Precision Tube Bending: Technical Data & Custom Die Services

Struggling with inconsistent bends and material waste? These issues delay projects and inflate costs, undermining your competitive edge. Precision tube bending with custom dies delivers the accuracy you need.

Precision tube bending is a specialized manufacturing process using advanced technical data and custom die services to create highly accurate, repeatable bends in tubing. It is essential for industries like aerospace and automotive, ensuring components meet strict specifications, reduce waste, and enhance structural integrity.

In my years as Global Business Director at MFY, I've seen how manufacturing has evolved. The demand for lighter, stronger, and more complex components has never been higher. Standard fabrication methods just can't keep up. This is where precision tube bending[^1] becomes not just an advantage, but a necessity. It’s the difference between a component that simply fits and one that performs flawlessly under pressure. Let's explore how this technology, especially when paired with custom tooling[^2], can transform your production process.

Why is Precision Tube Bending Foundational to Modern Manufacturing?

Complex product designs demand more than basic fabrication. Without the exacting standards of precision bending, the performance, safety, and reliability of the final product are seriously compromised.

Precision tube bending is foundational because it enables the creation of complex, lightweight, and high-strength components essential for advanced industries. It ensures every part conforms to tight tolerances, which is critical for system performance in sectors like aerospace, automotive, and medical devices.

The journey of tube bending from a manual art to a data-driven science is a story of industrial evolution. In the past, achieving a good bend was reliant on the skill of an experienced operator. Today, while craftsmanship is still vital, it's augmented by technology that delivers a level of precision that was once unimaginable. This shift is driven by the relentless demands of modern manufacturing. Industries are pushing the limits of design, requiring intricate geometries for everything from fuel lines in a jet engine to exhaust systems in a high-performance car. These applications require absolute repeatability and conformity to specifications, where even a minor deviation can have significant consequences. At MFY, we see this every day. Our clients aren't just buying a bent tube; they are buying the assurance of performance.

The Shift to Data-Driven Accuracy

The core of modern precision bending is the integration of digital control and feedback. Advanced computational models allow us to simulate the bending process before a single piece of material is touched. This predictive capability is a game-changer, allowing us to account for material properties and potential issues like springback[^3]. It reduces the costly and time-consuming trial-and-error phase, leading to more efficient production cycles and less waste. This is particularly vital for projects involving expensive alloys.

Impact on Key Industries

Consider the aerospace sector. Every gram of weight matters, and structural integrity is non-negotiable. Precision bending allows engineers to design fluid and air systems that are both lightweight and incredibly robust. In the automotive world, it's about optimizing performance and space. A precisely bent exhaust system can improve engine efficiency, while custom-bent chassis components can enhance vehicle safety and handling. This is why we've invested so heavily in our technology and the skills of our team—to serve as an indispensable partner in these demanding ecosystems.

What are the Current Techniques and Technologies in Tube Bending?

Keeping up with rapidly advancing manufacturing technology is a constant challenge. Relying on outdated methods hurts your efficiency, quality, and ultimately, your bottom line in a competitive market.

Current leading techniques include CNC (Computer Numerical Control) rotary draw bending, laser measurement systems for real-time verification, and advanced simulation software. These technologies work together to provide unparalleled control, accuracy, and repeatability in the bending process.

The technology behind tube bending is what separates standard work from true precision manufacturing. It’s not just about the machine; it’s about the entire digital ecosystem that supports the process. I remember a client in the automotive sector who was struggling with high rejection rates for a complex exhaust component. Their process was inconsistent. By helping them integrate a system with simulation software and in-process laser measurement, we helped them virtually eliminate defects and cut their prototyping time in half. It was a powerful demonstration of how the right technology transforms an operation.

CNC Bending and Control

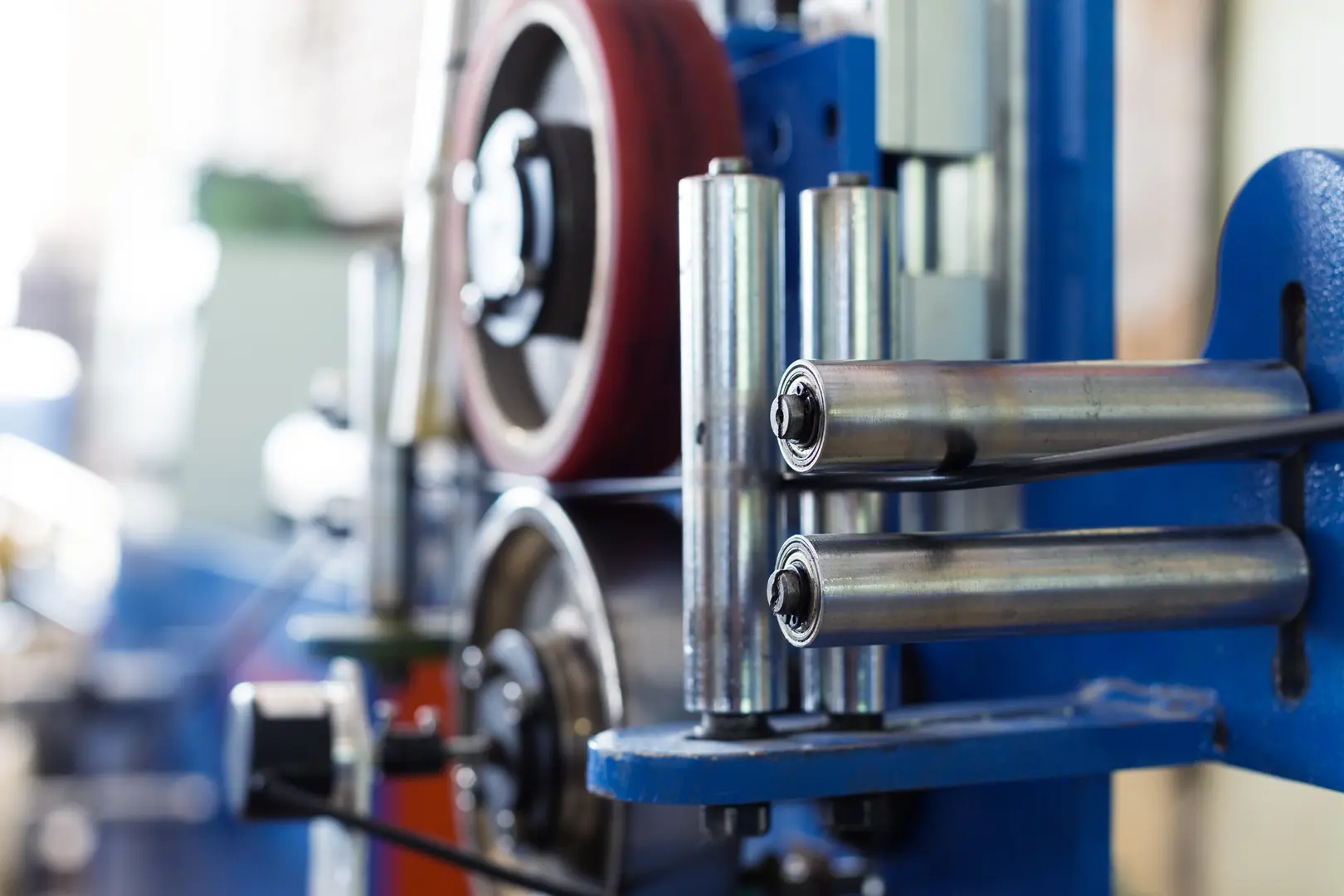

At the heart of modern precision is the CNC bending machine[^4]. These machines translate a digital design file into a series of precise mechanical movements. Key components like the bend die, clamp die, and pressure die are all controlled by the computer to fractions of a millimeter and degree. This allows for multi-axis bending and the creation of highly complex shapes in a single, continuous process, ensuring perfect consistency from the first part to the ten-thousandth.

The Role of Simulation and Measurement

Before we even load a tube into the machine, simulation software plays a critical role. It allows us to predict how a specific material will behave during bending. We can anticipate and correct for:

- Springback: The tendency of the material to partially return to its original shape after bending.

- Wall Thinning: The stretching and thinning of the outer wall of the bend.

- Wrinkling: The compression and buckling of the inner wall of the bend.

By modeling these factors, we can design the tooling and program the machine to compensate perfectly. Then, during the production run, non-contact laser measurement systems can scan the part in real-time to verify that every dimension is within the specified tolerance, providing a closed-loop quality control system.

What are the Main Challenges in Achieving Precision Tube Bending?

Achieving a perfect bend is much harder than it looks. Material inconsistencies, springback, and wall thinning are common issues that can ruin expensive materials and cause production delays.

The primary challenges are managing material springback, preventing wall thinning on the outer radius and wrinkling on the inner radius, and avoiding ovality (distortion of the tube's cross-section). Each of these requires precise control over tooling, material, and machine parameters.

Overcoming these challenges is where expertise truly comes into play. Every material, and even different batches of the same material, can behave differently. Stainless steel, for example, has a higher degree of springback than mild steel. An experienced team, backed by robust data, knows how to anticipate and manage these variables. It’s a constant process of analysis and adjustment. You can't just set the machine and walk away; you have to understand the physics of what's happening to the material at a microscopic level. This deep understanding is what prevents costly errors and ensures the final product has the structural integrity required for its application.

Understanding the Core Problems

To achieve precision, we must master the forces at play during the bending process. The material on the outside of the bend is under tension and wants to stretch, while the material on the inside is under compression and wants to buckle.

| Вызов | Описание | Common Cause |

|---|---|---|

| Springback | The partial unbending of the tube after the bending force is removed. | The material's natural elasticity. Varies by material type, hardness, and wall thickness. |

| Wall Thinning | The stretching and reduction in wall thickness on the outside of the bend. | Excessive stretching force without proper support from a mandrel. |

| Wrinkling | The formation of ripples or buckles on the inside radius of the bend. | Insufficient support from a wiper die, allowing the compressed material to deform. |

| Ovality | The distortion of the tube's circular cross-section into an oval shape at the bend. | Inadequate internal support from the mandrel during the bending process. |

Managing these issues requires a holistic approach, starting from the initial design and carrying through to the final quality check. It's a blend of engineering science and hands-on experience.

How Can You Overcome These Precision Bending Challenges?

These challenges can seem daunting, and ignoring them leads to high scrap rates, production failures, and compromised product quality, directly impacting your profitability and reputation.

Overcoming these challenges requires a multi-faceted strategy: utilizing advanced simulation software to predict material behavior, selecting the right custom tooling like mandrels and wiper dies, precise machine calibration, and rigorous material characterization before production begins.

The solution to precision bending challenges isn't a single magic bullet, but a systematic process of control. It starts with knowing your material inside and out. At MFY, we don't just look at a material spec sheet; we often conduct our own tests to understand the specific properties of the batch we are working with. This data feeds directly into our simulation software, allowing us to create a highly accurate digital twin of the bending process. This proactive approach allows us to design the process to avoid problems, rather than just reacting to them. It’s about building quality into every step.

Intelligent Tooling and Process Control

The right tool for the job is critical. A high-quality, properly designed mandrel is essential for providing internal support to prevent ovality and collapse. A wiper die, set with extreme precision, prevents wrinkling on the inside of the bend. The material and surface finish of these tools are also crucial to prevent galling and ensure a smooth, clean bend.

A Systematic Approach

Here are the key strategies we employ:

- Material Characterization: We analyze the tensile strength, elongation, and hardness of the specific tube material to accurately predict its behavior, especially springback.

- Advanced Simulation: We use software to model the entire bending process, allowing us to optimize machine parameters and tool design before any physical work starts. This drastically reduces setup time and material waste.

- Custom Tooling Design: Based on the simulation, we select or manufacture custom dies, mandrels, and wipers that are perfectly matched to the tube's diameter, wall thickness, material, and bend radius.

- Process Monitoring: During production, we use real-time feedback systems, including laser scanners and force sensors, to ensure the machine is performing exactly as programmed and to make micro-adjustments as needed.

This combination of preparation, custom tooling, and real-time control is how we consistently deliver parts that meet the most stringent specifications.

What Technical Recommendations Matter for Custom Die Services?

Using off-the-shelf dies for a complex or high-tolerance job is a recipe for failure. The wrong die can damage expensive tubing, cause unacceptable defects, and lead to inconsistent results.

For custom die services, key recommendations include selecting the correct die material (e.g., tool steel) for durability, ensuring the die's geometry perfectly matches the tube's specifications, and utilizing a high-quality surface finish to reduce friction and prevent material galling.

Custom dies are the heart of precision tube bending. They are the interface between the machine and the material, and their quality directly determines the quality of the final product. This is an area where there can be no compromise. Investing in a properly engineered custom die set is one of the most important decisions in setting up a high-precision bending operation. It's not just a piece of metal; it's a highly engineered tool designed to control material flow under immense pressure. We've built our reputation at MFY on our ability to design and produce custom tooling that solves our clients' most complex bending challenges, positioning us as a true partner in their manufacturing success.

Key Components of a Custom Die Set

A complete die set is more than just the main bend die. It's a system of components working in concert.

| Component | Function | Key Design Consideration |

|---|---|---|

| Bend Die | Forms the radius of the bend. | The radius must be precise, and the tube groove must match the tube's outer diameter perfectly. |

| Clamp Die | Grips the straight section of the tube to hold it against the bend die. | Must provide a firm grip without marking or deforming the tube. Length is critical. |

| Pressure Die | Applies pressure to the tube as it's drawn around the bend die to support it. | Must apply consistent force along the point of tangency to prevent deformation. |

| Mandrel | Supports the inside of the tube during the bend to prevent collapse and ovality. | Design (e.g., plug, ball mandrel) and fit are critical, based on wall thickness and bend radius. |

| Wiper Die | Supports the inside radius of the bend to prevent wrinkling or buckling. | The tip must be precisely angled and positioned at the point of tangency. |

When you partner with a service provider, ensure they have a deep understanding of how these components interact. They should ask detailed questions about your material, bend specifications, and end-use application to engineer a tooling solution that is truly tailored to your needs.

Заключение

Precision tube bending, powered by advanced technology and expertly engineered custom dies, is no longer a niche capability but a core requirement for competitive manufacturing. It’s the key to producing the complex, high-performance components that today's advanced industries demand, directly impacting your efficiency, quality, and profitability.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.