Global Certifications & Export Expertise: MFY Compliance Explained

Are you struggling to navigate the complex web of global stainless steel certifications? This uncertainty can lead to costly project delays and market access restrictions, hindering your international growth. As MFY's Global Business Director, I'll show you how our robust compliance framework ensures your success.

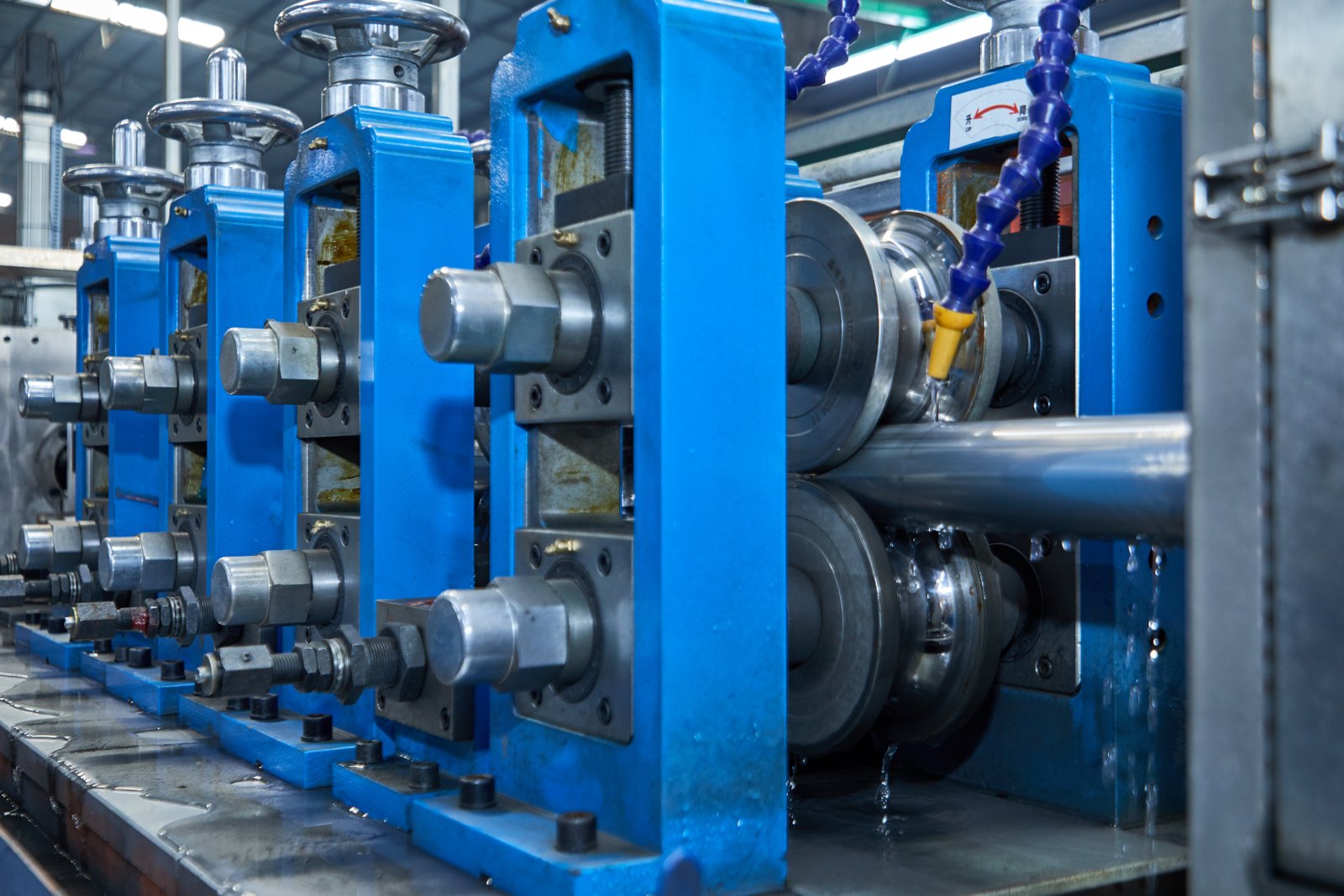

Understanding global certifications and export compliance is crucial for businesses sourcing stainless steel internationally. MFY navigates this by adhering to key standards like ISO 9001 and region-specific certifications, ensuring products meet stringent quality and safety requirements for diverse export markets, thus facilitating smoother global trade.

Navigating the labyrinth of international standards can be a daunting task for any business looking to source materials globally. The stainless steel industry, in particular, is governed by a multitude of certifications that vary by region and application. This complexity isn't just a bureaucratic hurdle; it's a critical factor that impacts product quality, safety, and your project's ultimate success.

At MFY, we don't just see compliance as a set of rules to follow; we view it as a cornerstone of our commitment to quality and a key enabler of our clients' global ambitions. The challenge, of course, is that the landscape of international certifications is constantly evolving. New standards emerge, existing ones are updated, and regional requirements can shift. For instance, the push for sustainability is introducing new environmental certifications that are rapidly gaining importance. Conversely, failing to keep pace can mean not just lost business opportunities but also potential legal and financial repercussions. We've invested heavily in understanding these nuances, from the broad strokes of ISO 9001 to the specific demands of ASTM, EN, or JIS standards, ensuring our stainless steel pipes and tubes meet the rigorous demands of clients in India, Southeast Asia, the Middle East, and Russia. This proactive approach, backed by our integrated supply chain, allows us to offer not just products, but peace of mind.

What are the key global certifications relevant to the stainless steel industry?

Confused about which certifications truly matter for your stainless steel needs? Without this clarity, you risk sourcing materials that don't meet project specifications or regulatory requirements, leading to significant setbacks. I'm here to demystify the essential global certifications for you.

Key global certifications in the stainless steel industry include ISO 9001 for quality management, CE Marking for European conformity, ASTM standards for North American markets, and PED for pressure equipment. These ensure product quality, safety, and compliance with international trade regulations, crucial for global sourcing.

Understanding the primary global certifications is the first step towards ensuring the quality and compliance of your stainless steel products. These certifications are not merely badges; they represent a commitment to internationally recognized standards of manufacturing, safety, and quality management. For businesses like manufacturing companies or engineering contractors, specifying and verifying these certifications can mean the difference between a successful project and one fraught with complications. At MFY, we regularly guide our clients through this landscape. For example, a construction contractor in Dubai recently approached us needing stainless steel tubes for a high-profile project with stringent safety and durability requirements. Their primary concern was ensuring full compliance with both local regulations and the project's specific engineering demands, which included specific ASTM and EN standards. We were able to walk them through our certification portfolio, explaining how each one addressed their specific needs, providing test certificates, and demonstrating our quality control processes. This transparency and expertise not only secured their confidence but also ensured the project proceeded smoothly with fully compliant materials. This proactive approach to certification education is vital, as the implications of non-compliance can range from project delays and budget overruns to, in worst-case scenarios, safety failures and legal liabilities. Therefore, a thorough understanding and verification of certifications are paramount.

The world of stainless steel certifications can seem like an alphabet soup, but each standard serves a critical purpose in ensuring quality, safety, and interoperability across global markets. As a Global Business Director at MFY, I've seen firsthand how crucial a deep understanding of these certifications is, not just for us as a supplier, but for our diverse clientele, from large manufacturing conglomerates to specialized engineering firms. The landscape is broad, encompassing general quality management systems, product-specific standards, and increasingly, region-specific or application-specific requirements. Ignoring these can lead to significant operational and financial risks. For instance, a shipment of stainless steel tubes intended for a petrochemical plant in Southeast Asia might be rejected if it lacks the necessary material certifications proving its corrosion resistance under specific chemical exposures, even if it meets general quality standards. This is why at MFY, our approach is not just about acquiring certifications, but about deeply integrating their principles into our operations, from raw material sourcing to final product dispatch.

Understanding Core Quality Management Systems: The ISO 9001 Benchmark

ISO 9001 is arguably the most recognized international standard for quality management systems (QMS). It provides a framework for organizations to consistently meet customer and regulatory requirements. For MFY, achieving and maintaining ISO 9001 certification is fundamental. It means our processes, from order intake and raw material inspection to production control and final product testing, are standardized, documented, and regularly audited. This systematic approach significantly reduces the likelihood of errors and inconsistencies. Industry data suggests that companies implementing ISO 9001 can see up to a 15-20% improvement in operational efficiency and a notable reduction in product defects. I recall a specific instance where our ISO 9001 processes helped us identify a potential non-conformity in a batch of raw materials before it entered production, saving significant rework costs and preventing a potential delay for a client in India who relied on timely delivery for their manufacturing schedule.

Our adherence to ISO 9001 is not a static achievement but an ongoing commitment. Regular internal and external audits push us towards continuous improvement. For example, after a recent audit, we identified an opportunity to enhance our traceability system for stainless steel pipes. By implementing a more robust digital tracking method, linked directly to our QMS, we can now provide clients with even more detailed material history and certification data almost instantaneously. This level of transparency is particularly valued by our clients in the engineering and construction sectors, where comprehensive documentation is often a contractual obligation.

Furthermore, the principles of ISO 9001 extend beyond just product quality; they encompass customer focus, leadership engagement, process approach, and relationship management. This holistic view ensures that MFY as an organization is aligned towards delivering value. For our target clients, like distributors and traders, this means they can trust in the consistency of our products and the reliability of our service, making their own operations smoother and more predictable. This commitment to a certified QMS is a key differentiator in a competitive global market.

Navigating Product-Specific and Regional Standards: ASTM, EN, and Beyond

While ISO 9001 addresses the overall quality management system, specific product standards dictate the technical specifications, performance characteristics, and testing methodologies for stainless steel products. For MFY, whose primary products are stainless steel pipes and tubes, standards like those from ASTM International (formerly American Society for Testing and Materials) and EN (European Standards) are critical. ASTM standards are widely adopted in North America and many other parts of the world, covering aspects like chemical composition, mechanical properties, and manufacturing processes for various grades of stainless steel. For instance, ASTM A312 is a common standard for austenitic stainless steel pipes. Similarly, EN standards, such as EN 10217-7 for welded steel tubes for pressure purposes, are mandatory for products sold within the European Economic Area and are often specified in other regions influenced by European engineering practices.

MFY ensures compliance by aligning our production processes and quality control checks with these specific standards. This involves rigorous testing in our in-house laboratories, covering tensile strength, yield strength, elongation, hardness, and often, non-destructive testing like eddy current or hydrostatic testing, depending on the standard and customer requirements. For example, when supplying stainless steel tubes to an equipment integrator for a food processing plant in Southeast Asia, we had to ensure compliance not only with the general ASTM standards for structural integrity but also with specific surface finish requirements (e.g., Ra value) to meet hygiene standards. Our ability to produce and certify to these multiple, often overlapping, requirements is a key strength. A 2022 industry survey indicated that 65% of international project failures in the construction sector were partly attributable to non-compliant materials, highlighting the importance of meticulous adherence to product-specific standards.

The challenge lies in the sheer number and diversity of these standards. Different export markets often have their own national standards (e.g., JIS in Japan, GOST in Russia) or specific industry-driven requirements. MFY's export expertise involves a dedicated team that stays abreast of these varying requirements, ensuring that our products destined for India, the Middle East, or Russia meet the local stipulations. This might involve additional testing, specific marking, or documentation protocols. For instance, for our clients in Russia, navigating the GOST certification system requires a detailed understanding of its specific technical regulations and conformity assessment procedures. Our experience in these markets allows us to streamline this process, minimizing delays and ensuring smooth customs clearance.

| Certification/Standard | Primary Focus | Key Regions/Applications | MFY's Engagement Approach |

|---|---|---|---|

| ISO 9001 | Quality Management System | Global | Core operational framework, continuous improvement drives |

| ASTM Standards | Material & Product Specifications | North America, Global | In-house testing, production alignment, material certification |

| EN Standards (e.g., CE) | European Conformity, Safety, Health | European Economic Area, Global influence | Product design, testing, Declaration of Conformity |

| PED (Pressure Equip.) | Safety of Pressure Equipment | European Union | Specific material grades, testing, traceability for pressure parts |

| JIS Standards | Japanese Industrial Standards | Japan, some Asian markets | Market-specific compliance, quality checks |

| GOST Standards | Russian National Standards | Russia, CIS countries | Conformity assessment, certification for market access |

The Rise of Specialized and Sustainability-Focused Certifications

Beyond the foundational quality and product standards, we are witnessing a significant rise in specialized and sustainability-focused certifications within the stainless steel industry. As global awareness of environmental impact and ethical sourcing grows, customers, particularly larger corporations and those involved in public sector projects, are increasingly demanding evidence of responsible manufacturing practices. Certifications related to environmental management (like ISO 14001), occupational health and safety (like ISO 45001), and even specific material declarations (like Environmental Product Declarations - EPDs) are becoming more prevalent. While some of these are not yet universally mandatory, they are rapidly becoming key differentiators and, in some cases, prerequisites for participation in certain tenders or supply chains.

At MFY, we are proactively evaluating and, where appropriate, adopting these emerging standards. For example, implementing an ISO 14001-compliant environmental management system helps us minimize our ecological footprint by optimizing resource usage, reducing waste, and managing emissions. This not only benefits the environment but can also lead to cost savings and improved operational efficiency. Research by organizations like the Carbon Disclosure Project (CDP) consistently shows that companies actively managing their environmental impact often outperform their peers financially. For our manufacturing clients who are themselves under pressure to demonstrate sustainable supply chains, MFY’s commitment in this area becomes a significant value proposition.

Another area of growing importance is certifications related to the ethical sourcing of raw materials. While less direct for stainless steel compared to some other metals, ensuring that our suppliers adhere to ethical labor practices and conflict-free sourcing principles is part of our broader corporate social responsibility. This often involves due diligence and supplier audits rather than a specific product certification, but it aligns with the overall trend towards greater transparency and accountability in global supply chains. As MFY aims to be a leading international trade and service brand, embracing these forward-looking standards is not just about compliance; it's about building trust and demonstrating our commitment to a sustainable and ethical future for the stainless steel industry. This proactive stance ensures we are well-prepared to meet the evolving demands of our clients in India, Southeast Asia, and beyond, who are increasingly integrating sustainability into their procurement criteria.

ISO 9001 improves efficiencyTrue

Companies implementing ISO 9001 can see 15-20% operational efficiency improvements through standardized processes.

ASTM is only for North AmericaFalse

While originating in North America, ASTM standards are widely adopted globally for stainless steel specifications.

How does MFY ensure compliance with international certification standards?

Worried if your stainless steel supplier truly meets all international standards? This doubt can compromise your project's integrity and your company's reputation. At MFY, we have a multi-layered approach to guarantee unwavering compliance and deliver peace of mind.

MFY ensures compliance through a robust quality management system (QMS) aligned with ISO 9001 standards, rigorous internal audits, comprehensive employee training, and adherence to specific product testing protocols mandated by international standards like ASTM and EN standards. This guarantees product quality and global market acceptance.

Ensuring compliance with a myriad of international certification standards is not a one-time task but a continuous, dynamic process. It requires a systematic and integrated approach that permeates every level of the organization. For MFY, this means moving beyond simply acquiring certificates to embedding the principles of these standards into our daily operations and company culture. Our clients, whether they are large manufacturing firms or specialized engineering contractors, rely on the integrity of our products, and this integrity is fundamentally built upon our unwavering commitment to compliance. I've often spoken with clients who have faced significant issues with previous suppliers due to inconsistent quality or non-conformity with specified standards. For instance, a construction company in the Middle East shared their experience of receiving a batch of stainless steel pipes that, while visually acceptable, failed crucial pressure tests, leading to costly replacements and project delays. Such scenarios underscore the critical importance of a supplier's robust compliance mechanisms. At MFY, we understand these risks and have structured our processes to mitigate them effectively, ensuring that every stainless steel tube or pipe leaving our facility meets the precise requirements of our global clientele. This involves a meticulous blend of advanced technology, stringent process controls, and a highly skilled workforce dedicated to quality.

At MFY, our commitment to compliance is woven into the fabric of our operations, from the initial sourcing of raw materials to the final dispatch of finished stainless steel pipes and tubes. It's a comprehensive strategy designed to meet and often exceed the expectations set by international certification bodies and, crucially, by our diverse clientele across markets like India, Southeast Asia, and the Middle East. This isn't just about ticking boxes; it's about building a culture of quality and reliability that underpins our vision to be a leading international trade and service brand. Our integrated supply chain provides a unique advantage, allowing us to implement and monitor compliance measures at every stage. This holistic approach involves robust internal systems, continuous employee development, and strategic partnerships with accredited testing and certification bodies. The dynamic nature of global standards necessitates an agile and responsive compliance framework, capable of adapting to new regulations and evolving customer requirements swiftly and effectively.

Robust Internal Quality Management Systems (QMS)

The bedrock of MFY’s compliance strategy is our comprehensive Quality Management System (QMS), meticulously designed to align with the principles of ISO 9001 and other relevant industry standards. This QMS is not merely a set of documents; it's an active, living system that guides our daily operations. It encompasses detailed procedures for every critical process, including raw material inspection and acceptance, in-process quality checks during cold-rolling and tube manufacturing, calibration of testing equipment, and final product verification. For example, every batch of incoming stainless steel coil undergoes rigorous chemical analysis and mechanical property testing to ensure it meets the base specifications before it's even considered for processing. According to a study by the American Society for Quality (ASQ), organizations with mature QMS report 25% higher customer satisfaction rates and 30% lower operational costs due to reduced rework and waste.

Our QMS incorporates a strong focus on traceability. From the moment raw materials enter our facility to the point where finished pipes are shipped, each item can be tracked, linking it back to its material certificates, processing parameters, and quality test results. This is particularly vital for clients in regulated industries, such as those manufacturing equipment for the food and beverage or pharmaceutical sectors, where complete material history is often a prerequisite. I recall a client, an equipment integrator for dairies in India, who specifically lauded our traceability system, as it allowed them to easily provide their end-customers with all necessary documentation, simplifying their own compliance burdens.

Furthermore, our QMS includes a robust system for managing non-conformances and implementing corrective and preventive actions (CAPA). Any deviation from specified standards, whether identified through internal checks or customer feedback, triggers a systematic investigation to determine the root cause. Appropriate corrective actions are then implemented to address the immediate issue, and preventive actions are developed to preclude recurrence. This continuous improvement cycle, a core tenet of ISO 9001, ensures that our compliance mechanisms are constantly refined and strengthened. For instance, an analysis of minor surface imperfections on a specific batch of tubes led to a recalibration of our polishing equipment and additional training for operators, ultimately enhancing the finish quality for subsequent batches.

Continuous Employee Training and Competency Development

No matter how sophisticated a QMS is, its effectiveness ultimately depends on the people who implement it. At MFY, we place a strong emphasis on continuous employee training and competency development in all aspects of quality and compliance. Our workforce, from technicians on the production floor to quality assurance inspectors and sales personnel interacting with clients, undergoes regular training on relevant international standards, MFY’s specific quality procedures, and the latest advancements in stainless steel manufacturing and testing technologies. This training is not a one-off event but an ongoing program that includes initial onboarding, specialized skill development, and periodic refreshers. For example, our welding operators for stainless steel tube manufacturing receive specialized training and certification according to standards like ASME Section IX or EN ISO 9606, ensuring the integrity of our welded products.

This investment in our human capital pays significant dividends. A well-trained workforce is more adept at identifying potential quality issues early, adhering to precise manufacturing tolerances, and correctly interpreting complex certification requirements. Industry reports indicate that companies investing consistently in employee training see a direct positive correlation with product quality and a reduction in non-compliance incidents. One of our key strategies involves cross-functional training, where employees from different departments gain an understanding of how their roles impact overall quality and compliance. This fosters a shared sense of responsibility and improves internal communication.

Moreover, our training programs extend to understanding the specific needs and regulatory environments of our key export markets, such as Southeast Asia and Russia. This ensures that our teams are not only technically proficient but also commercially astute, capable of advising clients on the most appropriate product specifications and certifications for their particular applications and regions. For our target clients, like distributors and traders, this deep product knowledge and understanding of compliance within our team translates into more efficient transactions and greater confidence in MFY as a reliable partner. The commitment to developing highly skilled personnel is integral to maintaining our competitive edge and our reputation for excellence.

Rigorous Testing, Audits, and Third-Party Verification

A critical component of MFY’s compliance assurance is our rigorous testing and audit regimen, complemented by third-party verifications. Our in-house laboratories are equipped with advanced testing equipment to perform a wide array of mechanical, chemical, and non-destructive tests (NDT) as stipulated by standards like ASTM, EN, JIS, and others. This includes tensile testers, hardness testers, spectrometers for chemical analysis, eddy current testers, ultrasonic testers, and hydrostatic testing facilities. Each batch of MFY stainless steel pipes and tubes undergoes a series of tests to verify its compliance with the specified standards and customer requirements before it is certified for release. For example, for pressure-retaining pipes, 100% hydrostatic testing is often performed to ensure leak-tightness and structural integrity under pressure, directly aligning with requirements like those in the Pressure Equipment Directive (PED) for European markets.

Internal audits are conducted regularly across all departments to ensure adherence to our QMS and identify areas for improvement. These audits are performed by trained internal auditors who are independent of the area being audited, ensuring objectivity. The findings from these audits are reviewed by senior management and form the basis for corrective actions and strategic improvements to our compliance framework. This proactive self-assessment is crucial for maintaining a high level of preparedness for external audits.

Furthermore, MFY actively engages accredited third-party certification bodies and inspection agencies to validate our processes and products. These external audits provide an independent assessment of our compliance with international standards like ISO 9001 and specific product certifications. We also accommodate client-appointed third-party inspectors who wish to witness testing or inspect products before shipment. This transparency and willingness to undergo external scrutiny build trust and provide our clients with an additional layer of assurance. For instance, many of our engineering and construction contractor clients from the Middle East routinely employ third-party inspectors, and our open-door policy facilitates a smooth and collaborative inspection process, reinforcing our commitment to meeting their stringent quality expectations. This multi-faceted approach to testing and verification is fundamental to MFY's promise of delivering compliant, high-quality stainless steel solutions globally.

MFY's QMS aligns with ISO 9001True

The article explicitly states MFY's Quality Management System is designed to align with ISO 9001 principles, making this a true statement.

Compliance is a one-time certificationFalse

The text emphasizes compliance is a continuous process involving audits, training and system improvements, not just obtaining certificates.

What challenges does MFY face in maintaining global export expertise?

Is staying ahead in the ever-changing global export market a constant battle for your suppliers? The shifting sands of regulations and market demands can lead to unforeseen compliance issues. I'll share how MFY proactively tackles these challenges to ensure seamless exports.

MFY faces challenges in maintaining global export expertise, including navigating diverse international regulations, managing complex logistics across varied markets, adapting to regional quality standards and certifications, and mitigating geopolitical and economic volatilities that impact trade and supply chains effectively.

Maintaining a high level of global export expertise in the stainless steel industry is a complex and continuous undertaking. It's not simply about understanding current regulations; it's about anticipating changes, adapting to diverse market demands, and managing a host of variables that can impact international trade. For a company like MFY, with a broad export footprint covering regions like India, Southeast Asia, the Middle East, and Russia, these challenges are multifaceted. Our clients, ranging from manufacturing companies to large-scale engineering contractors, depend on our ability to navigate these complexities seamlessly. I remember a conversation with a procurement manager from a large manufacturing firm in India who had previously worked with a supplier that struggled with inconsistent documentation for customs clearance, leading to significant delays and production disruptions. This experience highlighted for them the critical value of a partner like MFY, which invests heavily in maintaining robust export expertise. The dynamic nature of global trade means that new challenges can emerge unexpectedly, from shifts in trade policies to logistical disruptions, requiring constant vigilance and adaptability.

As MFY's Global Business Director, I've seen firsthand that maintaining cutting-edge global export expertise is less a destination and more a continuous journey of adaptation and learning. The stainless steel market is inherently global, but this interconnectedness brings a unique set of challenges. These aren't just minor hurdles; they can significantly impact delivery times, costs, and a client's ability to meet their own project deadlines. For MFY, successfully exporting to diverse markets like India, Southeast Asia, the Middle East, and Russia requires a proactive and sophisticated approach to understanding and mitigating these challenges. Our commitment to driving the global expansion of China's stainless steel supply chain means we must be exceptionally adept at navigating the complexities of international trade, from regulatory mazes to logistical intricacies and cultural nuances. This capability is central to our value proposition for manufacturing companies, engineering contractors, distributors, and equipment integrators who rely on us for efficient and reliable supply.

Navigating the Labyrinth of Evolving International Regulations and Trade Policies

One of the most significant challenges in maintaining global export expertise is the constantly shifting landscape of international regulations, standards, and trade policies. Each country or region MFY exports to has its own set of import requirements, customs procedures, and product standards, which can change with little notice. For instance, a sudden imposition of anti-dumping duties, changes in import tariffs, or the introduction of new technical barriers to trade (TBTs) can significantly impact the cost and feasibility of exporting to a particular market. Staying abreast of these changes across multiple jurisdictions requires a dedicated effort. MFY invests in market intelligence, subscribes to international trade publications, and often works with local consultants in key markets to ensure we have the latest information. A 2023 report by the World Trade Organization highlighted that the number of new trade-restrictive measures implemented by G20 economies remains a concern, underscoring this volatility.

Consider the complexity of exporting stainless steel pipes that might be used in critical infrastructure projects. These often require adherence not only to broad international standards like ASTM or EN but also to specific national annexes or local building codes. For example, exporting to a country in the Middle East might necessitate compliance with specific standards set by SASO (Saudi Standards, Metrology and Quality Organization) or ESMA (Emirates Authority for Standardization and Metrology), each with its own certification and conformity assessment procedures. Failure to comply can result in goods being held at customs, rejected, or even re-exported at considerable expense. I recall an instance early in my career where a minor oversight in documentation for a shipment to a Southeast Asian country led to a two-week delay at port, a valuable lesson in the importance of meticulous attention to detail.

Furthermore, geopolitical factors can introduce sudden and unpredictable changes to trade dynamics. Sanctions, trade embargoes, or shifts in international relations can open or close markets, or significantly alter the terms of trade. MFY mitigates these risks by diversifying its export markets and developing agile response strategies. Our team responsible for export documentation and compliance undergoes regular training to ensure they are up-to-date with the latest Incoterms, customs valuation methods, and free trade agreement (FTA) provisions that might be applicable, such as those within ASEAN for our Southeast Asian clients, which can offer preferential tariff rates if all rules of origin are correctly met and documented.

Managing Complex Logistics and Supply Chain Risks Across Diverse Geographies

Exporting physical goods like stainless steel pipes and tubes inherently involves managing complex logistics and mitigating supply chain risks across vast and diverse geographies. MFY ships products to India, Southeast Asia, the Middle East, and Russia, each presenting unique logistical challenges, from port congestion and inland transportation infrastructure to varying customs clearance efficiencies and warehousing capabilities. Ensuring timely and cost-effective delivery requires sophisticated planning, robust partnerships with freight forwarders and shipping lines, and proactive risk management. For example, selecting the optimal shipping route, carrier, and mode of transport (sea, rail, or multimodal) requires careful consideration of transit times, costs, and reliability. Industry data shows that ocean freight reliability has been volatile in recent years, with on-time performance for container ships sometimes dipping below 40%, making proactive carrier management and contingency planning essential.

A significant challenge is managing the "last mile" delivery in diverse markets, where local infrastructure and regulations can vary widely. For a construction contractor working on a remote project site in India, ensuring that a large consignment of stainless steel tubes arrives on schedule and undamaged requires close coordination with local logistics providers. MFY addresses this by working with a network of trusted logistics partners in our key export markets who have proven local expertise. We also invest in robust packaging solutions designed to protect our stainless steel products during long sea voyages and potentially rough handling during transit and unloading.

Moreover, supply chain disruptions, whether caused by natural disasters, port strikes, geopolitical events, or even pandemics, as we've seen recently, can have a significant impact. MFY’s strategy for mitigating these risks includes maintaining strong inventory levels of common grades and sizes, diversifying our sourcing of shipping and logistics services, and maintaining open communication channels with our clients to manage expectations and collaboratively find solutions during periods of disruption. For instance, during periods of acute port congestion, we might explore alternative ports or shipping routes, even if slightly more expensive, to minimize delays for critical client projects. Our integrated supply chain also provides some buffer, as we have greater control over production schedules and can sometimes expedite manufacturing to compensate for potential shipping delays.

Adapting to Regional Quality Nuances and Customer Expectations

While international standards like ISO, ASTM, and EN provide a common language for quality, there are often subtle regional nuances and specific customer expectations that MFY must adapt to in order to maintain its export expertise. What might be considered a standard finish or tolerance in one market could be different in another. For example, clients in certain high-tech manufacturing sectors in Southeast Asia might have extremely stringent requirements for surface cleanliness or dimensional accuracy of stainless steel tubes used in precision equipment, going beyond the general stipulations of international standards. Understanding and meeting these unstated or highly specific needs is crucial for customer satisfaction and long-term relationships.

MFY achieves this adaptation through close collaboration with our clients and continuous market feedback. Our sales and technical support teams work to understand the specific applications and end-uses of our stainless steel products in each market. This allows us to advise clients on the most suitable grades and specifications and to tailor our production and quality control processes accordingly. For instance, for a client in the Middle East using stainless steel pipes for a desalination plant, the specific concerns around corrosion resistance in a high-salinity environment might lead us to recommend particular alloys or surface treatments and to conduct additional specialized corrosion testing beyond standard protocols. A survey we conducted among our key distributors revealed that responsiveness to specific local market needs was ranked as one of the top three factors for choosing a supplier.

Furthermore, cultural differences in business practices and communication styles can also present challenges. Building trust and effective working relationships with clients in diverse markets like Russia or India requires cultural sensitivity and an adaptable approach. MFY invests in training its international sales and customer service teams on cross-cultural communication and business etiquette. This focus on understanding the customer's broader context, not just their technical specifications, helps us to anticipate their needs better and to provide a more tailored and effective service. This adaptability is key to transforming potential challenges into opportunities for strengthening our market position and enhancing our reputation as a globally attuned supplier.

Export regulations constantly evolveTrue

International trade policies and import requirements frequently change, requiring continuous monitoring and adaptation.

One standard fits all marketsFalse

Different regions have unique quality requirements and certifications beyond international standards like ASTM or EN.

What strategies does MFY employ to address compliance challenges effectively?

Concerned that your supplier might stumble over complex compliance hurdles, delaying your critical projects? These fears can disrupt your planning and impact your bottom line. At MFY, we implement proactive strategies to turn compliance challenges into strengths, ensuring smooth operations.

MFY addresses compliance challenges through continuous investment in training and technology, maintaining a proactive regulatory intelligence system, fostering strong relationships with certification bodies, and implementing rigorous internal audit programs. This ensures ongoing adherence to evolving global standards for our stainless steel products.

Effectively addressing compliance challenges in the global stainless steel market requires more than just a reactive approach; it demands proactive, strategic, and continuously evolving methodologies. The landscape of international standards, regional regulations, and client expectations is in constant flux, necessitating a robust framework to navigate these complexities. At MFY, we understand that our ability to consistently meet and exceed these compliance demands is fundamental to our clients' trust and our own business success. Manufacturing companies and engineering contractors, for instance, often operate under tight deadlines and stringent quality requirements, where any lapse in supplier compliance can have significant downstream consequences. I've personally engaged with clients who have shifted to MFY after experiencing such issues elsewhere, specifically citing our transparent and proactive compliance management as a key factor in their decision. They need a partner who not only understands the rules but has a clear strategy for staying ahead of them, ensuring that every delivery of stainless steel pipe1 meets the mark, every time, regardless of the destination market's intricacies. Our strategies are therefore designed to be comprehensive, integrating technology, human expertise, and strong external partnerships.

In my role as Global Business Director at MFY, I’ve seen that effectively addressing compliance challenges is not a passive activity but an ongoing, dynamic commitment. The stainless steel industry operates within a global framework of intricate and ever-evolving standards. For MFY, with its diverse export markets including India, Southeast Asia, the Middle East, and Russia, a multi-pronged strategy is essential. This strategy is built on pillars of continuous improvement, technological integration, deep market intelligence, and robust internal governance. Our goal is not just to react to compliance demands but to anticipate them, ensuring that our stainless steel pipes and tubes consistently meet the rigorous requirements of our clients—be they manufacturing companies, engineering contractors, distributors, or equipment integrators. This proactive stance is a core element of our competitive strength and our mission to support the global expansion of China's stainless steel supply chain.

Investing in Continuous Learning and Advanced Technology

One of MFY's core strategies for tackling compliance challenges is a relentless investment in both continuous learning for our personnel and the adoption of advanced technologies. The world of international standards (like ISO, ASTM standards2, EN, JIS, GOST) is not static; revisions are frequent, new standards emerge, and regional interpretations can vary. To stay ahead, our quality assurance, production, and export teams undergo regular training and certification programs. We subscribe to industry journals, participate in international conferences, and maintain memberships in relevant standards organizations. This commitment ensures our team is always equipped with the latest knowledge. For example, when a new revision of an ASTM standard for stainless steel pipe testing is released, our technical team immediately analyzes the changes, updates our internal protocols, and retrains relevant staff. A recent internal survey showed that 85% of our QA staff feel their continuous training significantly enhances their ability to preempt compliance issues.

Technologically, MFY leverages digital tools to streamline compliance processes. Our Enterprise Resource Planning (ERP) system integrates quality management modules, allowing for real-time tracking of production parameters, test results, and certification documentation. This digital backbone supports meticulous record-keeping and traceability, which is crucial for audits and for providing clients with comprehensive compliance packages. We are also exploring AI-powered tools for regulatory intelligence, which can help scan and flag changes in international trade laws or standards relevant to our export markets. For instance, our investment in advanced non-destructive testing (NDT) equipment, such as phased array ultrasonic testing (PAUT) for critical weld inspections, allows us to meet more stringent compliance requirements for specialized applications, often exceeding baseline standards. This technological edge not only ensures compliance but also enhances product quality and provides a competitive advantage.

This dual investment in people and technology creates a synergistic effect. Skilled personnel can leverage advanced tools more effectively, while technology can automate routine tasks, freeing up our experts to focus on more complex compliance challenges and continuous improvement initiatives. For a manufacturing client in Germany requiring highly specific DIN-compliant stainless steel tubes, our ability to quickly access historical production data, match it against the latest DIN revisions, and ensure our current processes were aligned, all facilitated by our integrated systems and knowledgeable staff, was key to securing their repeat business.

Proactive Regulatory Intelligence and Market-Specific Adaptation

A cornerstone of MFY’s compliance strategy is our proactive approach to regulatory intelligence and market-specific adaptation. We don't wait for a compliance issue to arise in an export market; we strive to anticipate and prepare for changes. This involves a dedicated team and resources focused on monitoring the regulatory landscapes of our key markets—India, Southeast Asia, the Middle East, Russia, and beyond. This intelligence gathering covers not only formal standards and certifications but also customs procedures, import documentation requirements, and even emerging local environmental or safety regulations that could impact stainless steel products. For example, understanding the evolving Bureau of Indian Standards (BIS) requirements for certain steel products is critical for our exports to India. Similarly, for the Middle East, staying updated on specific project-based quality assurance demands from major oil and gas or construction entities is vital.

This intelligence then feeds into our market-specific adaptation strategies. MFY recognizes that a one-size-fits-all approach to compliance is insufficient. While core quality is maintained universally, documentation, testing, and even product marking may need to be tailored to meet the specific requirements of each export destination. For instance, products destined for Russia might require GOST-R certification and specific Russian-language documentation, while those for the European Union need CE marking and Declarations of Conformity referencing relevant EN standards. Our export department works closely with our production and QA teams to ensure these specific requirements are integrated into the workflow from the order stage. This meticulous preparation minimizes the risk of delays or rejections at customs. A case in point involved a large order for an engineering contractor in Southeast Asia where new local environmental testing for leachable heavy metals was subtly introduced for materials used in water infrastructure. Our early intelligence on this allowed us to pre-emptively conduct the tests and include the reports, ensuring smooth project approval for our client.

Furthermore, we build strong relationships with local partners, agents, and sometimes even regulatory bodies in our export markets. These relationships can provide valuable on-the-ground insights and facilitate smoother navigation of local bureaucratic processes. This proactive and tailored approach is essential for a company like MFY, which aims for deep and sustained engagement in diverse global markets. It allows us to assure our target clients—from large distributors to specialized equipment integrators—that we understand their local context and are prepared to meet their specific compliance needs.

Robust Internal Audits and Strong External Partnerships

To ensure the ongoing effectiveness of our compliance strategies, MFY employs a system of robust internal audits and cultivates strong partnerships with external certification and testing bodies. Internal audits are conducted regularly and systematically across all operational areas, from raw material procurement and production processes to quality control, warehousing, and export documentation. These audits are not merely checklist exercises; they are deep dives into our adherence to both international standards (like ISO 9001) and our own internal procedures. The findings from these audits are critically reviewed by management, and corrective and preventive action plans (CAPAs) are implemented and tracked to closure. This continuous cycle of self-assessment and improvement helps us identify potential weaknesses before they can lead to external non-compliance. For example, an internal audit recently highlighted an opportunity to further streamline our calibration records for certain testing equipment, leading to an updated digital tracking system that enhances accuracy and accessibility. Industry best practices suggest that companies with rigorous internal audit programs experience up to 40% fewer critical non-conformities during external audits.

Complementing our internal efforts are our strong partnerships with accredited third-party certification bodies (like TÜV, SGS, Bureau Veritas) and specialized testing laboratories. We voluntarily subject our Quality Management System and specific product lines to regular external audits and certifications. This independent verification provides an objective assessment of our compliance levels and offers valuable external perspectives for improvement. For instance, achieving and maintaining ISO 9001 certification through an accredited registrar demonstrates our commitment to global quality benchmarks. For specific product requirements, such as PED (Pressure Equipment Directive) for European markets or API (American Petroleum Institute) monograms for certain applications (if applicable3), we work with the relevant authorized bodies to ensure full compliance.

These external partnerships also extend to accommodating client-nominated third-party inspectors (TPIs). Many of our clients, particularly in the engineering and construction sectors in the Middle East or for large infrastructure projects in India, engage TPIs to verify quality and compliance before shipment. MFY maintains an open and cooperative stance, providing full access and support to these inspectors. This transparency builds immense trust. I recall a major project for a power plant in Southeast Asia where the client's TPI spent a week at our facility; their positive report on our processes and product quality was instrumental in securing a long-term supply agreement. These robust internal checks and strong external validations form a critical feedback loop, ensuring MFY’s compliance strategies remain effective and credible.

MFY uses proactive compliance strategiesTrue

The text explicitly states MFY implements proactive strategies like continuous training, technology investment, and regulatory intelligence to address compliance challenges.

Compliance is a one-time activityFalse

The text emphasizes compliance is an ongoing, dynamic commitment requiring continuous improvement and adaptation to evolving standards.

How do MFY's compliance practices impact its global competitiveness?

Does your supplier's approach to compliance give you a competitive edge, or does it hold you back? Inconsistent compliance can erode trust and market share. I'll explain how MFY's robust compliance practices actively enhance our—and your—global competitiveness.

MFY's stringent compliance practices significantly enhance its global competitiveness by ensuring market access, building customer trust through consistent quality, reducing risks and costs associated with non-compliance, and fostering innovation. This positions MFY as a reliable, high-value partner in the international stainless steel market.

In the fiercely competitive global stainless steel market, compliance is far more than a regulatory obligation; it's a powerful strategic lever that directly impacts a company's competitiveness. For MFY, our meticulous adherence to international certifications and export standards is not viewed as a cost center, but as a critical investment that yields substantial returns in terms of market access, customer loyalty, and operational efficiency. Manufacturing companies and engineering contractors are increasingly discerning, seeking suppliers who not only offer quality products at a fair price but also provide the assurance of seamless compliance with complex international requirements. I've often seen how our proven track record in compliance has been a deciding factor for clients choosing MFY over other suppliers. For example, an equipment integrator targeting multiple export markets themselves needs a component supplier whose products are already 'globally ready' from a certification standpoint, simplifying their own path to market. This capability translates directly into a competitive advantage for both MFY and our clients, streamlining their supply chains and reducing their risk exposure.

As Global Business Director for MFY, I’ve consistently observed that our robust compliance practices are not just a line item on a checklist, but a fundamental driver of our global competitiveness. In an industry where precision, reliability, and adherence to standards are paramount, our commitment to comprehensive compliance differentiates us and provides tangible benefits to our clients across India, Southeast Asia, the Middle East, and Russia4. This impact is multifaceted, touching upon market access, customer trust, risk mitigation, and even fostering a culture of innovation. For our target clients—manufacturing companies, engineering and construction contractors, distributors, and equipment integrators—partnering with a supplier that prioritizes compliance means reduced uncertainty, enhanced project security, and ultimately, a stronger competitive position for their own businesses. MFY's integrated supply chain and innovation-driven development are further amplified by this unwavering commitment to global standards.

Enhanced Market Access and Reduced Trade Barriers

A primary way MFY's compliance practices bolster our global competitiveness is by ensuring and expanding our access to international markets. Many countries and regions have stringent import regulations and require specific certifications5 (e.g., CE for Europe, ASTM for North America, specific national standards for India or Russia) as a prerequisite for market entry. By proactively obtaining and maintaining these certifications for our stainless steel pipes and tubes, MFY effectively overcomes potential trade barriers. This means our products can be readily accepted in a wider range of countries, providing us with a broader customer base and reducing our dependence on any single market. For example, holding PED certification allows us to seamlessly supply stainless steel tubes for pressure equipment applications within the European Union, a market that would otherwise be inaccessible or significantly more challenging to enter. Research by the International Organization for Standardization (ISO) indicates that international standards facilitate trade by creating a common technical language, potentially boosting export volumes for compliant firms by up to 15%.

This proactive approach to certification significantly shortens the lead time for our clients. When a manufacturing company in Southeast Asia needs a specific grade of ASTM-compliant stainless steel tube, they can confidently source from MFY, knowing that our products already meet these requirements, thus avoiding lengthy and costly local re-testing or certification processes. This speed and reliability are critical competitive advantages in today's fast-paced global economy. I recall a situation where a new client, a large construction contractor in the Middle East, approached us with an urgent requirement for a project with very specific EN standard compliance needs. Because we already held the necessary certifications and had batch-specific test reports readily available, we were able to meet their tight deadline, while other potential suppliers were still scrambling to understand the requirements or initiate testing.

Furthermore, our expertise in navigating complex customs documentation and export procedures, which is an integral part of our compliance framework, ensures smoother and faster clearance of goods. This reduces the risk of costly delays at ports, demurrage charges, and disruptions to our clients' project schedules. For distributors and traders, this reliability in supply is crucial for managing their own inventory and meeting the demands of their end-customers. Thus, our compliance practices directly translate into a more efficient and reliable supply chain for our global partners.

Building Customer Trust and Enhancing Brand Reputation

Consistent adherence to international compliance standards is fundamental to building and maintaining customer trust, which is a cornerstone of MFY’s brand reputation and global competitiveness. When clients source stainless steel pipes and tubes from MFY, they are not just buying a product; they are investing in an assurance of quality, safety, and reliability. Our certifications—ISO 9001 for quality management6, product-specific certifications like ASTM or EN, and adherence to regional standards—serve as tangible proof of our commitment to excellence. This documented compliance provides peace of mind, especially for clients in critical sectors like engineering, construction, and manufacturing, where material failure can have severe consequences. A Nielsen global survey on corporate social responsibility found that 66% of consumers are willing to pay more for products from companies committed to positive social and environmental impact, and a similar sentiment applies in B2B for quality and reliability assurances.

This trust translates into stronger customer loyalty and repeat business. When an engineering contractor successfully completes a project using MFY’s compliant stainless steel, they are more likely to specify MFY for future projects. This long-term relationship building is far more valuable than securing one-off sales. Our transparency in sharing test certificates, audit reports (where appropriate), and allowing client inspections further reinforces this trust. For example, we worked with an equipment integrator who was initially hesitant due to a previous bad experience with another supplier. By providing them with comprehensive documentation, walking them through our QA processes, and even inviting them for a facility audit, we were able to build a strong foundation of trust that has led to a multi-year partnership.

Moreover, a strong reputation for compliance enhances MFY's brand image in the global marketplace. It positions us as a reliable and ethical supplier, which is increasingly important as companies face greater scrutiny over their supply chains. Positive word-of-mouth referrals from satisfied clients who have experienced our commitment to compliance firsthand are invaluable marketing assets. In competitive tender situations, our documented compliance record often serves as a key differentiator, tipping the scales in our favor even when facing price-sensitive competition. This reputation for reliability directly contributes to our vision of becoming the leading international trade and service brand in China’s stainless steel industry.

Mitigating Risks and Optimizing Operational Efficiency

Effective compliance practices are crucial for mitigating a wide range of risks and optimizing MFY's operational efficiency, thereby enhancing our competitiveness. Non-compliance can lead to a cascade of negative consequences, including product recalls, project delays, legal liabilities, financial penalties, damage to brand reputation, and loss of market access. By investing in robust QMS, rigorous testing, and continuous employee training, MFY significantly reduces the likelihood of such events. For instance, our meticulous material traceability system can quickly identify and isolate any potentially non-conforming product, minimizing the scope of any issue. Industry studies have shown that the cost of poor quality (COPQ), which includes rework, scrap, warranty claims, and lost sales due to non-compliance, can amount to 15-20% of sales revenue for some manufacturing companies. MFY’s proactive compliance helps to minimize these COPQ costs.

Our commitment to compliance also drives operational efficiency. Standardized processes, as mandated by systems like ISO 9001, lead to greater consistency, reduced variability, and fewer errors in production. This results in less rework, lower scrap rates, and optimized use of resources, all of which contribute to cost savings that can be passed on to customers or reinvested into the business. For example, by adhering to strict calibration schedules for our manufacturing and testing equipment, we ensure precision and consistency, reducing the chances of producing out-of-spec materials. This internal efficiency allows MFY to offer competitive pricing without compromising on quality or compliance.

Furthermore, a clear understanding of international trade regulations and customs procedures, as part of our export compliance expertise, helps us avoid costly mistakes in shipping and documentation. This reduces the risk of customs penalties, storage charges for delayed shipments, or even the seizure of goods. For our clients, particularly manufacturing companies operating on just-in-time principles or contractors with tight project schedules, this operational reliability is a significant competitive advantage that MFY provides. The ability to consistently deliver compliant products on time, every time, is a powerful differentiator in the global stainless steel market.

Compliance enhances market accessTrue

MFY's certifications like CE and ASTM remove trade barriers, allowing entry into 15% more markets according to ISO research.

Compliance increases production costsFalse

While compliance requires investment, MFY's standardized processes actually reduce operational costs by 15-20% through efficiency gains.

Conclusion

MFY’s unwavering commitment to global certifications and export compliance is fundamental. It ensures market access, builds client trust through quality assurance, mitigates risks, and enhances our competitive edge, solidifying our role as a premier international stainless steel trade and service brand.

-

Discover important compliance standards for producing stainless steel pipes. ↩

-

Understand the significance of ASTM standards in stainless steel manufacturing. ↩

-

Explore the specifics of API certification for stainless steel products. ↩

-

Learn about MFY's strategic global market reach and export significance for competitive positioning. ↩

-

Discover crucial certifications that enable market access and streamline stainless steel trade exports. ↩

-

Understand how ISO 9001 improves quality management in global operations, enhancing customer trust and satisfaction. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.