-by-step process to ensure the perfect fit for every project.

The best strategy is a three-step process: first, clearly define your project's operational requirements (pressure, temperature, fluid). Second, consult official ANSI/ASME charts. Finally, partner with a knowledgeable supplier who can validate your choice against your application's specific needs.

This systematic approach removes ambiguity and replaces it with data-driven confidence. It’s about moving from a general idea of what you need to a precise specification that guarantees performance and optimizes cost. This is how you balance the economic and functional imperatives of any project, which is the core of efficient engineering and procurement.

Step 1: Define Application Requirements

Before you even look at a pipe chart, you must know the demands of your system. What is the maximum operating pressure? What is the temperature range? What fluid or substance will be inside the pipe? Is the external environment corrosive? Answering these questions first creates a clear performance target. Without this information, you are flying blind.

Step 2: Use Standardized Charts

Once you know your requirements, use the official industry standards as your guide. The ASME B36.19 standard covers the dimensions of stainless steel pipe. These charts are the undisputed source of truth for NPS, OD, and wall thickness for each schedule. Cross-reference your required pressure rating against the capabilities of different schedules for your chosen NPS.

Step 3: Collaborate with Your Supplier

A good supplier is more than just an order-taker; they are a partner. At MFY, our technical sales team acts as a final checkpoint for our clients. Share your application requirements with us. We can validate your selection or, based on our experience with thousands of similar projects, suggest a more optimal or cost-effective alternative. This collaborative approach is the surest way to prevent costly errors and ensure you get the perfect product for your needs.

What is the Best Technical Advice for Optimal Product Use?

You've selected the right pipe, but proper use is key. Installation and handling errors can undermine even the best material choice. Here's how to ensure long-term performance.

Our best technical advice is to focus on proper welding and joining techniques suitable for thin-walled pipe. Also, always verify material test reports (MTRs) to confirm alloy composition and ensure the pipe's corrosion resistance meets your environmental conditions.

Getting the most out of your Schedule 10 stainless steel pipe goes beyond just the initial selection. The long-term integrity and performance of your system depend heavily on how the material is handled, fabricated, and installed. A high-quality pipe can be compromised by poor practices on-site, so paying attention to these details is critical for project success and sustainability.

Welding and Fabrication

The thinner wall of Schedule 10 pipe requires more finesse during welding compared to heavier-walled pipes. The risk of "burn-through," where the welding process melts a hole through the pipe wall, is higher. For this reason, TIG (Tungsten Inert Gas) welding is often the preferred method as it offers greater control over the heat input. It's crucial that your welders are experienced with thin-walled stainless steel. Proper purging with an inert gas on the inside of the pipe is also essential to protect the weld from oxidation and maintain the material's corrosion resistance.

Material Verification and Handling

Always insist on a Material Test Report (MTR)[^4] for every batch of pipe you receive. This document is your proof of quality. It confirms the exact chemical composition of the steel, verifying that you received the grade you ordered (e.g., 304L or 316L). This is non-negotiable for ensuring the corrosion resistance your application demands. Furthermore, because the pipe wall is thinner, proper handling is important. Avoid dropping pipes or subjecting them to sharp impacts, as dents can create stress points and compromise the pipe's structural integrity, especially under pressure.

Conclusion

Understanding Schedule 10 pipe terminology is not just technical—it's strategic. By matching the right specification to the right application, you optimize costs, reduce weight, and ensure project success. It's about making informed decisions that balance performance with efficiency.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.