Schedule 40 vs Schedule 80: How to Choose Wall Thickness

Are you struggling to decide between Schedule 40 and Schedule 80 pipes for your project? The wrong choice can lead to catastrophic system failures or unnecessary budget overruns. At MFY, we guide our clients through this critical decision to ensure both safety and cost-effectiveness.

The primary difference between Schedule 40 and Schedule 80 pipe is the wall thickness. For a given nominal pipe size, Schedule 80 pipe has a thicker wall, a smaller inside diameter, a higher weight, and a significantly higher pressure rating compared to Schedule 40 pipe.

Choosing the right pipe schedule is a foundational decision that impacts your project's longevity, safety, and budget. It's a choice that extends beyond a simple price comparison, touching on critical performance metrics and operational resilience. Let's explore the nuances to ensure you make an informed decision that aligns with your specific application needs.

In my role as Global Business Director at MFY, I've seen firsthand how a seemingly small detail like pipe wall thickness can have massive implications. A client in the Middle East, an engineering contractor, once considered using Schedule 40 for a high-pressure chemical processing line to reduce initial costs. However, a thorough analysis of their operational pressures and safety requirements revealed this would be a critical mistake. By guiding them to Schedule 80, we helped them avert potential leaks and costly downtime. This isn't just about selling a product; it's about engineering a reliable and safe solution. The choice between these two schedules is a masterclass in balancing performance, risk, and financial investment, a balance we help our partners strike every day.

What are the key differences between Schedule 40 and Schedule 80 pipes?

Selecting the correct pipe schedule feels like a minor detail, but it's a critical decision that can define your project's success. An incorrect choice can lead to budget blowouts from over-engineering or, worse, catastrophic failures. We'll help you understand the core differences to make the right call.

The key differences lie in wall thickness, inside diameter, weight, and pressure capacity. Schedule 80 pipes feature a thicker wall, resulting in a smaller internal bore but a much higher pressure rating (PSI) than Schedule 40 pipes of the same nominal size.

These distinctions, while seemingly straightforward, create a ripple effect that influences everything from system design and structural support requirements to the overall project budget and long-term operational safety. For instance, while Schedule 40 might be perfectly suitable for low-pressure water distribution, it would be dangerously inadequate for high-pressure steam or hydraulic lines where Schedule 80 is the industry standard. I often consult with manufacturing clients in Southeast Asia who are scaling up their production facilities. Their initial instinct is sometimes to standardize on one schedule to simplify inventory. However, a detailed application review often reveals that a hybrid approach—using Schedule 40 for general fluid transfer and Schedule 80 for more demanding processes—delivers the optimal balance of safety and cost-efficiency. This nuanced understanding is what separates a standard supply chain from a truly optimized one. It’s about more than just delivering stainless steel pipes; it’s about delivering a solution that is both technically sound and commercially astute. At MFY, our integrated supply chain allows us to provide this level of detailed consultation, ensuring our clients receive not just a product, but a competitive advantage.

The decision-making process requires a deep dive into the technical specifications and their real-world implications. It’s a conversation that moves beyond the datasheet and into the heart of your operational environment. Factors like fluid characteristics, operating temperature, external loads, and regulatory compliance all play a pivotal role. The choice is not merely a matter of selecting the "stronger" option; it's about selecting the appropriate option. Over-specifying with Schedule 80 where it isn't needed can lead to unnecessarily high material costs, increased weight (requiring more robust structural supports), and higher labor costs for welding and handling. Conversely, under-specifying with Schedule 40 in a high-stress environment is a direct risk to asset integrity and personnel safety. This is why a collaborative approach with a knowledgeable supplier is invaluable. We bring our cross-industry experience to the table, helping you navigate these complexities and make a choice that guarantees performance, safety, and value for the long term.

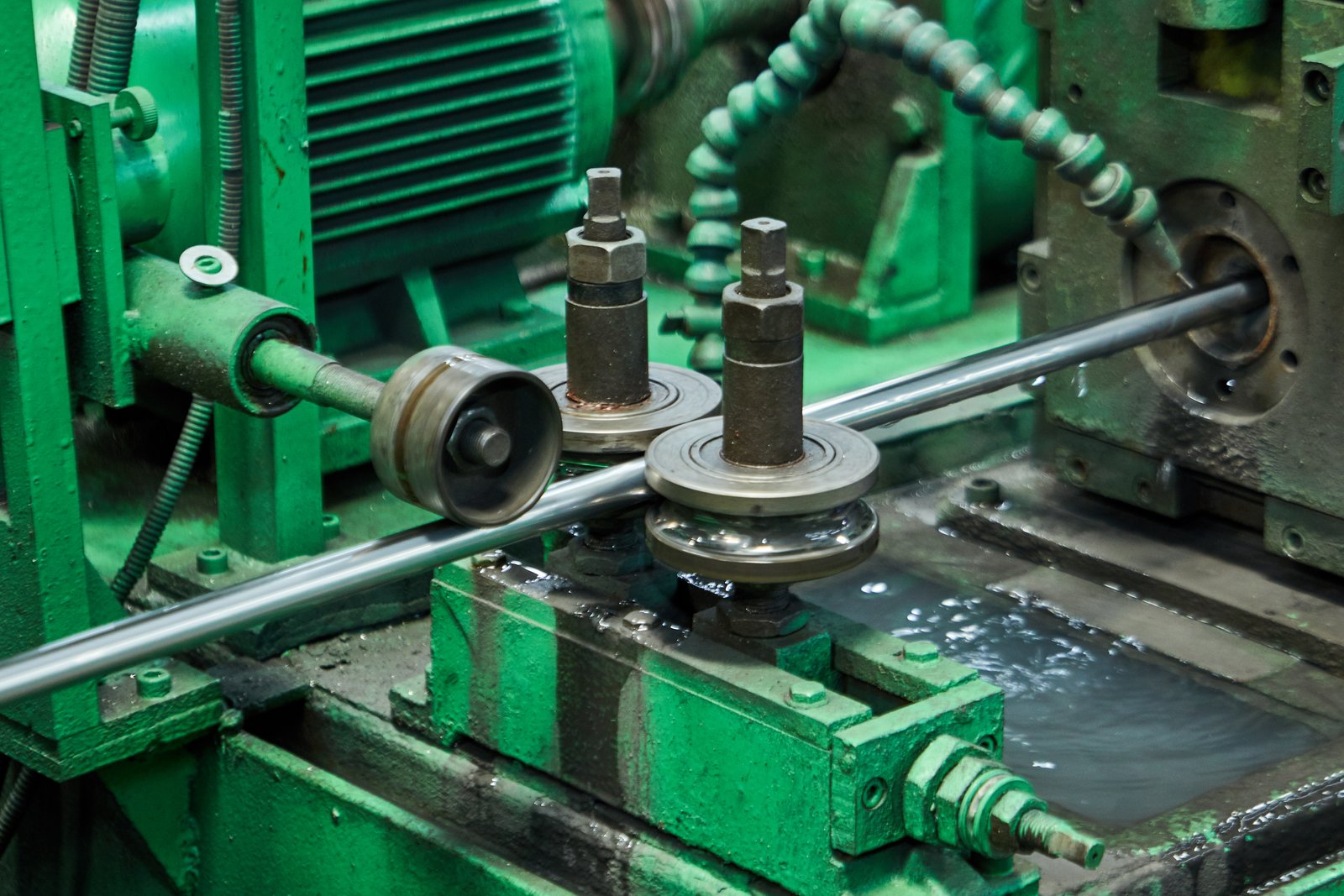

Unpacking the Core Physical Distinctions

The most fundamental difference between Schedule 40 (SCH 40) and Schedule 80 (SCH 80) stainless steel pipe is wall thickness. For any given Nominal Pipe Size (NPS), the outside diameter (OD) remains constant to ensure standardization of fittings and valves. The variation comes from the inside diameter (ID). A SCH 80 pipe has a thicker wall, which means its ID is smaller than that of a SCH 40 pipe of the same NPS. This directly impacts the pipe's internal volume and flow rate characteristics.

This physical variance in wall thickness has a direct correlation with the pipe's weight and, consequently, its cost. The additional material in a SCH 80 pipe makes it heavier per foot and more expensive. For large-scale projects, like those managed by engineering and construction contractors we partner with in India, this cost difference can be substantial. For example, a 4-inch NPS SCH 80 pipe can be over 40% heavier than its SCH 40 counterpart, which not only increases the raw material cost but also impacts logistics, handling, and the structural engineering of the pipe supports.

Furthermore, the thicker wall of SCH 80 pipe provides greater structural rigidity and resistance to corrosion. While the material grade (e.g., 304L or 316L stainless steel) dictates the inherent corrosion resistance, a thicker wall provides a larger buffer against wall loss over time, especially in abrasive or erosive service conditions. I recall a case with an equipment integrator building desalination skids for a Middle Eastern client. They opted for SCH 80 316L pipes not just for the pressure rating, but for the enhanced lifespan in the highly corrosive high-salinity water environment, justifying the higher initial investment with a lower total cost of ownership.

The Critical Role of Pressure Rating (MAOP)

The single most important performance differentiator derived from wall thickness is the Maximum Allowable Operating Pressure (MAOP). The thicker wall of a SCH 80 pipe gives it a significantly higher pressure rating than a SCH 40 pipe. This is a non-negotiable factor in system design. The pressure capacity is calculated using Barlow's formula, which directly links allowable pressure to the pipe's material strength1 (tensile strength), outside diameter, and wall thickness. A thicker wall means the pipe can safely contain higher internal pressures.

To illustrate, let's consider a common 2-inch NPS stainless steel pipe. A typical SCH 40 pipe might have a pressure rating of around 1,500 PSI at ambient temperature, whereas a SCH 80 pipe of the same size could be rated for over 2,000 PSI. This difference is critical for applications such as hydraulic systems, high-pressure chemical injection lines, or steam distribution networks where pressures routinely exceed the safe limits of SCH 40. A manufacturing client in Vietnam was designing a new production line involving high-pressure fluid transfer. Their initial design mistakenly specified SCH 40. During our supply consultation, we flagged this as a major safety risk. By providing them with the clear pressure rating data and application norms, they revised the specification to SCH 80, ensuring the safety and integrity of their new facility.

The table below provides a clear comparison for A312 seamless stainless steel pipe at ambient temperature, demonstrating how pressure ratings scale with schedule and size. Note how the pressure advantage of SCH 80 becomes even more pronounced as the pipe diameter increases, as the wall stress is distributed over a larger area. This data is fundamental to the work of any engineer or contractor designing a pressurized system.

| Nominal Pipe Size (NPS) | Schedule | Wall Thickness (in) | Inside Diameter (in) | Max Pressure (PSI) - Approx. |

|---|---|---|---|---|

| 2" | SCH 40 | 0.154 | 2.067 | 1,510 |

| 2" | SCH 80 | 0.218 | 1.939 | 2,140 |

| 4" | SCH 40 | 0.237 | 4.026 | 1,210 |

| 4" | SCH 80 | 0.337 | 3.826 | 1,740 |

| 6" | SCH 40 | 0.280 | 6.065 | 970 |

| 6" | SCH 80 | 0.432 | 5.761 | 1,520 |

Implications for Flow and System Design

The difference in inside diameter between the two schedules has a significant impact on fluid dynamics. Because SCH 80 pipe has a smaller bore, it creates a smaller cross-sectional area for flow. For a given flow rate, this results in higher fluid velocity compared to a SCH 40 pipe of the same NPS. Higher velocity can lead to increased frictional pressure loss over the length of the pipeline, which may require more powerful pumps and consume more energy.

This trade-off is a crucial consideration for distributors and traders advising their customers. A project might require the pressure handling of SCH 80, but the system designer must account for the reduced flow area. In some cases, to achieve a desired flow rate without excessive pressure drop, it might be necessary to step up to the next nominal pipe size in SCH 80, which further impacts the project's overall cost and footprint. For example, if a system designed with 4-inch SCH 40 pipe is upgraded to SCH 80 for pressure reasons, the engineer must recalculate the head loss to ensure the existing pump specifications are still adequate.

At MFY, our role often extends beyond simple supply. With our integrated production and technical sales teams, we help clients model these scenarios. For a large-scale water treatment facility in Southeast Asia, we worked with the contractor to analyze flow rates and pressure requirements across their entire system. We identified that while main distribution lines could use cost-effective SCH 40, the high-pressure reverse osmosis sections absolutely required SCH 80. This detailed analysis, supported by our robust inventory and rapid export delivery, allowed them to optimize their design for both performance and budget, avoiding costly redesigns and operational issues down the line.

Schedule 80 has thicker walls than Schedule 40Правда

The primary difference between these pipe schedules is wall thickness, with Schedule 80 having approximately 30-50% thicker walls for the same nominal size.

Schedule 40 has higher pressure ratingsЛожь

Schedule 80 pipes actually have significantly higher pressure ratings (MAOP) due to their thicker walls, making them suitable for high-pressure applications.

How does the wall thickness of Schedule 40 and Schedule 80 affect performance?

You're worried that choosing a pipe based only on cost could compromise safety and operational efficiency. Skimping on wall thickness can lead to premature failure under pressure, while over-specifying wastes capital. Let us guide you to the right balance for peak performance and peace of mind.

Wall thickness is the primary determinant of a pipe's pressure rating and structural strength. The thicker wall of Schedule 80 pipe provides superior pressure containment, greater rigidity against external loads and vibration, and a longer lifespan in corrosive or erosive environments compared to Schedule 40.

This crucial physical attribute directly dictates the applications for which each schedule is suitable. The decision impacts not only the safety and reliability of your piping system but also its hydraulic characteristics and installation requirements. For example, I recently worked with an equipment integrator for the oil and gas sector2. Their skids required high structural integrity to withstand vibration during operation and transport. While the internal pressure was manageable by Schedule 40, they strategically chose Schedule 80 for its superior rigidity and durability, ensuring the long-term reliability of their equipment in a demanding field environment. This foresight, which considers performance beyond just internal pressure, is a hallmark of robust engineering. At MFY, we champion this holistic view, leveraging our deep industry knowledge to help clients see the full performance picture. Our goal is to ensure the stainless steel pipe you choose contributes positively to every aspect of your project, from initial installation to long-term maintenance.

The performance implications extend into the very fabric of your project's design and execution. A heavier pipe, like Schedule 80, demands more substantial support structures and hangers, adding to the overall structural load and material cost. The welding process also differs; the thicker wall of Schedule 80 requires more preparation, more welding passes, and consequently, higher labor costs and time on site. Furthermore, the smaller internal diameter of Schedule 80 affects fluid dynamics, increasing velocity and friction loss for a given flow rate, which might necessitate adjustments in pump sizing and energy consumption calculations. We once assisted a construction contractor in Russia3 with a district heating project. They had to balance the need for Schedule 80's strength in high-stress zones with the hydraulic efficiency and lower cost of Schedule 40 in less critical areas. By leveraging MFY’s diverse inventory and integrated supply chain, we delivered a precisely tailored package of both schedules, optimizing their project for both performance and cost. This is the kind of practical, value-driven partnership we strive for.

Pressure Containment and Safety Margins

The most direct impact of wall thickness is on pressure containment. As established, Schedule 80's thicker wall allows it to safely handle significantly higher internal pressures than Schedule 40. This isn't just a matter of meeting the minimum required pressure rating; it's also about incorporating a sufficient safety margin. In industrial applications, systems can experience pressure surges, spikes, or water hammer effects that temporarily exceed the normal operating pressure. The additional material in a Schedule 80 pipe provides a much larger buffer against these transient events, preventing catastrophic failure.

For manufacturing companies dealing with volatile or hazardous fluids, this safety margin is paramount. A leak or rupture in a chemical or high-temperature steam line can have devastating consequences for personnel, equipment, and the environment. Therefore, even if the standard operating pressure is technically within the limits of Schedule 40, industry best practices and internal safety standards often mandate the use of Schedule 80. A client of ours, a specialty chemical manufacturer, has a strict policy of using Schedule 80 for all process piping, regardless of pressure. This policy simplifies their engineering standards, reduces the risk of misapplication, and provides an enhanced safety factor that aligns with their corporate commitment to operational safety.

This principle is enshrined in engineering codes like ASME B31.1 for Power Piping and B31.3 for Process Piping. These codes provide rigorous formulas for calculating the required wall thickness based on design pressure, temperature, material properties, and corrosion allowance. In almost all high-pressure or high-temperature scenarios, these calculations will point directly to the necessity of using Schedule 80 or even heavier-walled pipes. The choice is less of a preference and more of a requirement dictated by sound engineering principles and regulatory compliance.

Structural Integrity and External Load Resistance

Performance isn't solely about internal pressure. Pipes are structural members that must withstand external forces, including the weight of the pipe and its contents, thermal expansion/contraction stresses, and external pressures (like in buried or subsea applications). The thicker wall and greater cross-sectional area of Schedule 80 pipe give it a higher moment of inertia, making it significantly more rigid and resistant to bending and deflection.

This is a critical factor for long pipe runs between supports. Using a more rigid Schedule 80 pipe can allow for wider spacing between pipe hangers and supports, which can sometimes offset the higher material cost by reducing the number of supports and the associated installation labor. More importantly, in environments with significant vibration from pumps, compressors, or other machinery, the enhanced stiffness of Schedule 80 helps to dampen vibration and reduce the risk of fatigue failure at joints and connection points. An engineering contractor we worked with on a power generation project chose Schedule 80 for all auxiliary steam and condensate lines for this very reason. The added stiffness was essential to ensure the piping system's longevity amidst the constant vibration of the turbine hall.

Furthermore, in applications where the pipe might be exposed to mechanical impact, such as in high-traffic plant areas or on mobile equipment skids, the thicker wall of Schedule 80 provides superior impact resistance. It offers an extra layer of physical protection against accidental damage that could compromise a thinner-walled Schedule 40 pipe. This robustness is a key performance attribute that contributes directly to the overall reliability and resilience of the facility.

Corrosion Allowance and Flow Characteristics

In systems where corrosion or erosion are expected, wall thickness plays a crucial role in the pipe's service life. A corrosion allowance is the amount of material that can be lost to corrosion before the pipe's integrity is compromised. Since Schedule 80 starts with a thicker wall, it inherently has a greater corrosion allowance than Schedule 40, assuming the same minimum required thickness for pressure. This means it will last longer in corrosive service, extending the time between replacements and reducing life-cycle costs.

I've seen this play out with many clients in the chemical and wastewater treatment industries in Southeast Asia. For a given corrosive fluid, a Schedule 40 pipe might have a calculated lifespan of 7 years, while a Schedule 80 pipe could last for 12 years or more. While the initial investment in Schedule 80 is higher, the extended service life and avoidance of one full replacement cycle make it the far more economical choice over the long term. This is a critical calculation that our team at MFY helps clients make, moving the conversation from initial price to total cost of ownership.

However, the impact on flow must also be considered. As discussed, the smaller internal diameter of Schedule 80 increases fluid velocity and frictional losses. This can be a negative performance factor in systems where minimizing pressure drop is key, such as in long-distance water transfer lines or gravity-fed systems. In these cases, if Schedule 40 lacks the required strength, the solution may involve moving to a larger nominal pipe size in Schedule 80 to restore the desired flow area. This highlights the interconnectedness of performance attributes—a choice that enhances structural integrity might negatively impact hydraulic efficiency, requiring a holistic design approach.

Schedule 80 has higher pressure ratingПравда

The thicker wall of Schedule 80 pipe provides superior pressure containment compared to Schedule 40.

Schedule 40 is better for flow efficiencyЛожь

While Schedule 40 has larger internal diameter, "better" depends on application requirements - Schedule 80 may be necessary for pressure/structural needs despite flow impact.

What factors should be considered when choosing between Schedule 40 and Schedule 80?

You're at a crossroads, needing to specify the right pipe schedule. The fear is that a wrong choice will either inflate your budget with over-engineered solutions or expose your project to unacceptable risks. Let MFY help you navigate the critical factors for a confident, correct decision.

Key factors include the system's maximum operating pressure and temperature, the fluid's corrosive properties, external stress and vibration levels, project budget constraints, and governing industry codes and safety standards. A holistic evaluation of these elements is essential for an optimal choice.

Making the right selection is a balancing act between performance requirements and financial realities. It requires a thorough understanding of your application's unique demands. For example, a distributor client of ours in India was supplying a project for a food processing plant. While most of the water lines were low-pressure and suited for Schedule 40, the high-temperature steam-in-place (SIP) cleaning lines4 required the robustness and safety margin of Schedule 80. By not taking a one-size-fits-all approach, they optimized both safety and cost. This is the level of detailed analysis we encourage.

The selection process is an exercise in risk management and value engineering. You must look beyond the initial price per meter and consider the total cost of ownership, which includes installation, maintenance, and the potential cost of failure. The primary driver will always be pressure. You must know the maximum allowable operating pressure (MAOP) of your system, including any potential for surges or water hammer, and select a schedule that can handle it with an appropriate safety factor. But beyond that, consider the environment. Will the pipe be subject to external loads, vibration, or potential for mechanical damage? If so, the superior rigidity and strength of Schedule 80 offer significant advantages. Similarly, for corrosive or erosive media, the greater wall thickness of Schedule 80 provides a longer service life. At MFY, with our fully integrated supply chain, we can provide both schedules rapidly, so your decision can be based on pure engineering merit, not on supplier availability. We empower you to make the best technical choice for your project.

Pressure and Temperature: The Primary Drivers

The single most important factor is the design pressure of the system. You must determine the maximum pressure the pipe will be subjected to during operation, including any potential for spikes or surges. This value must then be compared against the pressure ratings of both Schedule 40 and Schedule 80 pipes for the specific nominal pipe size and material grade you are using. Remember that pressure ratings decrease as temperature increases. The ASME B31 pressure piping codes5 provide detailed tables and formulas to determine a material's allowable stress at various temperatures. A pipe that is perfectly safe at ambient temperature may be inadequate for the same pressure at 200°C.

I always advise my clients, from large engineering contractors to smaller manufacturing companies, to start here. Get the pressure and temperature data right first. A project in the Middle East, a solar thermal plant, required piping to transport heat transfer fluids at high temperatures and pressures. While Schedule 40 might have handled the pressure at lower temperatures, the significant derating of the material's strength at the high operating temperatures made Schedule 80 the only viable and safe option. It is a non-negotiable starting point; if the pressure/temperature combination exceeds the capacity of Schedule 40, the decision is made for you.

You must also consider the system's potential for upset conditions. Water hammer, which is a pressure surge caused by a fluid in motion being forced to stop or change direction suddenly, can create instantaneous pressures many times the normal operating pressure. The superior strength of Schedule 80 provides a much higher safety margin against such events. Neglecting this can lead to catastrophic failures, especially in systems with quick-acting valves.

Application Environment and External Stresses

The second critical factor is the external environment. Piping systems are not just conduits; they are structural elements. You must assess the external loads the pipe will need to endure. Will the pipe be part of a rack that spans long distances? The superior stiffness of Schedule 80 allows for greater spans between supports, which can sometimes reduce the overall installation cost. Will it be exposed to significant vibration from nearby equipment like pumps or engines? The added mass and rigidity of Schedule 80 help to dampen vibration and reduce the risk of fatigue failure at welds and fittings.

A great example comes from an equipment integrator client who builds modular processing skids for export. They standardized on Schedule 80 for all piping on their skids, even for low-pressure lines. Why? Because the skids are subjected to significant stress and vibration during road and sea transport. The robustness of Schedule 80 ensures that the piping system arrives at the end-user's site intact and without any stress-induced damage. It's a decision that prioritizes reliability and product quality over minimal material cost.

Also, consider the potential for mechanical impact. In a busy manufacturing plant, a forklift or other mobile equipment could accidentally strike a pipe. The thicker wall of Schedule 80 offers an invaluable layer of protection against such accidents, preventing a simple mishap from turning into a major leak and costly shutdown. It's a practical consideration of the real-world life of the pipe beyond the design schematics.

Fluid Characteristics and Life Cycle Cost

The nature of the fluid being transported is another key determinant. If the fluid is corrosive or erosive, wall thickness directly translates to service life. A thicker wall provides a larger "corrosion allowance." For instance, in chemical processing or certain mining applications where slurries are transported, the abrasive nature of the fluid will wear away the pipe wall over time. A Schedule 80 pipe will simply last longer than a Schedule 40 pipe under the same conditions.

This is where the conversation shifts from initial purchase price to total cost of ownership (TCO). A Schedule 80 pipe might cost 20-40% more than its Schedule 40 equivalent. However, if it doubles the service life of the piping system, it eliminates the cost of the replacement material, the labor for the second installation, and, most importantly, the production downtime associated with the replacement. I recently walked through this analysis with a client in the pulp and paper industry. Their "black liquor" lines are highly corrosive. By presenting a clear TCO projection, it became evident that specifying Schedule 80 was the most financially sound decision for the long term.

As a supplier, we at MFY see it as our responsibility to facilitate this deeper level of analysis. Our vision is to be a true partner in our clients' success, and that means helping them build efficient, reliable, and cost-effective supply chains. This often means choosing the product with the higher sticker price but the lower life cycle cost, ensuring sustainability and profitability for their operations.

Schedule 80 handles higher pressureПравда

Schedule 80 pipes have thicker walls, making them capable of withstanding higher internal pressures compared to Schedule 40.

Schedule 40 is always cheaperЛожь

While Schedule 40 has a lower initial cost, Schedule 80 may offer better total cost of ownership in corrosive/erosive applications due to longer service life.

What are the typical applications for Schedule 40 and Schedule 80 pipes?

You're trying to match the right pipe schedule to your specific application but are unsure of industry standards. Using the wrong one can lead to non-compliance, safety hazards, or wasteful spending. Let us clarify the common uses so you can choose with confidence.

Schedule 40 is typically used for lower-pressure applications like water distribution, drainage, and general-purpose fluid transfer. Schedule 80 is reserved for high-pressure service, such as steam lines, process piping, hydraulic systems, and applications requiring high structural or corrosion resistance.

Understanding these typical use cases provides a strong starting point for your decision. For example, a construction contractor building a commercial office building would confidently use Schedule 40 stainless steel for the potable water and drainage systems. However, an equipment integrator designing a high-pressure hydraulic power unit would exclusively use Schedule 80 to ensure safety and system integrity. As a key player in China's stainless steel industry, MFY supplies both schedules to a vast range of projects, and this division of application is a consistent theme across all industries we serve.

The selection of a pipe schedule is fundamentally tied to the demands of its intended service environment. It's a decision guided by a combination of physics, engineering codes, and established industry best practices. While Schedule 40 serves as the workhorse for a wide array of utility and low-stress applications, Schedule 80 is the designated choice for systems where pressure, temperature, or external stresses introduce a higher level of risk. Thinking about it in terms of risk management is helpful; the higher the potential consequences of a failure (be it safety-related or financial), the stronger the case becomes for using the more robust Schedule 80. I often tell my distributor clients to profile their customers' needs this way. For a trader selling to general plumbing contractors, Schedule 40 will be the bulk of their business. But for a distributor serving heavy industrial or manufacturing clients, having a ready supply of Schedule 80 is essential to meet their critical application needs. MFY's strong production capacity and inventory in both schedules ensures our partners can confidently serve the full spectrum of their respective markets.

Common Uses for Schedule 40 Pipe

Schedule 40 stainless steel pipe is the go-to choice for a vast range of applications where pressure is relatively low and the external stresses are minimal. Its primary advantage is its cost-effectiveness and lighter weight, which makes it easier to handle and install. You will find Schedule 40 pipe used extensively in residential, commercial, and light industrial settings.

One of the most common applications is in water and fluid distribution. This includes potable water lines in buildings, low-pressure water mains, and general fluid transfer lines in manufacturing plants where the product is not under significant pressure. For instance, many food and beverage processing facilities use Schedule 40 304L or 316L stainless steel pipe for transporting ingredients, washdown water, or finished products. A client of ours, a large beverage manufacturer in Southeast Asia, uses thousands of meters of MFY's Schedule 40 pipe for exactly these purposes. It provides the necessary hygiene and corrosion resistance without the unnecessary cost and weight of a heavier schedule.

Other typical applications include drainage systems, vent pipes, and low-pressure compressed air lines. It is also frequently used for structural purposes where high strength is not the primary requirement, such as for handrails, architectural elements, and support frames for light equipment. Its combination of moderate strength, good corrosion resistance (depending on the alloy), and lower cost makes it an incredibly versatile product for non-critical systems.

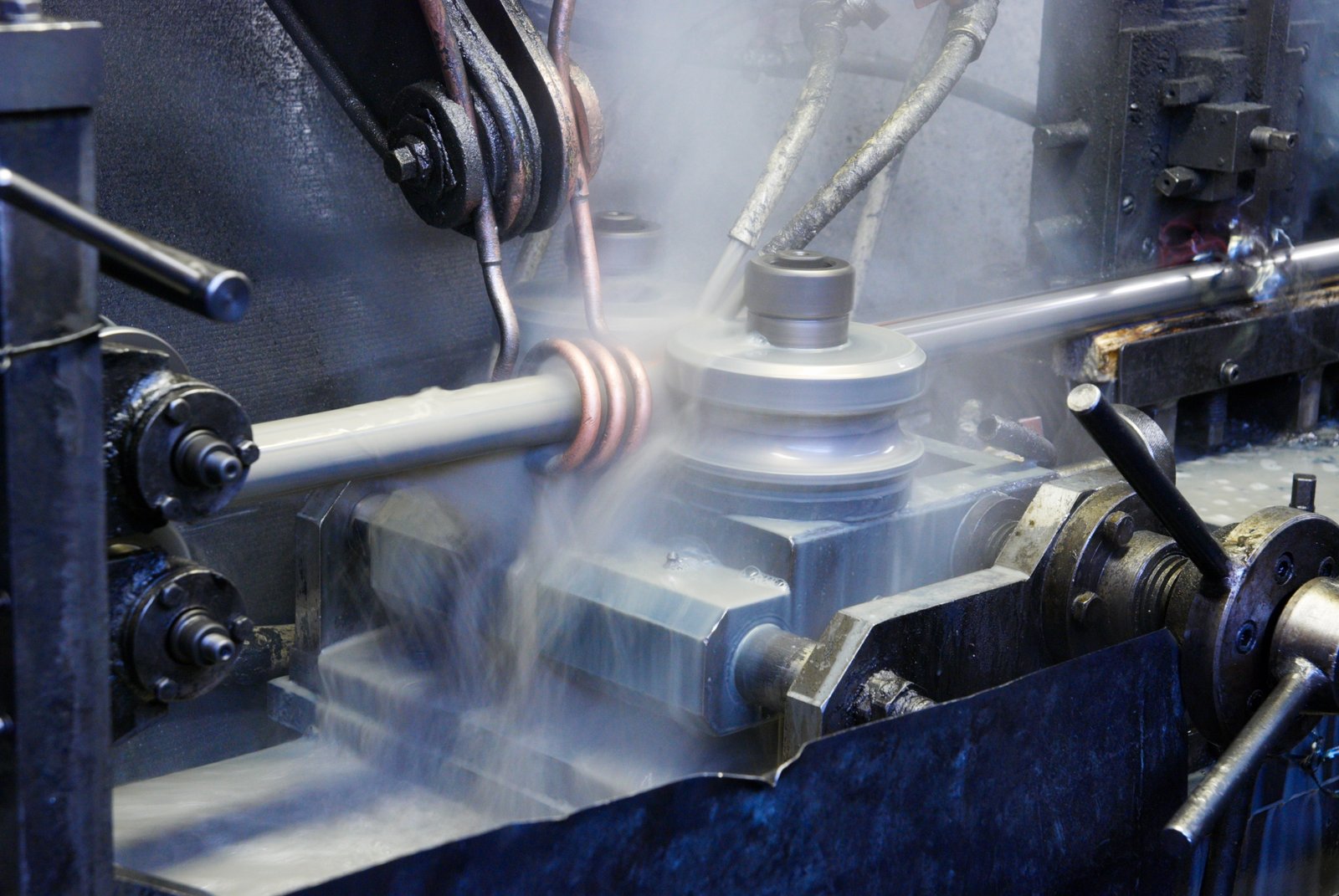

High-Stakes Applications for Schedule 80 Pipe

Schedule 80 stainless steel pipe is specified when the stakes are higher. Its domain is high-pressure and high-temperature environments where system integrity is paramount. Any application where a failure could result in significant safety hazards, environmental damage, or extreme financial loss will typically mandate the use of Schedule 80 or even heavier schedules (like Schedule 160 or XXS).

The most prominent applications are in the process industries. Chemical plants, oil refineries, and power generation facilities use Schedule 80 for transporting high-pressure steam, process chemicals, hydraulic fluids, and other hazardous materials. For example, ASME B31.1 (Power Piping) code often requires Schedule 80 for steam lines operating at high pressures and temperatures to ensure safety and reliability. We regularly supply Schedule 80 pipe to engineering contractors building power plants and petrochemical facilities across Russia and the Middle East, where it is the undisputed standard for critical service lines.

Beyond pressure, Schedule 80 is also chosen for its structural superiority. It's used in applications with high external loads or severe vibration. This includes piping on offshore platforms that must withstand harsh environmental forces, or in industrial plants where it's run adjacent to heavy vibrating machinery. Furthermore, its greater wall thickness makes it ideal for applications involving corrosive or erosive fluids, such as in mining slurry transport or certain chemical processing lines, where the extra material provides a longer service life.

Industry-Specific Choices and Nuances

The choice between Schedule 40 and Schedule 80 can also be guided by industry-specific norms and regulations. Certain industries have developed their own best practices based on decades of operational experience. Understanding these nuances is key for any supplier or contractor working in those fields.

In the pharmaceutical and bioprocessing industries, for example, while pressures are often low, the need for high-purity systems can sometimes influence pipe choice, though Schedule 10 or Schedule 40 is more common for hygienic reasons (smoother internal welds). However, utility lines within the same facility, such as those for plant steam or compressed air, will follow standard industrial practice, often requiring Schedule 80 for high-pressure headers.

In commercial construction, Schedule 40 is the default for plumbing and HVAC systems. However, in the fire protection systems within that same building, the sprinkler mains might be specified as Schedule 40, but certain parts of the system connected directly to high-pressure pumps could require Schedule 80. It's a story of choosing the right tool for the specific job, even within the same project. As a diversified supplier, MFY has the agility to provide these mixed-schedule orders efficiently, ensuring that our clients, whether they are large-scale contractors or specialized distributors, have access to the precise products their projects demand.

Schedule 40 is for low-pressure applicationsПравда

Schedule 40 pipes are commonly used in water distribution and drainage systems where pressure requirements are relatively low.

Schedule 80 is lighter than Schedule 40Ложь

Schedule 80 pipes have thicker walls and are heavier than Schedule 40 pipes, designed specifically for high-pressure applications.

What guidelines can help in making an informed decision on pipe schedule selection?

You need a clear, reliable method for choosing between pipe schedules to avoid costly errors or safety oversights. Navigating datasheets and codes can be confusing, leading to uncertainty. Let's provide a straightforward framework to ensure you make the right choice, every time.

First, determine the required wall thickness based on your system's design pressure and temperature using established engineering formulas (e.g., ASME B31.3). Then, evaluate factors like corrosion allowance and external loads. Ly, compare the compliant schedules on a total cost of ownership basis.

This structured approach removes guesswork, grounding your decision in solid engineering principles and financial prudence. It’s a process we walk through daily with our clients at MFY. For example, a manufacturing client might find that while Schedule 40 meets their pressure needs, adding a corrosion allowance for their specific chemical process makes Schedule 80 the more durable and cost-effective long-term solution. Our goal is to empower you with this decision-making clarity.

Making an informed decision on pipe schedule is about following a logical and hierarchical process of elimination and verification. It's less about a gut feeling and more about a systematic analysis of requirements against specifications. You begin with the non-negotiable elements—pressure and temperature—which will immediately narrow your options. From there, you layer on secondary but still critical considerations like environmental stress and the need for a corrosion buffer. Ly, you can look at the economic impact, not just of the pipe itself but of the entire installed system. I've found that when clients follow this path, the correct choice often becomes self-evident. It prevents the common pitfall of letting the initial purchase price disproportionately influence a decision that has long-term safety and operational consequences. As your partner, MFY provides not just the high-quality stainless steel pipe but also the technical support to help you confidently navigate this critical selection process, ensuring your project is built on a foundation of safety and reliability.

Guideline 1: The Pressure-First Principle

Your analysis must begin with pressure and temperature. This is the foundational, non-negotiable step. First, identify the maximum operating pressure (MOP) of your system. Crucially, you must also account for any potential surge pressures (water hammer) or upset conditions that could cause pressure spikes. Second, determine the maximum operating temperature, as the allowable stress of stainless steel decreases at elevated temperatures. With these two data points—design pressure and design temperature—you can use the formulas provided in the relevant piping code (e.g., ASME B31.1 for power piping or B31.3 for process piping) to calculate the minimum required wall thickness.

This calculation will give you a specific thickness value in inches or millimeters. You then compare this required thickness to the actual nominal wall thickness of standard pipe schedules. For example, if your calculation for a 4-inch pipe requires a minimum wall thickness of 0.250 inches, you would look at a pipe schedule chart. You'd find that 4-inch Schedule 40 pipe has a nominal wall of 0.237 inches, which is insufficient. The next step up, Schedule 80, has a wall of 0.337 inches, which safely exceeds the requirement. In this case, the decision is clear and dictated by engineering calculations: Schedule 80 is required.

I always emphasize to our clients, particularly engineering and construction contractors, to perform and document this calculation for every system. It is the most fundamental step in ensuring the safety and compliance of their design. This data-driven approach removes all ambiguity from the initial selection.

Guideline 2: Assess Environmental and Service Factors

Once you have a schedule that meets the pressure-temperature requirements, you must then consider secondary factors. If both Schedule 40 and Schedule 80 are technically compliant from a pressure standpoint (as is often the case in lower-pressure systems), these factors will drive your decision. The first to consider is the need for a corrosion/erosion allowance. If the fluid being transported is corrosive or abrasive, how much material loss do you anticipate over the pipe's desired lifespan? Adding this allowance to your minimum calculated wall thickness may push you into the next heavier schedule.

A client in the mining industry provides a perfect case study. They were transporting a moderately pressurized slurry. While Schedule 40 could handle the pressure, the erosive nature of the slurry was expected to cause 0.050 inches of wall loss over five years. By adding this erosion allowance to the pressure-based minimum wall thickness, their calculations showed that only a Schedule 80 pipe would provide the required structural integrity at the end of that five-year service life. Choosing Schedule 80 was a proactive decision to ensure long-term reliability.

You must also evaluate external stresses. Will the pipe be subject to significant vibration, potential mechanical impact, or long, unsupported spans? If any of these are true, the superior stiffness and durability of Schedule 80 may be warranted even if it is not strictly required for pressure containment. This is an investment in the overall robustness and resilience of your system.

Guideline 3: Conduct a Total Cost of Ownership (TCO) Analysis

The final step is to analyze the economics, but through the lens of Total Cost of Ownership (TCO), not just the initial purchase price. If your analysis from the first two guidelines indicates that both schedules are technically viable, a TCO analysis will help you determine the most financially sound option. This analysis should include the initial material cost, shipping and handling costs (heavier pipes cost more to transport), and installation costs (thicker pipes require more time and consumables to weld).

However, it must also factor in the long-term operational and maintenance costs. If Schedule 80's greater wall thickness provides a longer service life in your specific application, how does that impact life-cycle cost? Calculate the cost of future replacements, including materials, labor, and the critically important cost of lost production during downtime. Often, an initially more expensive Schedule 80 pipe can prove to be the cheaper option over a 10 or 20-year period.

At MFY, our vision is to help global clients build efficient supply chains. Efficiency isn't just about low initial cost; it's about long-term value and reliability. We encourage our partners, from distributors to end-users, to adopt this TCO mindset. By providing transparent data on our products and drawing on our broad industry experience, we help you make decisions that are not only safe and compliant but also economically optimal for the entire life of your project.

Pressure determines minimum pipe wall thicknessПравда

ASME B31.3 formulas use design pressure/temperature to calculate required wall thickness, forming the basis for schedule selection.

Schedule 40 always has lower total costЛожь

Total Cost of Ownership analysis may show Schedule 80 is cheaper long-term due to extended service life and reduced downtime.

Заключение

Choosing between Schedule 40 and Schedule 80 boils down to a rigorous assessment of pressure, temperature, environmental stress, and fluid properties. While Schedule 40 is a cost-effective choice for low-pressure applications, Schedule 80 provides essential safety and durability for high-stakes, demanding environments.

-

Discover the formula used to determine maximum pressure capacity in pipes ↩

-

Discover considerations for pipe selection in high-vibration oil and gas environments. ↩

-

Explore strategies for balancing pipe strength and hydraulic efficiency in heating projects. ↩

-

Explore the reasons Schedule 80 is preferable for high-temperature cleaning lines in industrial applications ↩

-

Understand the role of ASME codes in determining pipe stress and ensuring compliance with standards ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.