Сертификация CE-PED для оборудования, работающего под давлением: Контрольный список поставщиков труб

Are you struggling to break into the European market for pressure equipment? The Pressure Equipment Directive (CE-PED) certification can often feel like an insurmountable barrier, locking your high-quality products out of a lucrative market while certified competitors win the bids you should be competing for.

CE-PED certification is a mandatory conformity mark for pressure equipment sold within the European Economic Area. Governed by Directive 2014/68/EU, it verifies that products like pipes and tubes meet essential safety, design, manufacturing, and testing standards to ensure public safety.

Navigating the path to certification can seem daunting at first. I’ve spoken with countless clients, from manufacturing firms to EPC contractors, who initially view it as a complex regulatory hurdle. However, shifting your perspective is key. Before diving into the technical checklists and audit preparations, it’s crucial to understand that this certification is more than a requirement; it's a strategic asset. It's your passport to one of the world's most significant industrial markets, and embracing the process is the first step toward unlocking that potential.

This journey is not merely about compliance; it's about embedding excellence into your operations. From a critical standpoint, the investment in CE-PED certification forces a rigorous self-evaluation of your quality management, material traceability, and production controls. While the initial costs and effort can be substantial, they are far outweighed by the long-term benefits. Industry data consistently shows that certified suppliers command greater trust and often secure more favorable contracts. It transforms a supplier from a commodity provider into a trusted partner in high-stakes projects. For us at MFY, achieving and maintaining this certification wasn't just about opening a new market; it was a testament to our commitment to the values of agility, resilience, and quality that our brand is built on.

В чем важность сертификации CE-PED для оборудования, работающего под давлением?

Do you view the CE mark as just another administrative task or a piece of paperwork? This common misconception can be costly, leading you to underestimate its profound impact on your business and the significant risks associated with non-compliance in the highly regulated European market.

The primary importance of CE-PED certification is that it provides a legal "passport" for pressure equipment to enter and be sold across the 30 countries of the European Economic Area. It signifies that your products meet harmonized safety standards, mitigating risks and ensuring quality.

For us at MFY, and for our clients, the CE-PED mark is far more than a customs formality; it's a declaration of safety and reliability. I recall a major project with an engineering contractor in Italy responsible for constructing a new chemical processing facility. They were explicit from our first conversation: our PED certificate was the non-negotiable prerequisite for even being considered. The reason wasn't just about our stainless steel pipe's metallurgical properties, which they could test. It was about the certified, documented, and independently audited assurance of our entire production process, from raw material sourcing to final inspection and testing. This certification provided them with the confidence they needed to manage their own project risks, ensuring that the components they integrated would perform safely under immense pressure. This experience, and many others like it, constantly reinforces that the importance of PED extends deep into the operational and commercial fabric of the global supply chain, serving as a critical pillar of trust.

The significance of the CE-PED certification is multifaceted, touching upon legal obligations, safety imperatives, and profound commercial advantages. Viewing it solely as a regulatory hurdle is a missed opportunity. Instead, it should be seen as a strategic framework that enhances product quality, builds customer trust, and unlocks significant economic potential. For any pipe supplier with ambitions in the European market, a deep and practical understanding of its importance is not just beneficial—it is absolutely essential for long-term success. It redefines a supplier's position in the market, elevating them from a simple component provider to a critical partner in ensuring the safety and integrity of major industrial projects across the continent. This holistic view is what drives our commitment to maintaining the highest standards at MFY.

Beyond Market Access: CE-PED as a Pillar of Trust and Safety

The fundamental reason for the Pressure Equipment Directive's existence is safety. It was established to harmonize disparate national laws and prevent catastrophic failures of pressure equipment, which can have devastating consequences for life, property, and the environment. For a pipe supplier, this means our products are often the veins and arteries of critical systems, whether in a power plant, a pharmaceutical factory, or a food processing facility. A failure in these systems is not an option. The PED framework mandates a rigorous approach to design, materials, and manufacturing, ensuring that every certified component is fit for its demanding purpose.

This focus on safety directly translates into a powerful risk mitigation tool for our clients. When an Engineering & Construction Contractor specifies PED-certified stainless steel tubes for a project, they are effectively managing their own liability. They are relying on the documented evidence and the independent verification of a Notified Body that the materials meet EU-wide safety standards. This simplifies their own compliance journey, streamlines their quality audits, and provides their end-client with verifiable proof of quality. It shifts the burden of proof for material conformity to the manufacturer, who has already undergone the rigorous certification process.

Consider a typical client of ours, an equipment integrator in the Netherlands that specializes in building high-pressure pasteurization systems for the dairy industry. The integrity of the stainless steel tubing carrying superheated steam is paramount to the safety and functionality of their final product. For them, our PED 2014/68/EU certification is not a "nice-to-have" feature; it is a foundational requirement for their own CE marking process on the completed assembly. Their entire business model and reputation depend on sourcing components from suppliers who not only claim quality but can prove it through internationally recognized, legally binding certification.

The Economic Imperative: Unlocking Commercial Opportunities

Beyond the critical aspect of safety, the economic driver for CE-PED certification is undeniable. The certification grants unrestricted access to the European Economic Area1, which includes the 27 member states of the European Union plus Iceland, Liechtenstein, and Norway. This represents one of the largest and most technologically advanced industrial markets in the world. For a company like MFY, which is dedicated to expanding the global reach of China's stainless steel supply chain, the EU market is a strategic priority. Without PED certification, this entire market remains closed.

This access creates a significant competitive advantage. In a competitive tender situation, a procurement manager for a large manufacturing company is tasked with making the safest and most reliable choice. Presented with two potential suppliers—one certified, one not—the decision becomes simple. The certified supplier has already been vetted by an independent European authority, effectively de-risking the procurement decision. I have personally seen how our CE-PED certification has enabled MFY to compete on equal footing with long-established European mills. It neutralizes the question of origin and focuses the conversation on technical specifications, delivery speed, and overall value, which are our core strengths.

To illustrate the commercial impact, consider the risk assessment from a client's perspective when choosing a pipe supplier for a project within the EU:

| Factor | With CE-PED Certified Supplier (e.g., MFY) | With Non-Certified Supplier |

|---|---|---|

| Market Access | Unrestricted access to the EEA market. | Shipments can be blocked by customs, causing severe project delays. |

| Legal & Regulatory Risk | Low. Liability for material conformity is clearly defined. | High. The importer/user bears full responsibility for proving compliance. |

| Project Timelines | Smooth. Materials are pre-approved for use, preventing compliance delays. | High risk of material rejection, re-testing, and schedule overruns. |

| Insurance & Financing | Favorable. Lower perceived risk can lead to better insurance terms. | Difficult. Insurers and financiers may view the project as high-risk. |

| Brand & Client Trust | Enhanced. The supplier is seen as a reliable, quality-focused partner. | Damaged. Association with non-compliance can harm reputation. |

Harmonization and Supply Chain Efficiency

One of the most powerful but often overlooked benefits of the CE-PED framework is the harmonization of technical standards across all member states. A stainless steel tube that is certified as compliant for a project in Germany is automatically accepted for use in France, Poland, or Spain without the need for additional local testing or country-specific approvals. This eliminates a massive layer of complexity and bureaucracy that existed before the Directive, creating a truly single market for industrial goods.

From our perspective as a manufacturer and global supplier, this harmonization is a cornerstone of our operational strategy. It allows us to streamline our production processes and inventory management. We can manufacture our stainless steel pipes to a single, high standard—the PED standard—with the full confidence that this stock is eligible for our diverse client base across Europe. This is a key enabler of our ability to maintain a strong inventory for rapid export delivery, which is a critical part of our value proposition to clients who need to keep their projects on schedule.

This efficiency directly benefits our clients, whether they are distributors, traders, or contractors. A distributor based in Poland can source a container of PED-certified pipes from MFY in China, knowing they can confidently resell those same pipes to a construction contractor in Portugal or an equipment manufacturer in Belgium. This creates a seamless, agile, and highly efficient pan-European supply chain. It empowers our partners to be more competitive in their own markets. Ultimately, this level of integration and reliability is precisely what our mission at MFY aims to foster: driving the global expansion of a resilient and technologically advanced stainless steel supply chain.

CE-PED is mandatory for EU market accessПравда

The CE-PED certification is legally required for pressure equipment sold in the European Economic Area under Directive 2014/68/EU.

CE-PED only benefits large manufacturersЛожь

CE-PED certification creates competitive advantages for suppliers of all sizes by providing market access and building trust with clients.

Как поставщики труб могут подготовиться к сертификации CE-PED?

Is the prospect of a PED certification audit causing you anxiety? The sheer volume of technical documentation, quality control procedures, and traceability requirements can feel like an insurmountable mountain to climb, especially when you’re managing day-to-day production and sales operations.

Suppliers can prepare for a CE-PED audit by first performing a gap analysis of their systems against the Directive's requirements. This involves establishing a robust Quality Management System (QMS), compiling detailed technical documentation, ensuring full material traceability, and selecting a suitable Notified Body.

Preparation is a strategic project, not an administrative one. It’s a fundamental cultural shift towards making quality assurance visible and provable. At MFY, our journey to certification was transformative. We didn't just write new procedures; we critically re-evaluated our entire value chain, from how we qualify raw material suppliers to our final marking and packing processes. I recall the intensive workshops our engineering, procurement, and quality assurance teams held, meticulously mapping every step against the PED annexes. This deep-dive process is demanding but invaluable. It forces you to challenge assumptions and build a system that doesn’t just claim compliance but demonstrates it irrefutably. This foundational work is what separates suppliers who simply want a certificate from those who truly embody the principles of safety and quality it represents. We will now break down the actionable stages of this crucial preparation journey.

The path to CE-PED certification is a marathon, not a sprint. It demands careful planning, dedicated resources, and an unwavering commitment from every level of the organization. By approaching it systematically—building a strong QMS foundation, meticulously preparing technical and material documentation, and choosing the right expert partners—a supplier can turn a daunting challenge into a strategic achievement. This preparation is an investment in the very core of your business. It enhances your processes, upskills your team, and ultimately builds a more resilient and competitive organization. As a director at MFY, I can attest that the discipline instilled by the PED preparation process has paid dividends far beyond simply gaining access to the European market; it has made us a better manufacturer.

Foundational Step: Establishing a Compliant Quality Management System (QMS)

The bedrock of any successful PED certification is a robust and well-implemented Quality Management System (QMS). PED Annex I, section 3.1.2, explicitly requires that the material manufacturer has an appropriate quality-assurance system, certified by a competent body. While many suppliers may already have ISO 9001 certification, this is just the starting point. The key is to ensure your QMS is specifically tailored to address the stringent requirements of the Pressure Equipment Directive. This means your existing procedures for document control, records management, internal audits, and corrective actions must be viewed through the lens of pressure equipment safety.

In practice for a stainless steel pipe manufacturer, this involves integrating PED-specific controls directly into the QMS. For example, your document control procedure must manage not only internal drawings but also the receipt, verification, and storage of material test certificates (MTCs) from your raw material suppliers. Your internal audit schedule must include specific checks for PED compliance, such as verifying that material marking procedures are being followed correctly on the production floor. At MFY, we revised our entire QMS manual to create a dedicated section addressing PED requirements, ensuring that every relevant clause of the directive was linked to a specific internal procedure and a responsible party.

This foundational work is critical, and it’s an area where many suppliers falter. I once consulted with a manufacturing company in Southeast Asia that was aiming to become a supplier for one of our European clients. They had an ISO 9001 certificate, but their system was superficial. It lacked the granular controls for material traceability and welder qualification records that are non-negotiable under PED. We advised them to first focus on strengthening their QMS. This involved implementing a "positive material identification" (PMI) process at goods-in, and creating a more rigorous system for tracking welding procedure qualification records (WPQRs). This internal overhaul took six months, but it was essential before they could confidently engage a Notified Body for an audit.

The Heart of Compliance: Technical Documentation and Material Control

With a strong QMS in place, the next critical phase is the compilation of the Technical File and the establishment of foolproof material control. The Technical File is the body of evidence you present to the Notified Body to prove your product's compliance. For pipes and tubes, this file must contain a wealth of information, including material specifications, manufacturing processes, details of non-destructive testing (NDT) personnel and procedures, welding procedure specifications (WPS), and, most importantly, the material test certificates that prove the chemical and mechanical properties of your products.

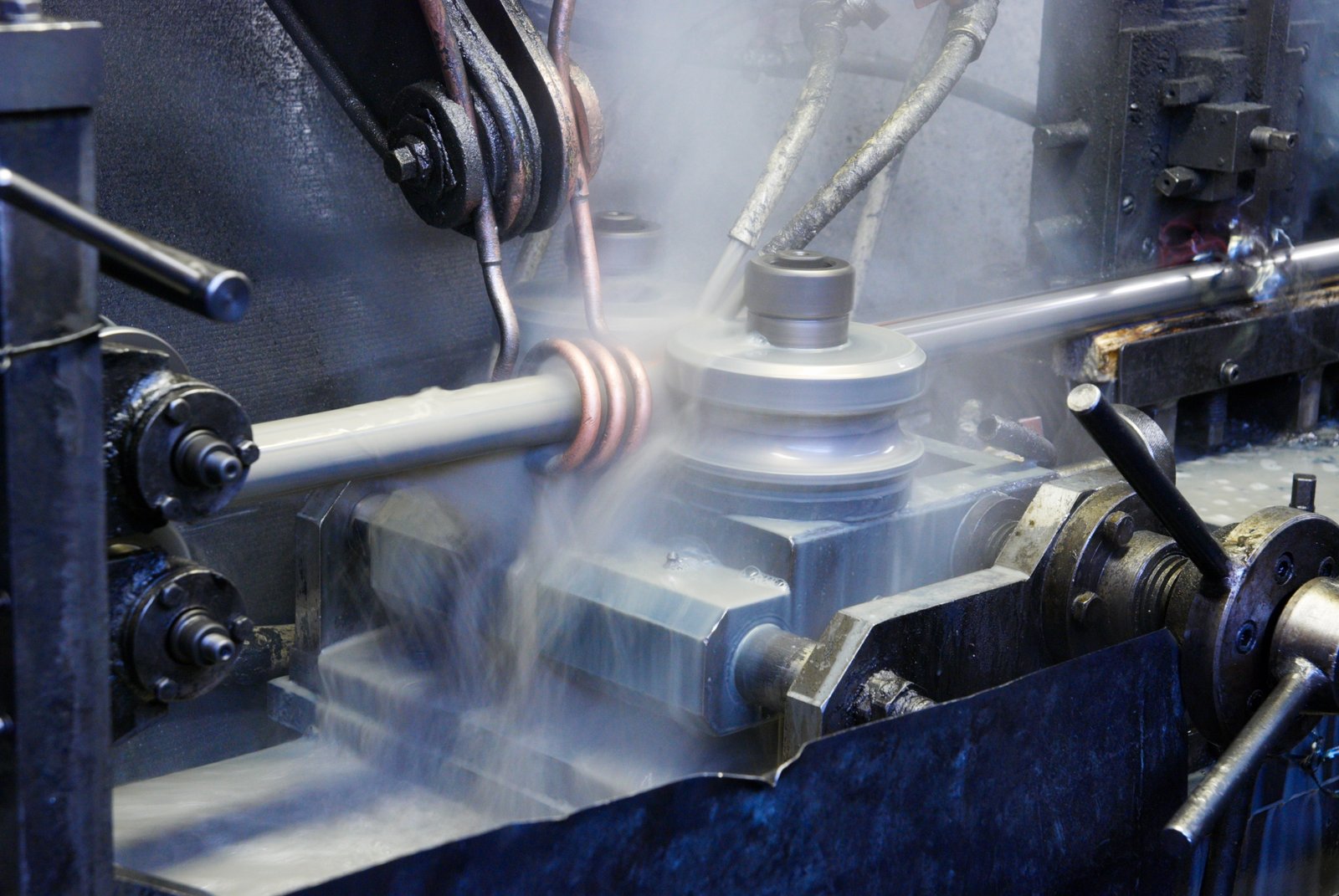

Material traceability is the absolute heart of PED compliance for a material manufacturer. There must be an unbroken and verifiable chain of documentation from the original steel melt at the mill to the finished, marked pipe leaving your facility. The standard for this is the EN 10204 material certificate. For most pressure applications, a 3.1 certificate is required. This certificate is issued by the material manufacturer (us) and declares that the products are in compliance with the order requirements, supported by specific test results from our own laboratories. It's a formal declaration of quality. At MFY, our digital ERP system is the backbone of this process. Every coil of raw material is assigned a unique batch number upon arrival, which is linked to the supplier's original heat number and their MTC. This batch number follows the material through slitting, tube forming, welding, heat treatment, and final testing, and is ultimately marked on the finished pipe.

This allows us to achieve what is known as "positive traceability." At any point, we can take a finished pipe from our inventory, read its marking, and within minutes, pull up its complete manufacturing history and the original 3.1 certificate in our system. This isn't just a process we run for an audit; it is a permanent quality assurance discipline that underpins the integrity of every PED-certified product we ship. This level of control gives our clients—and in turn, their clients—complete confidence in the material they are installing.

Engaging the Right Partners: Selecting a Notified Body (NoBo)

The final preparatory step is the strategic selection of a Notified Body (NoBo). A Notified Body is an independent organization designated by an EU member state to perform the conformity assessment tasks specified in the legislation. You cannot self-certify for most pressure equipment; you must be audited and approved by a NoBo. Choosing the right NoBo is a critical decision that can significantly impact the efficiency and success of your certification process. It is not a commodity service; it is a long-term partnership with a technical expert.

When selecting a NoBo, your primary consideration should be their experience and accreditation in your specific field—in our case, metallic materials and tube manufacturing. Different NoBos have different strengths. Some may be experts in boilers, while others specialize in valves or materials. You must verify that they are notified under PED 2014/68/EU2 for the relevant conformity assessment modules (e.g., Module D1 for Quality Assurance) and for your specific material type. Beyond their technical scope, consider factors like their global presence, particularly if your manufacturing facilities are outside the EU. A NoBo with qualified local auditors can save significant time and travel costs.

Before we began our certification at MFY, I personally held introductory meetings with senior auditors from three different Notified Bodies. I prepared a detailed list of questions that went far beyond pricing. I asked about their audit philosophy, their experience with stainless steel tube mills in Asia, their typical timeline from application to certification, and how they handle non-conformities. I was looking for a partner who was rigorous but fair, and who demonstrated a deep understanding of our industry's specific challenges. We ultimately chose the NoBo that communicated most clearly and demonstrated the most relevant technical expertise. My advice to any supplier is to invest time in this selection process. Treat it as if you were hiring a crucial consultant. The right NoBo will act as a valuable guide through the complexities of the directive, while the wrong one can lead to confusion, delays, and frustration.

Gap analysis is essential for PED preparationПравда

Performing a gap analysis helps identify discrepancies between current systems and PED requirements, forming the basis for certification preparation.

ISO 9001 alone ensures PED complianceЛожь

While ISO 9001 provides a foundation, PED requires additional specific controls for material traceability and safety documentation.

Каковы основные требования для получения сертификата CE-PED?

Are you clear on what an auditor will actually look for during a PED assessment? Many suppliers focus on the final product but overlook the comprehensive system requirements that underpin the certification. It's a common blind spot that can lead to unexpected and critical audit failures.

The key requirements for CE-PED certification encompass a certified Quality Management System (like ISO 9001), full material traceability with EN 10204 certificates, qualified personnel for key tasks (e.g., NDT, welding), and a complete Technical File demonstrating product compliance.

Achieving certification is not a single event but the outcome of a holistic system that meets specific, non-negotiable benchmarks set by the Directive. It's about proving you have control over your materials, your processes, and your people. As the Global Business Director at MFY, I’ve guided our teams through numerous audits, and the focus is always the same: evidence. Auditors are not interested in promises; they demand objective, documented proof. For instance, when they review our welding procedures, they don’t just read the document; they cross-reference it with the qualification records of the welder who performed the job and the calibration records of the machine that was used. This interconnected web of evidence is the core of the audit process. Understanding these key requirements in detail is the only way to build a system that is not just compliant on paper, but robust in practice.

Meeting the key requirements of the Директива по оборудованию, работающему под давлением (PED)3 is a demanding but achievable goal. It requires a supplier to move beyond traditional quality control and embrace a more integrated system of quality assurance. The focus must be on provable, documented control over every critical aspect of production. From the foundational QMS and the unwavering discipline of material traceability to the validated expertise of your personnel and the comprehensive evidence in your Technical File, each element is a critical link in the chain of compliance. At MFY, we have found that embedding these requirements into our daily operations has not only ensured our ongoing certification but has also driven continuous improvement across our organization. It has reinforced our commitment to providing world-class products and has solidified our reputation as a trusted partner in the global stainless steel supply chain, capable of meeting the most stringent international standards.

Requirement 1: A Certified and Tailored Quality Management System

The first and most fundamental requirement is the operation of a formal Quality Management System (QMS), which must itself be certified by a competent body. For material manufacturers like us, PED Annex I, Section 4.3, points towards the need for a certified system, with ISO 9001 being the universally accepted benchmark. However, simply holding an ISO 9001 certificate is not sufficient. The crucial requirement is that the QMS must be specifically adapted and proven to manage the risks associated with pressure equipment. The Notified Body auditor will scrutinize your QMS to ensure it effectively controls all PED-relevant activities.

This means your QMS procedures must explicitly reference and address the essential safety requirements (ESRs) of the directive. For example, your procedure for 'Control of Production' must include specific steps for how welding is controlled, how heat treatment parameters are monitored and recorded, and how non-destructive testing is performed. Your 'Purchasing' procedure must detail the process for approving suppliers of critical raw materials and for verifying the conformity of incoming MTCs. You must be able to demonstrate, through records, that these procedures are consistently followed.

During one of our surveillance audits, the NoBo auditor picked a random production order from six months prior. He then asked to see the complete documentation package: the raw material MTC, the internal work order, the welding parameters log, the NDT report, and the final 3.1 certificate we issued. Our ability to produce this complete, consistent, and cross-referenced package within minutes was a direct result of having a QMS that is deeply integrated with PED requirements, not just compliant on the surface. This is the level of rigor the directive demands.

Requirement 2: Unbroken Material Traceability and Certification

Perhaps the single most critical requirement for a pipe supplier under PED is establishing and maintaining unbroken material traceability. The directive is built on the principle that the properties of the materials used are known, verified, and documented. This traceability must be physical (the marking on the pipe) and documentary (the chain of certificates). The key document in this process is the inspection certificate according to EN 10204. For most pressure-bearing parts, a 3.1 certificate is the minimum requirement.

A 3.1 certificate is a declaration by the manufacturer (MFY, in this case) that the products supplied are in compliance with the requirements of the order and are supported by test results from specific inspections on the actual batch of products. This is a significant responsibility. It means we cannot simply rely on the raw material supplier's data; we must have our own calibrated testing equipment and competent personnel to perform tests like tensile, hardness, and chemical analysis, and to record these results against the specific production batch. The link between the test results, the certificate, and the physical marking on the pipe must be unbreakable.

Let's consider a practical example from our production floor. A single coil of stainless steel might be used to produce several thousand meters of pipe. Our system ensures that every single pipe produced from that coil carries a unique batch number. That batch number is linked to our internal test reports and the original raw material heat number. If a client, years later, has a question about a specific pipe installed in their facility, they can give us the number marked on it, and we can provide the full material history and the 3.1 certificate, proving its compliance at the time of manufacture. This requirement is non-negotiable and is often the area of greatest scrutiny during an audit.

Requirement 3: Qualified Personnel and Validated Procedures

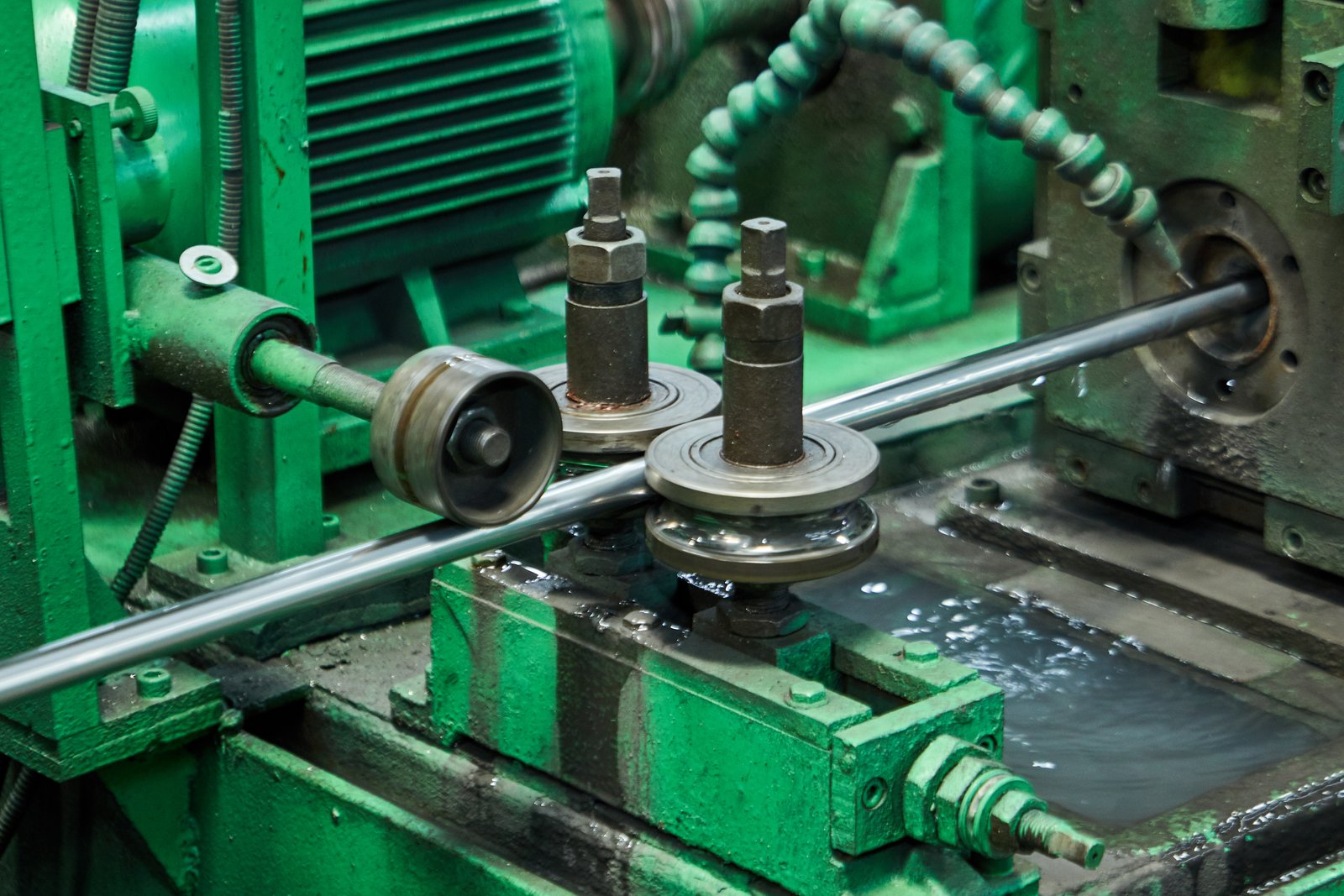

The PED requires that tasks critical to the integrity of the pressure equipment must be performed by competent personnel using qualified procedures. For a stainless steel tube manufacturer, the two most important areas are welding and non-destructive testing (NDT). It is not enough to simply say you have skilled workers; you must provide objective, third-party-verified evidence of their competence.

For welding, this means that the welding procedures used to make the pipe seam (Welding Procedure Specification, WPS) must be formally qualified by a Notified Body or a recognized third party. Furthermore, the operators who oversee the automated welding machines must be qualified in accordance with relevant standards (e.g., ISO 14732). These qualifications are not permanent; they have expiry dates and must be periodically re-validated. All of these records—WPS, PQR (Procedure Qualification Record), and welder qualifications—must be maintained and available for audit.

Similarly, any personnel performing NDT (such as eddy current testing or ultrasonic testing) to check the integrity of the weld seam must be certified to a recognized scheme like ISO 9712 (Level 1, 2, or 3). The NDT procedures themselves must also be documented and validated. This ensures that the tests are not only performed by qualified individuals but are also conducted in a reliable and repeatable manner. At MFY, we maintain a detailed matrix of our key personnel, listing their qualifications, certification numbers, and expiry dates. This is reviewed monthly by our QA manager to ensure we are always in a state of compliance and readiness for an unannounced audit.

ISO 9001 alone isn't sufficient for PEDПравда

The QMS must be specifically adapted to address PED's essential safety requirements, not just generic ISO 9001 compliance.

Material traceability is optionalЛожь

PED mandates unbroken physical and documentary traceability with EN 10204 certificates as a fundamental requirement.

Какие шаги должны предпринять поставщики труб для обеспечения соответствия стандартам CE-PED?

Do you have a clear action plan for turning PED requirements into daily practice? Knowing the rules is one thing, but implementing a robust system to ensure consistent, ongoing compliance is a far greater challenge. Without concrete steps, compliance can easily become a theoretical goal rather than an operational reality.

To ensure compliance, suppliers must first conduct a thorough gap analysis, then develop and implement PED-specific procedures within their QMS. This is followed by rigorous training of all relevant staff, conducting internal pre-audits, and establishing a system for permanent material traceability.

Ensuring compliance is an active, dynamic process, not a passive state. It's about building a living system that integrates the directive's demands into the very fabric of your company's operations. In my role at MFY, I stress to our teams that compliance isn't the job of the QA department alone; it's a shared responsibility. The procurement team ensures compliant material sourcing, the production team follows qualified procedures, and the sales team communicates technical specifications accurately. This journey begins with a single, critical step: honestly assessing where you are versus where you need to be. This gap analysis forms the blueprint for all subsequent actions, turning the broad requirements of the directive into a concrete, customized action plan for your facility, your people, and your products.

Ensuring ongoing compliance with CE-PED standards is a journey of continuous improvement, not a destination. It requires a structured, systematic approach that begins with a clear understanding of your current gaps and culminates in a culture of quality that is embraced across the entire organization. The steps—from analysis and procedural development to rigorous training and vigilant internal auditing—create a resilient framework that not only satisfies Notified Body auditors but also builds profound trust with clients. For us at MFY, these steps are not just about maintaining a certificate on the wall. They are the practical application of our core value of resilience, ensuring we are always prepared, always improving, and always delivering products that meet the highest global standards of safety and quality.

Step 1: Conduct a Detailed Gap Analysis and Create a Project Plan

The very first practical step on the path to compliance is to conduct a thorough gap analysis4. You cannot create a roadmap until you know your starting point. This involves a meticulous, clause-by-clause comparison of your current operational procedures, documentation, and quality systems against the specific requirements of the PED 2014/68/EU directive and any relevant harmonized standards (e.g., EN 764 for pressure equipment terminology and symbols). This should be a formal process, led by a dedicated project manager or team.

The analysis should cover all relevant areas: the existing QMS, material sourcing and traceability, production processes (especially welding and heat treatment), NDT procedures, personnel qualifications, and technical documentation practices. The output should be a detailed report that identifies every gap, from minor procedural omissions to major systemic deficiencies. For example, a gap might be "Procedure for calibration of testing equipment does not specify a recall system" or a more critical one like "No EN 10204 3.1 certificates are available for existing raw material inventory."

Once the gap analysis report is complete, the next move is to transform it into a time-bound project plan. Each identified gap becomes a task, assigned to a responsible person or department with a clear deadline. This plan becomes your central tool for managing the compliance project. When we first undertook this at MFY, our project plan had over 100 individual action items, ranging from rewriting QMS procedures to purchasing new calibrated measuring tools and arranging third-party qualification for our welding procedures. This structured approach was vital to ensure nothing was missed.

Step 2: Develop and Implement PED-Specific Procedures and Training

With a clear project plan, the core activity is to develop, revise, and implement the necessary procedures to close the identified gaps. This is where the requirements of the directive are translated into the specific language and context of your own factory. If your gap analysis showed a weakness in material traceability, you need to write and implement a new, detailed procedure that covers every step: how material is received, how it is identified and marked, how it is issued to production, and how the final product is marked to link back to the original material.

This is not just a paperwork exercise. The implementation is the most critical part. A new procedure is useless if the people on the shop floor are not aware of it or do not follow it. Therefore, this step must be intrinsically linked with comprehensive training5. You must train every individual whose role is impacted by the new or revised procedures. This includes procurement staff (on how to verify MTCs), warehouse staff (on new material segregation rules), production operators (on following qualified WPS), and QA inspectors (on new inspection checkpoints).

At MFY, we conducted a series of mandatory training workshops for different departments. For our production team, we didn't just give them a new document to read. We held practical sessions on the factory floor, demonstrating the new marking requirements and explaining why this traceability was so critical for safety and for our clients. We created quizzes and competency checks to ensure the information was understood. Documenting this training is also a key requirement; it provides the evidence that your personnel are competent.

Step 3: Execute Internal Audits and Management Reviews

Before you invite a Notified Body for the official audit, you must become your own toughest critic. The third step is to establish a rigorous internal audit program specifically focused on PED compliance. This internal audit should be conducted by trained auditors (who can be internal staff, but ideally not auditing their own department) and should use a detailed checklist based directly on the directive's requirements. The goal is to simulate the real audit and find any remaining non-conformities before the external auditor does.

The internal audit should be unflinching. Auditors should interview staff, review records, and observe processes on the factory floor. Every non-conformity, no matter how small, should be formally documented in a corrective action report (CAR). The responsible department must then propose a root cause analysis and a plan to fix the issue, which is then tracked to completion by the QA manager. This continuous loop of auditing and correcting is the engine of continuous improvement.

Following the internal audit, the findings must be presented to senior leadership in a formal Management Review meeting. This is a specific requirement of ISO 9001 and is essential for PED. It ensures that top management is fully aware of the state of the QMS, the resources needed to maintain compliance, and the overall performance of the system. In my experience, visible commitment from leadership is a powerful motivator for the entire organization. When our CEO and plant manager actively participate in these reviews and ask challenging questions, it sends a clear message that PED compliance is a top-level business priority.

Анализ пробелов - первый шагПравда

The article clearly states that conducting a thorough gap analysis is the foundational first step in achieving PED compliance, as it identifies current deficiencies against requirements.

Compliance is only QA's responsibilityЛожь

The text explicitly states that PED compliance is a shared responsibility across procurement, production, and sales teams - not just the QA department.

Как поставщики труб могут поддерживать сертификацию CE-PED в течение длительного времени?

Have you considered what happens after the certificate is hung on the wall? Achieving certification is a major milestone, but many suppliers mistakenly believe the hard work is over. The reality is that maintaining certification requires a sustained, vigilant effort, and complacency can lead to a suspension of your market access.

To maintain CE-PED certification, suppliers must treat compliance as a continuous process. This involves conducting regular internal audits, holding management reviews, managing document control, providing ongoing training, and successfully passing periodic surveillance audits by the Notified Body.

Maintaining your CE-PED status is not a static achievement but a dynamic commitment to quality. It's about ensuring that the robust systems you built for the initial audit become the ingrained, everyday culture of your organization. I often tell my team at MFY that our certificate is not a trophy; it's a living document that we must re-earn every single day, with every pipe we produce. This mindset is crucial because your Нотифицированный орган6 will return for surveillance audits, typically annually. They will expect to see not just the same level of compliance, but evidence of continuous improvement. This requires a proactive, structured approach to maintenance, which we will now detail.

Maintaining CE-PED certification is a testament to an organization's enduring commitment to safety and quality. It is a continuous cycle of vigilance, not a one-time achievement. By embedding the principles of the directive into the company's culture through regular audits, continuous training, diligent document control, and robust change management, a supplier can ensure they are always "audit-ready." This sustained effort does more than just keep a certificate valid; it builds a resilient organization, fosters client trust, and solidifies a supplier's reputation as a reliable, long-term partner in the demanding European market. At MFY, this continuous maintenance is a cornerstone of our promise to deliver excellence and drive the global expansion of a truly quality-driven supply chain.

Maintenance Pillar 1: A Perpetual Cycle of Audits and Reviews

The most effective tool for maintaining certification is the relentless and systematic use of internal audits. Your initial certification audit should not be the last time you feel the pressure of a detailed inspection. A robust internal audit schedule, executed throughout the year, is the single best way to ensure your systems remain compliant. These audits should be just as rigorous as the external ones, covering all aspects of the PED-compliant QMS. They serve as a vital health check, identifying any procedural drift or non-conformities that may have crept in during routine operations before they become major issues.

Following each internal audit, the findings must be formally addressed through your corrective and preventive action (CAPA) system. A CAR (Corrective Action Request) should be issued for every non-conformity. It's not enough to simply fix the immediate problem; the system requires you to perform a root cause analysis to understand why the failure occurred and implement changes to prevent it from happening again. This data is then fed into the mandatory Management Review meetings.

These high-level meetings, which are required by ISO 9001 and expected by NoBos, are critical for maintaining leadership oversight. During our quarterly Management Reviews at MFY, we analyze internal audit results, customer feedback related to quality, process performance data, and the status of corrective actions. This ensures that the commitment to PED compliance remains a top-level strategic priority and that necessary resources are allocated for continuous improvement, whether it's for new testing equipment or additional staff training.

Maintenance Pillar 2: Proactive Management of Change (MOC) and Documentation

Business is not static. You will introduce new machines, update manufacturing processes, change key suppliers, or revise product designs. A critical aspect of maintaining PED certification is having a formal Management of Change (MOC) procedure. You cannot make changes that affect your PED compliance on an ad-hoc basis. Any proposed change must be formally reviewed for its potential impact on your certification. For example, if we decide to qualify a new supplier for our stainless steel coils, our MOC procedure requires that our QA department first audits them and verifies their ability to provide compliant material and EN 10204 3.1 certificates before any purchase order is placed.

This ties directly into the pillar of document control. Your technical files and quality manual are living documents. When a process is changed, the corresponding documentation—be it a WPS, a work instruction, or a flow chart—must be updated immediately through a formal change request process. Version control is critical. You must be able to demonstrate to an auditor that the procedure being used on the shop floor is the current, approved version.

At MFY, our digital QMS is invaluable here. When a procedure is updated, the system automatically archives the old version and notifies all relevant personnel that a new version is active. During a surveillance audit, the NoBo auditor will often test this. They might pick a procedure, check its version number in the system, and then walk to the factory floor to ensure the document available to the operator is the same, current version. This seemingly simple check is a powerful test of the maturity of your document control system.

Maintenance Pillar 3: Continuous Training and Competency Management

Your people are the guardians of your compliance system. A process is only as good as the person executing it. Therefore, continuous training and competency management are essential for long-term certification maintenance. This goes far beyond a one-time induction for new hires. You need a recurring training program to provide refreshers on critical procedures, communicate any changes to the QMS, and reinforce the importance of PED compliance.

This is especially critical for personnel in key roles. For example, the certifications for your welders and NDT operators have expiry dates. You must have a system to track these dates and arrange for re-qualification and refresher training well before they expire. A lapse in a key individual's qualification can lead to a major non-conformity during a surveillance audit, potentially halting the shipment of products. We maintain a "competency matrix" for all staff in PED-relevant roles, which is reviewed quarterly to plan future training needs.

Furthermore, training should evolve based on performance data. If your internal audits consistently find issues in a particular area, such as incorrect material marking, it's a clear indicator that targeted retraining is needed for the staff in that department. This responsive approach to training ensures your team's skills remain sharp and aligned with the demands of the directive. It transforms training from a compliance checkbox into a strategic tool for risk management and continuous improvement.

Internal audits maintain PED complianceПравда

Regular internal audits help identify procedural drift and non-conformities before they escalate, keeping the QMS compliant.

CE-PED is a one-time achievementЛожь

CE-PED certification requires continuous effort through audits, training, and documentation updates to maintain validity.

Заключение

In conclusion, achieving and maintaining CE-PED certification is a strategic imperative, not just a regulatory task. It's a journey that transforms a supplier’s processes, enhances product quality, and unlocks critical access to the European market, cementing your role as a trusted, safety-conscious global partner.

-

Discover commercial benefits of unrestricted access in the EEA market ↩

-

Understand the significance of PED and how NoBos are involved in the certification process ↩

-

Understand the essential requirements of PED required for certifying pressure equipment in Europe ↩

-

Discover how gap analysis can identify compliance shortfalls and form the base for strategic action. ↩

-

Learn training methods to ensure staff understands and implements PED-compliant procedures. ↩

-

Understand the responsibilities and functions of a Notified Body in auditing processes. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.