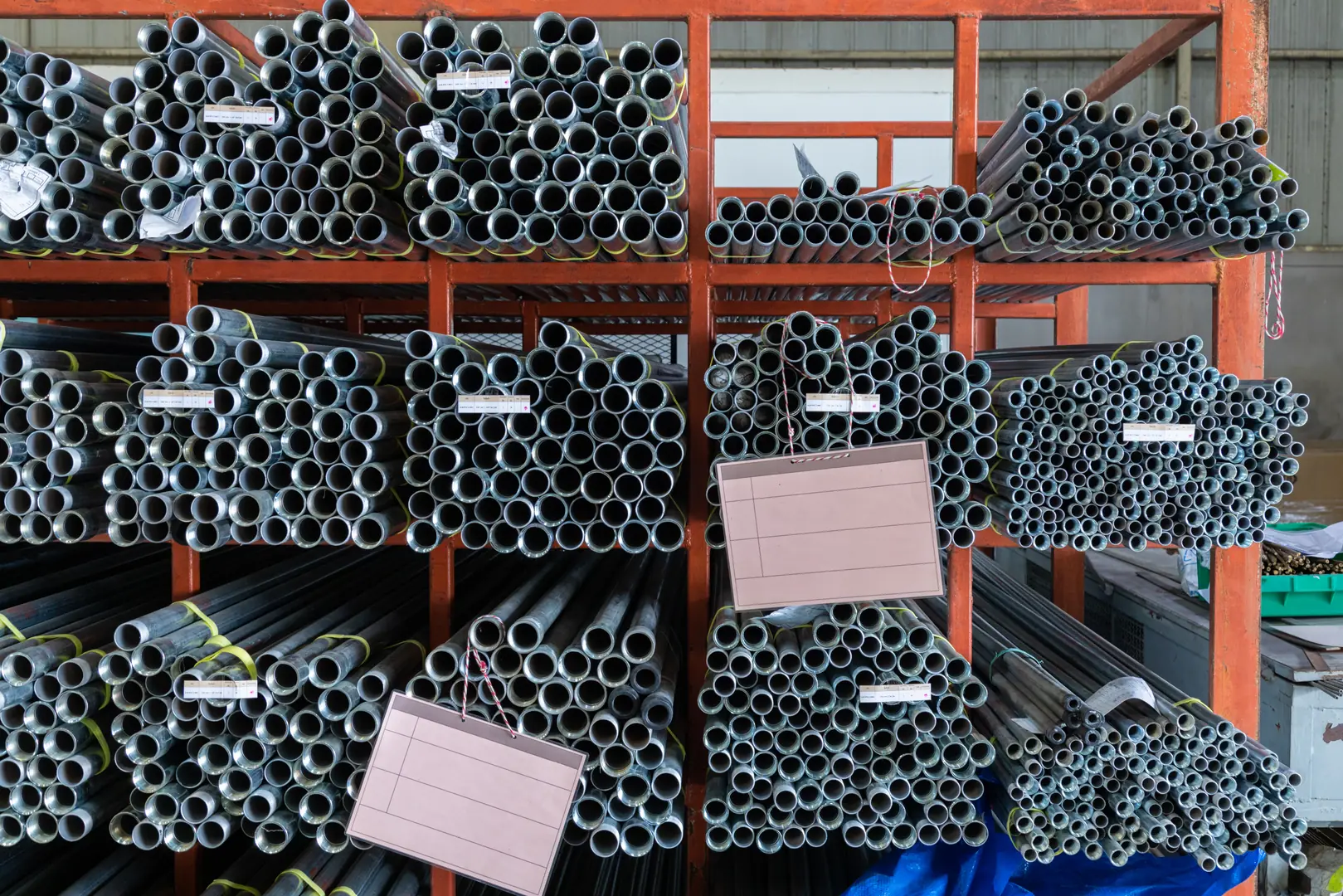

China’s Leading 304 SS Pipe Manufacturer: Factory Bulk Pricing & Global Export Logistics

Sourcing reliable 304 SS pipes is tough. Fluctuating prices and complex logistics create risk. MFY offers stability through integrated manufacturing and direct factory pricing, ensuring supply chain security.

China’s leading 304 stainless steel pipe manufacturers leverage economies of scale, advanced production technology, and integrated logistics networks. This allows them to offer competitive factory bulk pricing and streamlined global export solutions, providing a significant advantage to international buyers.

As the Global Business Director at MFY, I've seen firsthand how the global perception of Chinese manufacturing has evolved. It's no longer just about volume; it's about value, precision, and partnership. The ability to deliver high-quality 304 stainless steel pipes at competitive bulk prices is only half the story. The other half is ensuring those products reach our partners across the globe efficiently and reliably. Let's explore how we make this happen, turning potential supply chain headaches into a competitive advantage for your business.

What Defines China’s 304 SS Pipe Manufacturing Industry Today?

Understanding the market is difficult. It seems vast and complex. We see it as a dynamic hub of scale, quality, and innovation, driven by deeply integrated supply chains.

China's 304 SS pipe industry is defined by its massive production capacity, strict adherence to international quality standards, and a highly integrated supply chain. This ecosystem ensures consistent quality, cost-efficiency, and rapid scalability for global projects.

When international buyers think of China's steel industry, the first word that often comes to mind is "scale." And they're right—the sheer volume is staggering. But focusing only on scale misses the fundamental shift that has occurred over the last decade. The industry has pivoted from a purely volume-driven model to one centered on value, quality, and technological advancement. This transformation is the real story. At MFY, we are part of this evolution, operating within an ecosystem that allows us to deliver not just products, but comprehensive solutions.

From Volume to Value

The narrative has changed. Today, leading manufacturers are heavily invested in state-of-the-art production lines, precision engineering, and rigorous quality control protocols that meet or exceed international standards like ASTM, EN, and JIS[^1]. This isn't about just making more pipe; it's about making better pipe. We use advanced welding techniques, non-destructive testing[^2], and meticulous surface finishing to ensure every meter of 304 SS pipe we produce is ready for demanding applications, from food processing plants in Europe to petrochemical facilities in the Middle East.

The Power of Integration

The true competitive advantage lies in supply chain integration. A company like MFY isn't just a factory; we are part of a network that spans from raw material procurement to final logistics. This vertical integration gives us incredible control over costs, quality, and timelines. We can manage fluctuations in raw material prices more effectively and ensure a consistent supply of high-grade inputs. This structure allows us to offer the factory-direct pricing that our clients depend on, cutting out unnecessary middlemen and providing a clear, transparent procurement process.

| Industry Characteristic | Implication for Global Buyers |

|---|---|

| Massive Scale | Unmatched production capacity for large-scale projects. |

| Quality Focus | Adherence to international standards (ASTM, EN). |

| Integration | Cost control, supply stability, and direct pricing. |

| Innovation | Access to advanced manufacturing technologies. |

What are the Current Trends in Bulk Pricing for 304 SS Pipes?

Price volatility is a major concern. Unpredictable costs can ruin project budgets. We focus on providing transparent, stable pricing based on raw material costs and production efficiency.

Current trends show that bulk pricing for 304 SS pipes is heavily influenced by raw material costs (like nickel), production efficiency, and economies of scale. Direct-from-factory models increasingly offer the most competitive and stable pricing.

I speak with procurement managers every day, and their biggest challenge is often budget predictability. The stainless steel market can be volatile, and understanding the forces that drive prices is key to making smart purchasing decisions. While global market dynamics play a role, our direct-from-factory model is designed to shield our partners from as much of this volatility as possible by focusing on the factors we can control: efficiency and transparency.

Key Pricing Drivers

The price of 304 stainless steel is fundamentally tied to the cost of its core components. Nickel is the most significant and volatile element, and its price on the London Metal Exchange (LME)[^3] has a direct impact on our costs. Chromium, energy costs, and even currency exchange rates also play a role. However, a manufacturer's operational efficiency is a powerful counter-balance. By optimizing our production processes, minimizing waste, and leveraging our purchasing power for raw materials, we can absorb some of these market shocks and offer more stable pricing.

The Factory-Direct Advantage

This is where our model truly shines. By engaging directly with us, you bypass the layers of distributors and traders who each add their own margin. This not only results in a more competitive price but also creates a more transparent relationship. I remember a client in India who was struggling with unpredictable price hikes from a local supplier. By switching to our direct model, we were able to provide them with a clear cost structure tied to LME nickel prices, giving them the foresight needed to budget their projects accurately. This is the kind of partnership we strive to build.

| Cost Component | Volatility | MFY's Mitigation Strategy |

|---|---|---|

| Nickel | Высокий | Bulk purchasing, hedging strategies, transparent pricing. |

| Chromium | Средний | Long-term supplier contracts. |

| Energy | Средний | Investment in energy-efficient manufacturing. |

| Labor & Overhead | Низкий | Continuous process optimization and automation. |

What are the Key Challenges in Global Export Logistics for 304 SS Pipes?

Shipping heavy industrial goods is complex. Delays and customs issues are common frustrations. We see these not as problems, but as puzzles we've learned to solve efficiently.

The primary challenges in global export logistics include managing complex customs documentation, navigating volatile shipping costs and container availability, and ensuring the physical integrity of heavy, bulky products like stainless steel pipes during transit.

Manufacturing a perfect product is pointless if it doesn't arrive at the client's site on time and in perfect condition. The journey from our factory door to a construction site in another hemisphere is filled with potential pitfalls. Over the years, we've encountered nearly every possible challenge, and that experience is now one of our greatest assets. The logistics of exporting stainless steel pipes require more than just booking a container; it demands foresight, precision, and a deep understanding of global trade regulations.

Navigating the Customs Maze

Every country has its own set of import regulations, tariffs, and documentation requirements. A small error on a bill of lading[^4] or a certificate of origin[^5] can lead to significant delays and costly fines. For our clients, these delays can mean stalled projects and financial penalties. That's why having an experienced in-house logistics team is critical. We manage all the paperwork meticulously, ensuring that every shipment complies with the specific regulations of the destination port, whether it's in Santos, Brazil, or Jebel Ali, UAE.

The Physical Journey

Stainless steel pipes are heavy, long, and susceptible to surface damage if not handled correctly. Protecting them during thousands of nautical miles of transit is a science. We have to consider everything from proper bundling and crating to the weight distribution inside the container to prevent shifting during rough seas. I recall a shipment to a client in Australia where the pipes were for a high-purity application. We developed a custom packaging solution with extra internal padding and moisture-proof wrapping to guarantee they arrived without a single scratch or sign of corrosion. This attention to detail is standard procedure for us.

What Strategies Can Overcome These Export Logistics Challenges?

Logistics hurdles seem unavoidable. They can stall your entire project timeline. A strategic, proactive approach with an experienced partner can transform these challenges into a streamlined process.

Effective strategies include partnering with manufacturers who have in-house logistics teams, leveraging digital tracking platforms for real-time visibility, optimizing packaging for protection and container space, and consolidating shipments to manage costs.

Identifying challenges is easy; solving them is what defines a reliable partner. At MFY, we've built our logistics strategy around a single principle: taking ownership of the entire process. We don't just hand off our products to a third-party forwarder and hope for the best. We actively manage the journey from start to finish, using a combination of expertise, technology, and strong relationships to ensure a smooth and predictable delivery for our clients.

The Integrated Logistics Partner

Our biggest advantage is our dedicated, in-house logistics department. This team works hand-in-hand with our production and sales departments. This synergy means that logistics planning begins the moment an order is placed, not after the pipes are manufactured. We have established relationships with major shipping lines, which gives us priority access to containers and more competitive freight rates, even during periods of high demand. This integration allows us to provide our clients with accurate shipping schedules and reliable delivery timelines, which are crucial for project planning.

Smart Packaging and Consolidation

We view packaging as a critical part of the product itself. Our engineers have developed standardized and custom packaging solutions to maximize protection while optimizing container space. For example, by carefully nesting pipes of different diameters, we can increase the total tonnage per container, which significantly reduces the per-unit shipping cost for our clients. For smaller orders, we offer consolidation services, combining multiple clients' shipments into a single container to make exporting smaller quantities economically viable.

| Logistics Challenge | MFY's Proactive Solution |

|---|---|

| Customs Complexity | In-house experts manage all documentation for compliance. |

| Freight Volatility | Strong partnerships with shipping lines for preferential rates. |

| Product Damage | Engineered packaging and loading protocols. |

| Lack of Visibility | Digital tracking and regular communication with clients. |

How is Technology Innovating 304 SS Pipe Manufacturing and Export?

The steel industry can seem old-fashioned. You wonder if you're getting the latest advancements. We are actively integrating technology to enhance quality, transparency, and efficiency.

Technology is revolutionizing the industry through automated production lines for higher precision, digital platforms for transparent order tracking, and advanced material testing. These innovations improve product quality, supply chain visibility, and overall customer experience.

Innovation is at the heart of MFY's mission. We are constantly exploring and investing in new technologies that can make our products better and our processes more efficient. This commitment extends beyond the factory floor and into every aspect of our supply chain. For our clients, this means higher quality products, more reliable deliveries, and a more transparent partnership. Technology isn't just a buzzword for us; it's a practical tool we use to deliver tangible value.

Automation in the Factory

Our manufacturing facilities incorporate a high degree of automation. Processes like laser welding[^6], automated cutting, and robotic polishing ensure a level of consistency and precision that is difficult to achieve with manual methods alone. For example, our automated welding systems create seams that are stronger and more uniform, which is critical for high-pressure applications. This technology also allows us to increase our production speed without compromising on quality, enabling us to meet tight project deadlines for our clients.

Digitalization of the Supply Chain

Transparency is built on information. We are implementing digital platforms that give our clients real-time visibility into their orders. From a secure online portal, they can track the status of their order from production scheduling to the moment it's loaded onto a vessel. They can access quality control documents, inspection reports, and shipping information at any time. This digital connection removes uncertainty and empowers our clients with the data they need to manage their own operations effectively. It transforms the client-supplier relationship into a true, data-driven partnership.

Заключение

Sourcing from China's 304 SS pipe industry offers more than just a product; it provides a strategic partnership. By leveraging scale, technology, and integrated logistics, manufacturers like MFY deliver a competitive edge through reliable, cost-effective, and resilient supply chain solutions for your global projects.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.