What are stainless steel seamless tubes?

Struggling to find tubing that withstands extreme pressure? A single weak point can compromise your entire system. Seamless tubes offer uniform strength, ensuring total reliability and operational safety.

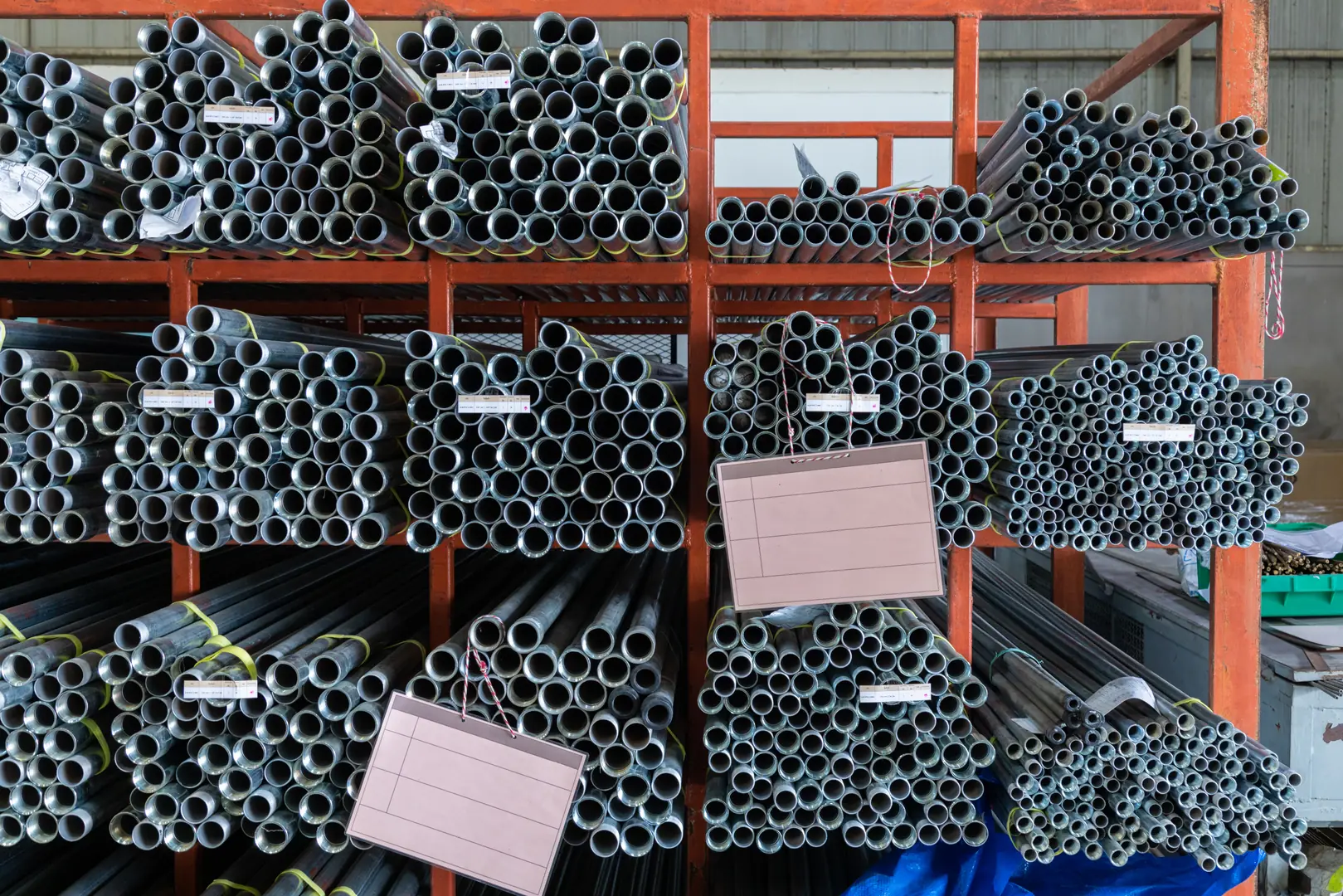

Stainless steel seamless tubes are cylindrical products made from a solid, round steel billet that is heated and pushed or pulled over a form until the steel is shaped into a hollow tube. They have no welded seams, giving them exceptional strength and corrosion resistance.

As the Global Business Director at MFY, I’ve seen firsthand how crucial the right material choice is for high-stakes industrial projects. The distinction between different types of tubing isn't just academic; it has real-world consequences for safety, efficiency, and your bottom line. Seamless tubes are often the unsung heroes in the most demanding environments. Let's explore why they are so essential and how they provide a robust foundation for modern industry.

What defines stainless steel seamless tubes?

Defining a seamless tube seems simple, right? But its manufacturing process is what truly sets it apart. It’s a single, solid piece of steel, formed without any joints.

A stainless steel seamless tube is defined by its manufacturing method: it is produced from a solid piece of steel with no welding or seams. This monolithic structure gives it a uniform grain, immense strength, and consistent dimensions throughout its length.

The magic of a seamless tube lies in its origin story. Unlike other pipes that start as a flat strip and are welded together, a seamless tube begins life as a solid cylindrical bar of steel, known as a billet. This process ensures the final product is a single, continuous piece of metal, which is fundamental to its performance characteristics. From my experience overseeing supply chains, this manufacturing integrity is precisely what engineers and project managers look for when failure is not an option. It's a testament to precision engineering, where the absence of a feature—the weld seam[^1]—is its greatest strength.

The Solid Billet Foundation

Everything starts with a high-quality, solid steel billet. The chemical composition of this billet determines the properties of the final tube, such as its corrosion resistance and strength at high temperatures. At MFY, we place immense emphasis on the quality of our raw materials because we know that the integrity of the final product depends entirely on the quality of its foundation. A flawless billet is the first step toward a flawless tube.

The Piercing and Extrusion Process

The billet is heated to extreme temperatures, making it malleable. It is then pierced through the center with a mandrel. This is the critical step that creates the hollow shape. The pierced billet is then rolled and stretched to achieve the desired wall thickness and diameter. This hot-working process refines the steel's grain structure, resulting in a tube that is incredibly strong and uniform. This uniformity is vital for applications involving high internal or external pressure, as it eliminates the weak points that can be present in other types of tubing.

How do seamless tubes differ from welded tubes?

Choosing between seamless and welded tubes can be confusing. Making the wrong choice can lead to system failure and costly downtime. The key difference is the weld seam itself.

The primary difference is that seamless tubes are extruded from a single billet of steel, making them weld-free. Welded tubes are made from a steel strip that is rolled and welded longitudinally, creating a seam that can be a potential point of weakness.

This structural difference is the most important factor to consider when selecting tubing for your application. I remember a client in the chemical processing industry who faced a costly system failure. The root cause was a corroded weld seam in a welded pipe that couldn't handle the aggressive chemicals being transported. They switched to our stainless steel seamless tubes, and the problem was completely eliminated. The absence of a seam not only removes a physical weak point but also creates a more uniform surface that is less susceptible to preferential corrosion. This single distinction impacts everything from pressure ratings to long-term reliability.

A Head-to-Head Comparison

To make the choice clearer, let's break down the key differences in a simple table. This is the kind of analysis we walk our clients through at MFY to ensure they get the right product for their specific needs.

| Характеристика | Stainless Steel Seamless Tube | Stainless Steel Welded Tube |

|---|---|---|

| Производство | Extruded from a solid billet | Rolled from a flat strip and welded |

| Структурная целостность | Uniform and monolithic (no seams) | Contains a longitudinal weld seam |

| Номинальное давление | Excellent; can handle very high pressures | Good, but the seam is a potential weak point |

| Устойчивость к коррозии | Superior; uniform resistance | The seam can be prone to localized corrosion |

| Толщина стенок | Very uniform and concentric | Can have slight variations near the weld |

| Стоимость | Generally higher due to complex process | More cost-effective for lower-pressure uses |

As you can see, while welded tubes are suitable for many applications, seamless tubes are the undisputed choice for critical systems where strength, safety, and reliability are paramount.

What are the key benefits of using stainless steel seamless tubes?

You need components that won't fail under intense pressure. A single weak point can halt your entire operation. Seamless tubes offer unparalleled strength, durability, and peace of mind.

The key benefits are superior pressure handling, enhanced corrosion resistance due to a uniform surface, a completely homogenous structure for reliability, and the ability to withstand extreme temperatures and harsh environments without the risk of seam-related failure.

When we talk about benefits, we're really talking about value. For our clients in sectors like power generation or oil and gas, the value of a seamless tube isn't just in its physical properties, but in the operational efficiency and safety it guarantees. Choosing a seamless tube is an investment in long-term performance. It means fewer inspections, lower maintenance costs, and a significantly reduced risk of catastrophic failure. This is where the initial higher cost pays for itself many times over during the lifespan of a project.

Unmatched Pressure and Temperature Resistance

Because there is no weld seam, a seamless tube can withstand higher pressures, both internal and external. The steel's grain structure is consistent all the way around, meaning there are no hidden weak spots. This makes it the only viable option for high-pressure hydraulic systems, boilers, and compressed gas transportation, where safety and performance are non-negotiable.

Superior Corrosion Resistance

The weld seam in a welded tube can sometimes have a slightly different composition or microstructure than the parent metal. This can create a galvanic cell, leading to accelerated corrosion along the seam. A seamless tube, being completely uniform, does not have this vulnerability. It corrodes at a much more predictable and even rate, making it ideal for transporting corrosive fluids in chemical plants.

A Catalyst for Green Technology

A unique perspective we're seeing emerge is the role of seamless tubes in sustainability. Their incredible durability means a longer service life for the infrastructure they are part of. A longer lifespan means less frequent replacement, which in turn reduces the consumption of raw materials and the energy required for manufacturing and installation. By building things to last with robust materials like seamless tubes, we are contributing to a more sustainable industrial future—a principle we strongly support at MFY.

In which industries are stainless steel seamless tubes commonly used?

Specifying the right tube for your project is crucial. Using mismatched materials is not just inefficient; it can be a serious safety hazard. Seamless tubes are the industry standard where it matters most.

Stainless steel seamless tubes are indispensable in industries like oil and gas (for drilling and transport), chemical and petrochemical processing, power generation (in boilers and heat exchangers), and pharmaceuticals, where high purity and structural integrity are critical.

The common thread across these industries is the need for absolute reliability. In my role, I work with leaders from these sectors, and they all share the same concern: managing risk. Whether it's the risk of an environmental incident, a production shutdown, or a safety breach, the material choices they make are on the front line of their risk mitigation strategy. Stainless steel seamless tubes are specified in their most critical systems because they offer a level of assurance that other materials simply cannot match. They are a foundational component for safe and efficient operations.

Oil & Gas Exploration

In the oil and gas sector, seamless tubes are used for downhole applications, where they must withstand immense pressure and corrosive environments deep underground. They are also used in pipelines and refinery systems to transport high-pressure fluids and gases safely.

Chemical and Petrochemical Processing

Chemical plants rely on seamless tubes to handle highly corrosive acids, bases, and other chemicals at various temperatures and pressures. The uniform corrosion resistance of seamless tubing is essential to prevent leaks and ensure the purity of the product.

Power Generation

In both fossil fuel and nuclear power plants, seamless tubes are critical components in boilers, superheaters, and heat exchangers. They must endure constant high temperatures and pressures to generate steam efficiently and safely, making their structural integrity a core requirement for power generation.

What are the recommendations for selecting quality stainless steel seamless tubes?

Sourcing quality seamless tubes can be a challenge. Poor quality materials can lead to project delays, budget overruns, and significant operational risks. The solution is to focus on verification and partnership.

To select quality seamless tubes, verify the correct material grade (e.g., 304L, 316L), insist on industry certifications like ASTM/ASME, and partner with a reputable supplier who provides comprehensive documentation and has a proven track record of quality control.

Selecting the right tube goes beyond just looking at a spec sheet. It's about ensuring that what you order is what you get, and that it will perform as expected for years to come. I've seen too many projects derailed by materials that didn't meet the required standards. That's why building a relationship with a trusted supplier is so important. A good partner doesn't just sell you a product; they provide the assurance and documentation you need to proceed with confidence.

Understanding Material Grades

The grade of stainless steel determines its specific properties. For example, Grade 304 is a versatile, general-purpose choice, while Grade 316L offers superior corrosion resistance, especially against chlorides, making it ideal for marine or chemical applications. Ensure the grade you select matches the demands of your environment.

The Importance of Certifications

Certifications from bodies like ASTM (American Society for Testing and Materials) or ASME (American Society of Mechanical Engineers) are not just formalities. They are a guarantee that the tube has been manufactured and tested according to rigorous international standards. Always request a Material Test Certificate (MTC)[^2] for every batch you purchase.

Choosing the Right Supplier

Your supplier is your partner in quality. At MFY, we see our role as more than just a provider of stainless steel. We are a part of our clients' supply chain, and we take that responsibility seriously. A reliable supplier will have a robust quality management system, provide full traceability for their products, and offer expert guidance to help you select the perfect material for your needs. This partnership is the final, and perhaps most crucial, step in ensuring you get the quality you deserve.

Заключение

Stainless steel seamless tubes are more than just a component; they are a strategic asset for any critical application. Their weld-free construction provides unmatched strength, corrosion resistance, and reliability, making them the superior choice for high-pressure and high-temperature environments. They are an investment in safety and efficiency.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.