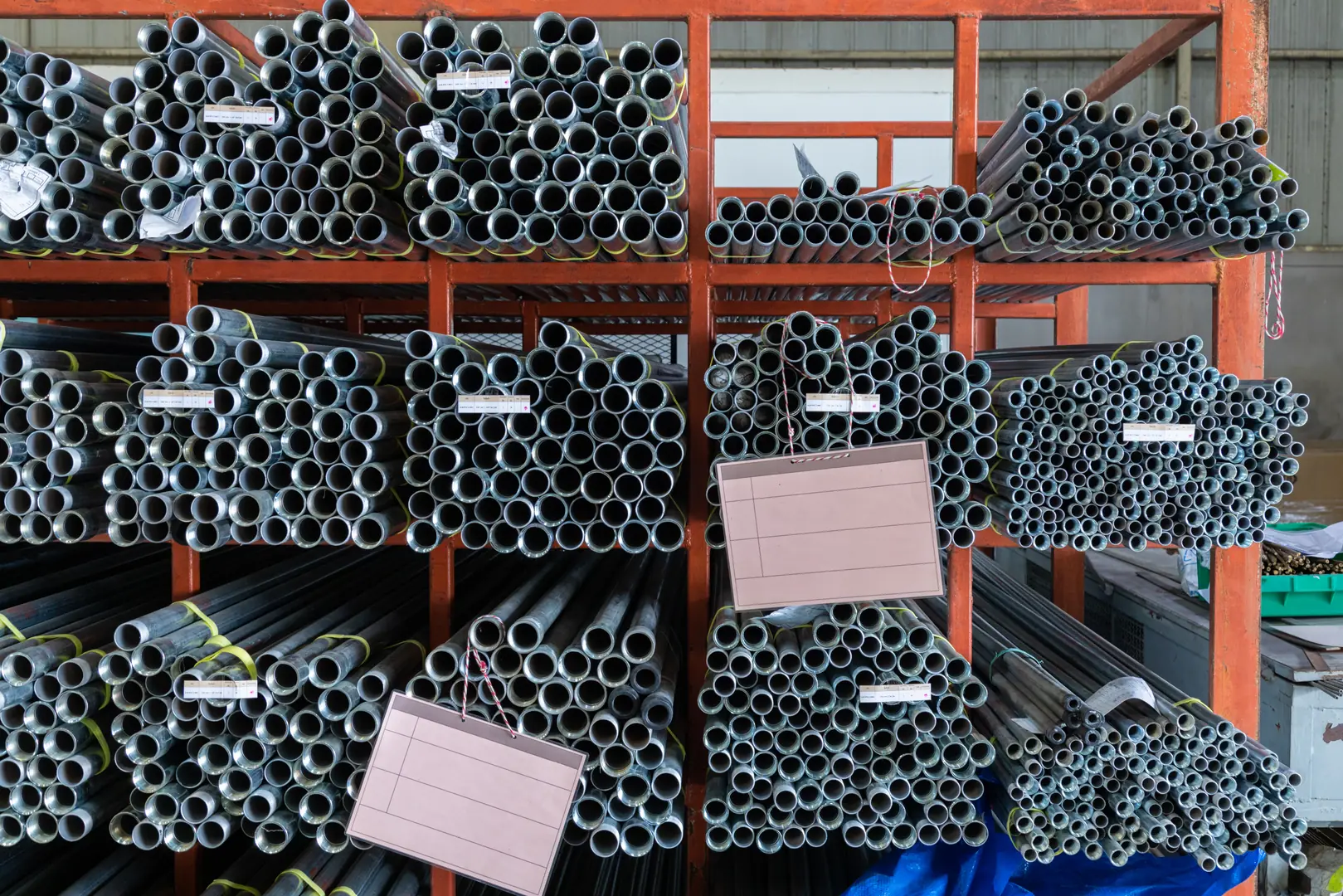

China Wholesale: 304 SS Tubing for Global Manufacturers & Suppliers

Sourcing quality 304 SS tubing is a major challenge. Global disruptions add risk and cost. China's mature wholesale market offers the stability and value your business needs.

China's wholesale 304 stainless steel tubing market is crucial for global manufacturers due to its immense production capacity, competitive pricing, and an increasingly agile, digitally integrated supply chain. This combination provides a reliable and cost-effective solution for securing high-quality materials amid global uncertainties.

As the Global Business Director at MFY, I see these dynamics play out every day with our partners across the globe. The strategic importance of China's stainless steel industry isn't just about volume anymore; it's about resilience, innovation, and partnership. Let's break down why China has become so central to this industry and how you can navigate it effectively to build a stronger, more competitive supply chain.

What is the significance of China in the global 304 stainless steel tubing market?

Need reliable tubing but face high costs? Market volatility makes planning difficult. China's market offers unparalleled scale and competitive pricing, ensuring your project's viability and success.

China's significance lies in its position as the world's largest producer and exporter of stainless steel. Its vast manufacturing infrastructure, economies of scale, and integrated supply chain provide global buyers with unmatched access to high-volume, cost-effective 304 SS tubing.

When we look deeper, China's role extends far beyond simple production numbers. It's the engine of the global stainless steel supply chain. The sheer scale of operations here allows for cost efficiencies that are difficult to replicate elsewhere. This isn't just about cheaper labor; it's about a highly optimized ecosystem that covers everything from raw material processing to advanced manufacturing and global logistics. At MFY, we leverage this ecosystem to provide our partners with not just a product, but a complete supply chain solution. The versatility of 304 stainless steel means it's in constant demand across critical sectors. I've worked with clients in the automotive industry who need precision tubing for exhaust systems, construction firms requiring durable structural components, and food processing companies that depend on hygienic, corrosion-resistant materials. China's ability to cater to all these diverse needs, at scale, makes it an indispensable hub. This concentration of production and expertise creates a competitive environment that drives innovation and keeps prices sharp, directly benefiting global manufacturers who source from here.

Key Industrial Applications Driving Demand

| Industry Sector | Primary Use for 304 SS Tubing | Key Requirement |

|---|---|---|

| Automotive | Exhaust systems, fuel lines | High-temperature resistance, formability |

| Construction | Handrails, structural supports, decorative elements | Corrosion resistance, aesthetic finish |

| Food & Beverage | Processing equipment, piping, storage tanks | Hygienic properties, ease of cleaning |

| Chemical | Fluid transport, processing vessels | Excellent corrosion resistance |

How does the current supply chain of 304 SS tubing operate in China?

Navigating a foreign supply chain feels opaque. You worry about delays and lack of control. China's modern supply chain is more integrated and transparent than ever before.

China's 304 SS tubing supply chain is a highly integrated ecosystem, moving from raw material sourcing and large-scale production to sophisticated logistics and digital trade platforms. This model ensures efficiency, reduces lead times, and offers end-to-end visibility for global partners.

The modern Chinese supply chain is a far cry from what it was a decade ago. It’s a sophisticated and increasingly digital network. It all starts with the raw materials—nickel and chromium—which are either sourced domestically or imported efficiently. These are fed into massive, state-of-the-art steel mills that produce the foundational stainless steel coils. From there, these coils are distributed to specialized manufacturers who focus on producing high-quality tubing. This is where companies like MFY come in. We bridge the gap between these powerful production facilities and the global market. We don't just trade; we manage the entire process. This includes stringent quality control checks at the factory, handling complex export documentation, and managing multimodal logistics[^1] to ensure timely delivery to our clients' doors, whether they are in Europe, South America, or Southeast Asia. Digital innovation is the glue holding this all together. From online ordering platforms to real-time shipment tracking, technology has brought a new level of transparency and efficiency, allowing our clients to have confidence and visibility throughout the entire sourcing process.

The MFY Integrated Supply Chain Model

| Stage | Описание | Key Advantage |

|---|---|---|

| 1. Raw Material | Sourcing of nickel, chromium, and scrap steel. | Access to stable, high-volume inputs. |

| 2. Production | Conversion into 304 SS coils and then into tubing. | Economies of scale, advanced manufacturing. |

| 3. Quality Control | MFY on-site inspection and third-party verification. | Ensures compliance with international standards. |

| 4. Logistics & Export | Management of packaging, customs, and shipping. | Streamlined, reliable, and cost-effective delivery. |

| 5. Digital Interface | Online portals for order management and tracking. | Transparency and ease of business. |

What are the challenges faced by global manufacturers when sourcing from China?

Sourcing from China seems promising but risky. You fear quality issues, communication barriers, and logistical nightmares. Understanding these challenges is the first step to mitigating them effectively.

Global manufacturers face challenges including navigating quality control inconsistencies between suppliers, overcoming language and cultural barriers, managing complex logistics and customs, and dealing with potential payment and intellectual property risks. Finding a trustworthy partner is key to overcoming these hurdles.

While the opportunities are immense, it's naive to think sourcing from China is without its challenges. I've spent my career helping international partners navigate this landscape, and I've seen where things can go wrong. The most common issue is inconsistent quality. A sample may look perfect, but the bulk order that arrives months later doesn't meet the same standard. This often happens when dealing with smaller, less-vetted trading companies. Communication is another significant hurdle. It's not just about language; it's about understanding business culture and expectations. A simple "yes" might mean "I understand," not "I agree and will do it." Then there are the logistics. I remember a client in Germany whose shipment was delayed for weeks due to incorrect customs paperwork filed by their previous supplier. It was a costly lesson for them. These issues—quality, communication, and logistics—are precisely why choosing the right partner is not just important, it's fundamental to your success. A good partner acts as your team on the ground, preemptively solving these problems.

Common Sourcing Pitfalls

- Quality Fade: The quality of products declines over time after the initial orders meet specifications.

- Communication Gaps: Misunderstandings due to language and cultural differences lead to incorrect orders.

- Logistical Hurdles: Inexperienced handling of customs, shipping, and documentation causes costly delays.

- Supplier Reliability: Working with a supplier who disappears or cannot scale with your demand.

What strategies can manufacturers adopt to overcome sourcing challenges?

Facing sourcing hurdles can be daunting. You might feel stuck or exposed to unacceptable risk. The right strategies and partnerships can transform these challenges into competitive advantages.

Manufacturers can overcome sourcing challenges by partnering with an established, integrated supplier like MFY. Key strategies include conducting thorough due diligence, establishing clear quality specifications, leveraging local expertise for logistics, and building long-term, trust-based relationships to ensure reliability.

s Complex network of shiny stainless steel pipes used in industrial manufacturing processes.](https://chnmfy.com/wp-content/uploads/2025/08/industrial-stainless-steel-pipes-3.webp)

The solution to overcoming sourcing challenges isn't to avoid the market; it's to engage with it intelligently. The single most effective strategy is to align with a partner who has a deep, integrated presence in the industry. This moves you from being a transactional buyer to a strategic partner. At MFY, our entire model is built on this principle. We are not just a middleman; we are part of a diversified group with deep roots in production and supply chain management. This allows us to provide a level of oversight and reliability that a simple trading agent cannot. You should insist on transparency. Ask for factory audits, request material test certificates for every batch, and establish a clear Quality Agreement. A good partner will welcome this scrutiny. Furthermore, leverage your partner's logistical expertise. An experienced team can navigate the complexities of international shipping and customs clearance, turning a potential headache into a seamless process. Ultimately, it’s about building a relationship. When your supplier understands your business and your goals, they become an extension of your own team.

From Risk to Reward: A Strategic Comparison

| Common Pitfall | The MFY Solution (Effective Strategy) |

|---|---|

| Vetting unknown suppliers online. | Partnering with an established group with a proven track record and transparent operations. |

| Vague quality requirements. | Establishing clear technical specifications and a binding Quality Agreement from the start. |

| Managing logistics independently. | Leveraging an integrated logistics team that handles everything from port to your door. |

| Transactional, short-term orders. | Building a long-term relationship for consistent quality, better service, and strategic advice. |

What technical considerations should be taken when choosing 304 SS tubing suppliers in China?

Not all 304 tubing is the same. You need specific grades and finishes for your application. Choosing the wrong supplier can lead to product failure and costly rework.

Key technical considerations include verifying the supplier's material certifications (e.g., ASTM, EN), confirming their manufacturing capabilities for specific dimensions and tolerances, assessing their quality control processes, and ensuring they can provide the required surface finishes (e.g., polished, brushed).

This is where the details truly matter. For engineers and procurement managers, getting the technical specifications right is non-negotiable. The term "304 stainless steel" is a category, not a single product. Your application demands precision. First, always demand Сертификаты испытаний мельниц (MTC)[^2] that verify the chemical composition of the steel, ensuring it meets international standards like ASTM A249/A269[^3] or equivalent EN standards. This is your primary guarantee against substandard materials. Second, scrutinize the supplier's manufacturing capabilities. Can they consistently produce tubing with the outer diameter (OD), wall thickness, and length you require, all within your specified tolerances? Ask for their tolerance range. Third, discuss their quality control procedures. Do they perform eddy current testing[^4] on the weld seam? What about hydrostatic or pneumatic pressure tests to ensure integrity? Finally, specify the surface finish. Whether you need a standard mill finish, a brushed finish for architectural use, or a highly polished finish for hygienic applications, a capable supplier must be able to deliver it consistently.

Critical Technical Checklist for 304 SS Tubing

| Technical Specification | Why It Matters | What to Ask a Supplier |

|---|---|---|

| Chemical Composition | Ensures corrosion resistance and mechanical properties. | "Can you provide a Mill Test Certificate (MTC) for every batch?" |

| Dimensional Tolerances | Guarantees the tube will fit and function correctly in assembly. | "What are your standard tolerances for OD, wall thickness, and straightness?" |

| Weld Seam Integrity | The weakest point of a welded tube; failure can be catastrophic. | "What NDT methods, like eddy current testing, do you perform on the weld?" |

| Шероховатость поверхности (Ra) | Critical for aesthetics, cleanability, and flow characteristics. | "Can you achieve and consistently deliver our required Ra surface finish?" |

Заключение

Sourcing 304 SS tubing from China offers significant advantages in cost and scale. By understanding the market, choosing the right integrated partner, and focusing on technical due diligence, you can build a resilient and competitive supply chain for the future.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.