Инкотермс 2020 пояснения для заказов труб навалом: FOB vs CIF vs DDP

Are you struggling to decide on the right Incoterm for your bulk stainless steel pipe orders? Choosing incorrectly can trigger unforeseen costs, frustrating delivery delays, and customs issues, ultimately threatening your project's budget and timeline. Understanding the critical differences between FOB, CIF, and DDP is your first step toward mastering your supply chain.

Incoterms 2020 are a set of globally recognized trade rules defining the specific responsibilities of sellers and buyers. For bulk pipe orders, the key terms—FOB, CIF, and DDP—determine who manages and pays for shipping, insurance, and customs, directly impacting your project’s total cost and risk.

Choosing the right Incoterm is far more than a logistical checkbox; it's a strategic decision that profoundly impacts your supply chain's efficiency and your company's bottom line. In my role at MFY, I’ve guided countless clients through this decision-making process. I want to share some of the practical insights I've gained to demystify these terms and empower you to select the optimal one for your next major pipe procurement.

The landscape of international trade can appear to be a daunting maze of complex regulations and jargon. At its heart, however, it’s simply about the clear allocation of risk and responsibility. The International Chamber of Commerce1 designed Incoterms to create a universal language for these transactions. When dealing with high-value, large-volume goods like stainless steel pipes, the stakes are considerably high. The conversation is not just about who pays for the freight. It is about who bears the risk if a shipment of specialized tubing is damaged at sea, who is responsible for costly delays at customs, and who ultimately has control over the entire logistics chain. Critically, your choice of Incoterm reflects your organization's risk appetite, cash flow strategy, and internal operational capabilities. A large, established engineering contractor with a sophisticated logistics department might prefer FOB to maintain control and manage costs, whereas a smaller distributor might opt for the simplicity of DDP, willingly paying a premium for a hands-off experience. This decision is a cornerstone of your procurement strategy.

What are the basic principles of Incoterms 2020 relevant to bulk pipe orders?

Are you feeling overwhelmed by the dense terminology surrounding Incoterms? Misinterpreting these fundamental rules can lead to expensive disputes and shipment delays, a particularly damaging scenario when dealing with high-value cargo like stainless steel pipes. Let’s break down the core principles that truly matter for your business.

The core principles of Incoterms 2020 for bulk pipe orders focus on clearly defining three key things: the point where risk transfers from seller to buyer, the precise allocation of all logistical costs, and the division of responsibilities for tasks like transport and customs clearance.

These principles are the foundational pillars of any international trade contract. It's best to view them not as rigid, unchangeable rules, but as a flexible framework that you can leverage to construct a procurement process perfectly tailored to your project's specific requirements. When a client, for instance, a major equipment manufacturer in India, approaches us for a multi-ton order of stainless steel tubing, our first discussion after settling on product specifications is almost always about Incoterms. They need to know with absolute certainty the exact moment our responsibility for those goods ends and theirs begins. This isn't merely about paperwork or legal formalities; it's about the practical protection of a significant financial asset. My experience has shown that establishing this clarity from the very beginning prevents the vast majority of potential downstream problems, from unexpected port charges to frustrating customs holds. This initial understanding empowers our clients to plan their project financing, on-site logistics, and installation timelines with a much higher degree of accuracy and confidence. A firm grasp of these core ideas will elevate your approach from simply buying pipes to strategically sourcing them for a competitive advantage.

To truly leverage Incoterms, we must move beyond surface-level definitions and delve into the practical mechanics of how these principles operate in the context of sourcing industrial materials like stainless steel pipes. The entire framework is built to answer three critical questions: When does my risk begin? What am I actually paying for? And what tasks am I responsible for? Answering these questions with clarity is the first step toward building a resilient and cost-effective supply chain. It’s a conversation I have daily with partners, whether they're seasoned procurement managers or business owners new to international trade.

Defining the Point of Delivery and Risk Transfer

The concept of "delivery" in Incoterms is perhaps the most frequently misunderstood principle. In everyday language, delivery means the goods have arrived at your doorstep. In the world of Incoterms, however, "delivery" signifies the precise point at which the risk of loss or damage to the goods transfers from the seller to the buyer. For a shipment of stainless steel pipes, this could be the moment they are safely loaded on board the vessel at the port of origin (as in an FOB contract) or at another agreed-upon point. This distinction is not trivial; it's the dividing line of liability.

Let me share a real-world example. We recently worked with a client, let's call them "BuildRight Construction," on a major infrastructure project in Vietnam. They placed a substantial order for stainless steel structural tubes and chose the term FOB Shanghai. This meant our responsibility at MFY extended to producing the pipes, transporting them to the Port of Shanghai, clearing them for export, and ensuring they were loaded safely onto the ship nominated by BuildRight. The moment those tubes were on board the vessel, the risk transferred to them. If a typhoon in the South China Sea were to cause damage to the cargo mid-transit, it would be BuildRight's responsibility to file a claim with their insurance provider, not ours. This clarity was essential for their project's risk management protocol and allowed them to secure appropriate insurance coverage tailored to their specific needs.

This clear demarcation is a powerful tool for dispute avoidance. Industry data from various trade bodies often highlights that conflicts over goods damaged in transit are a significant source of commercial disputes, sometimes accounting for nearly a third of all incidents. A clearly defined risk transfer point, as stipulated by your chosen Incoterm, is your primary defense. It transforms a potentially ambiguous situation into a clear, contractually-defined allocation of responsibility, acting as a crucial financial and operational shield for both buyer and seller.

Allocation of Costs: Who Pays for What?

Once risk is understood, the next pillar is the transparent allocation of costs. A bulk pipe order involves a long chain of cost-generating activities: inland transport from our MFY facility to the port, terminal handling charges (THC) at the port of loading, ocean freight, marine insurance, unloading charges at the destination port, import duties and taxes, and final inland transport to your facility. Incoterms provide a precise blueprint that dictates which party is responsible for each of these costs. This prevents the dreaded "surprise charge" that can wreck a project budget.

For example, when we structure a deal on a CIF (Cost, Insurance, and Freight) basis for a client in Dubai, our quoted price provides them with a clear picture. They know that this single figure covers the cost of the stainless steel pipes themselves, the cost of a marine insurance policy, and all freight charges to get the shipment to Jebel Ali port. This allows for straightforward budgeting. In contrast, an FOB price will naturally be lower, but this initial saving is only part of the story. The client must then independently budget for their own ocean freight and insurance costs, which can be highly volatile depending on global shipping demand and fuel prices.

To illustrate this, consider a hypothetical 100-ton order of stainless steel pipes from Shanghai, China, to Nhava Sheva, India. The cost responsibilities would be divided as follows:

| Cost Component | FOB Shanghai (Buyer Responsibility) | CIF Nhava Sheva (Buyer Responsibility) | DDP Buyer's Warehouse (Buyer Responsibility) |

|---|---|---|---|

| Production of Pipes | Seller (MFY) | Seller (MFY) | Seller (MFY) |

| Export Customs & Port Fees (Origin) | Seller (MFY) | Seller (MFY) | Seller (MFY) |

| Ocean Freight | Buyer | Seller (MFY) | Seller (MFY) |

| Marine Insurance | Buyer | Seller (MFY) | Seller (MFY) |

| Port Fees & Unloading (Destination) | Buyer | Buyer | Seller (MFY) |

| Import Customs, Duties & Taxes | Buyer | Buyer | Seller (MFY) |

| Delivery to Warehouse | Buyer | Buyer | Seller (MFY) |

This table clearly shows how the buyer's financial responsibility expands or contracts based on the chosen term.

Division of Responsibilities: From Export to Import Clearance

The final core principle revolves around the division of operational responsibilities. Beyond just cost and risk, who is actually in charge of executing the key logistical tasks? This includes arranging the main carriage (booking the vessel), contracting for an insurance policy, and, critically, managing the customs formalities at both the port of export and the port of import. Your choice of Incoterm dictates this division of labor.

This is where a supplier's capabilities can create significant value. Consider a client of ours in Russia, an engineering firm specializing in equipment integration. They are experts in their technical field but have limited experience navigating Chinese export procedures or booking international sea freight. For them, a CIF or even a DDP term is immensely valuable. By choosing CIF, they task us with managing all the complexities of export clearance and freight forwarding. If they were to choose DDP, we would also manage the intricate Russian import customs process. This "service" aspect of the Incoterm simplifies their procurement process, allowing them to focus on their core business. It’s a key part of the one-stop solution we strive to provide at MFY.

From a critical standpoint, this division of responsibilities creates a fundamental trade-off between convenience and control. A buyer who opts for an FOB contract takes on more responsibility, but in return, they gain significant control. They can select their own freight forwarder, choose the shipping line, and manage the transit schedule to align perfectly with their production or inventory needs. This level of control can be a powerful tool for cost optimization, especially for high-volume shippers. Conversely, a DDP contract offers maximum convenience but requires the buyer to relinquish nearly all control over the logistics process. This strategic balance between convenience and control is a central consideration when selecting the right Incoterm for your bulk pipe order.

Incoterms define risk transfer pointsПравда

Incoterms 2020 clearly specify the exact moment when responsibility for goods transfers from seller to buyer, which is crucial for bulk pipe orders.

DDP gives buyers logistics controlЛожь

DDP actually means the seller maintains full control of logistics, while buyers choosing FOB retain more control over shipping arrangements.

How do FOB, CIF, and DDP apply to bulk pipe orders in the current global trade environment?

Are you feeling uncertain about which specific Incoterm—FOB, CIF, or DDP—is the right fit for your large-scale pipe shipment? In today's volatile global market, a suboptimal choice can quickly expose your business to wildly fluctuating freight rates and unexpected port charges, disrupting your entire project.

For bulk pipe orders, FOB (Free On Board) empowers buyers with control over shipping logistics. CIF (Cost, Insurance, and Freight) offers convenience by having the seller arrange sea transport and insurance. DDP (Delivered Duty Paid) provides a complete, hassle-free, door-to-door service where the seller manages all logistics and customs.

The decision between these three popular terms often serves as a mirror, reflecting a company’s operational maturity, risk management strategy, and overall procurement philosophy, especially in the post-pandemic era of unpredictable shipping schedules and soaring costs. For example, I’ve observed many of our experienced clients in the Middle East, who possess strong, long-standing relationships with major freight forwarders, gravitating back towards FOB terms. This allows them to actively negotiate their own freight rates and navigate the volatile market more effectively. Conversely, clients engaged in critical infrastructure projects with inflexible deadlines, like a recent power plant we supplied in Southeast Asia, overwhelmingly prefer the predictability of CIF or DDP. For them, the premium paid for the assurance that all logistics are managed by a single, accountable partner like MFY is a worthwhile investment in project security. This isn't just a theoretical discussion; it's a dynamic, daily reality in our business that shapes how we structure partnerships to meet diverse client needs and successfully navigate the ever-shifting complexities of today's global trade environment.

In the dynamic theater of global trade, Incoterms are not static rules but adaptive tools. The "best" choice is fluid, heavily influenced by prevailing market conditions, geopolitical factors, and your company's specific circumstances. The theoretical definitions of FOB, CIF, and DDP come to life when applied to real-world scenarios involving large-volume shipments of industrial goods like stainless steel pipes. Let's dissect the practical application and strategic implications of each of these terms in the context of the challenges and opportunities that define today's market. Each term offers a distinct balance of control, cost, and convenience that can either enhance or hinder your supply chain's performance.

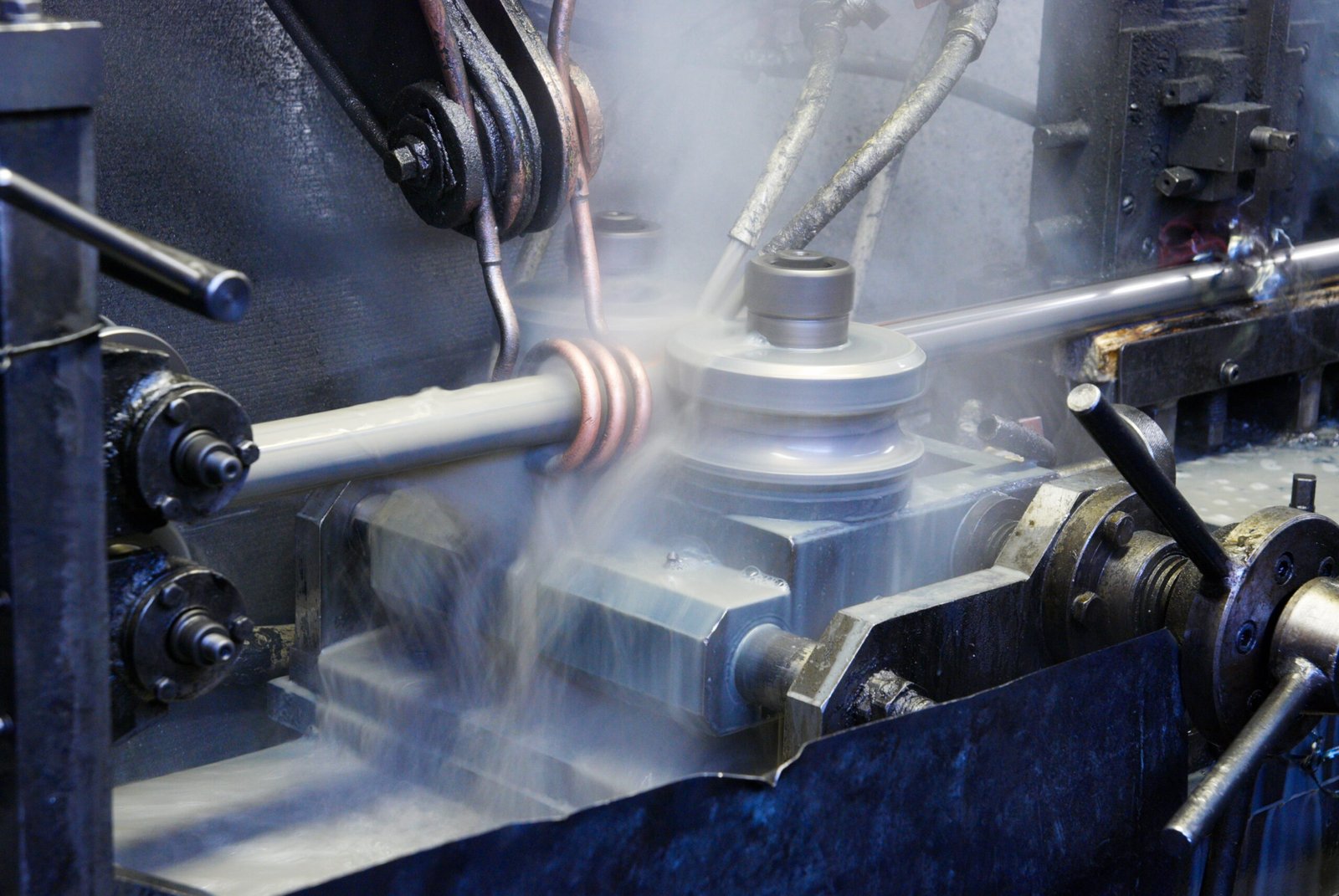

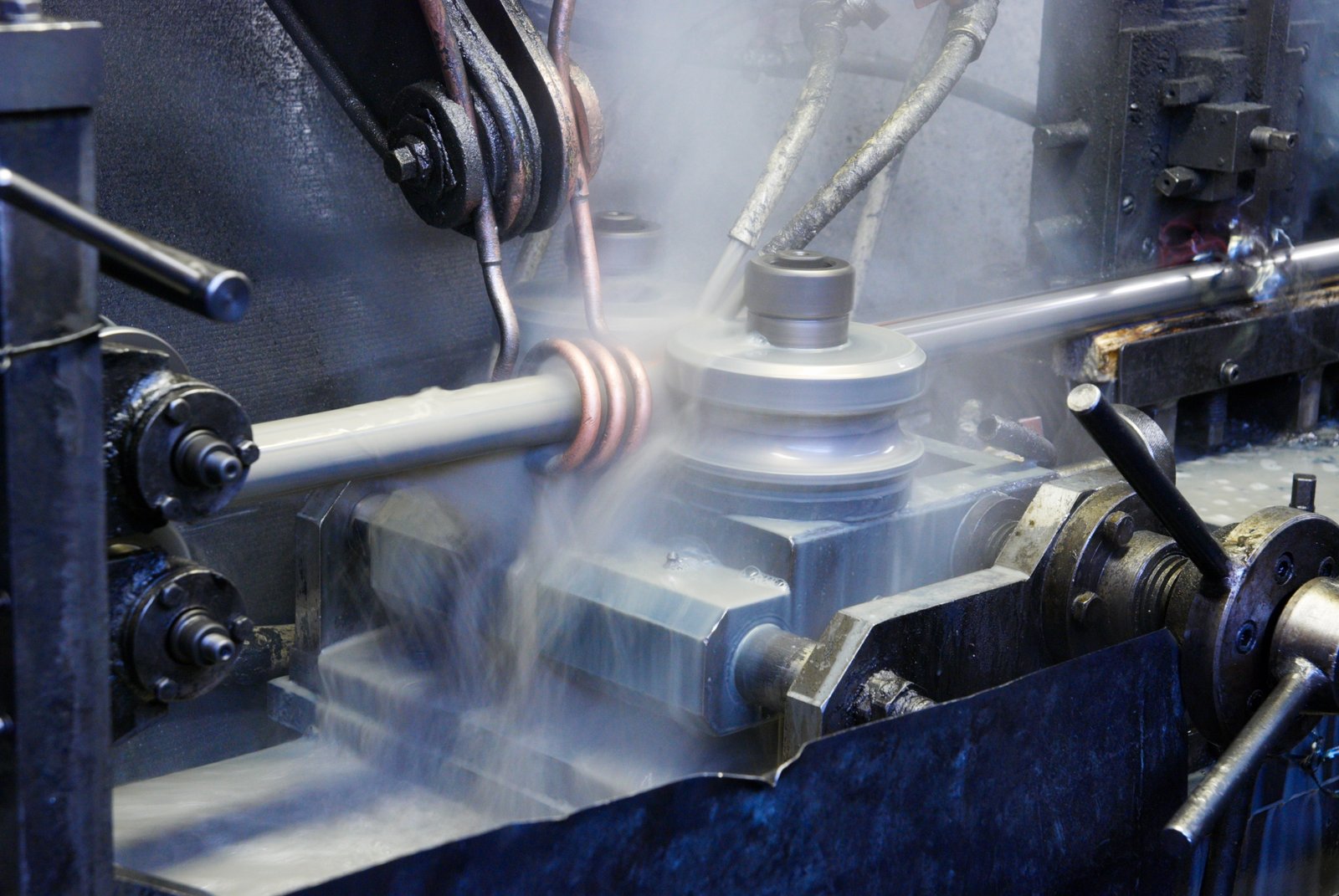

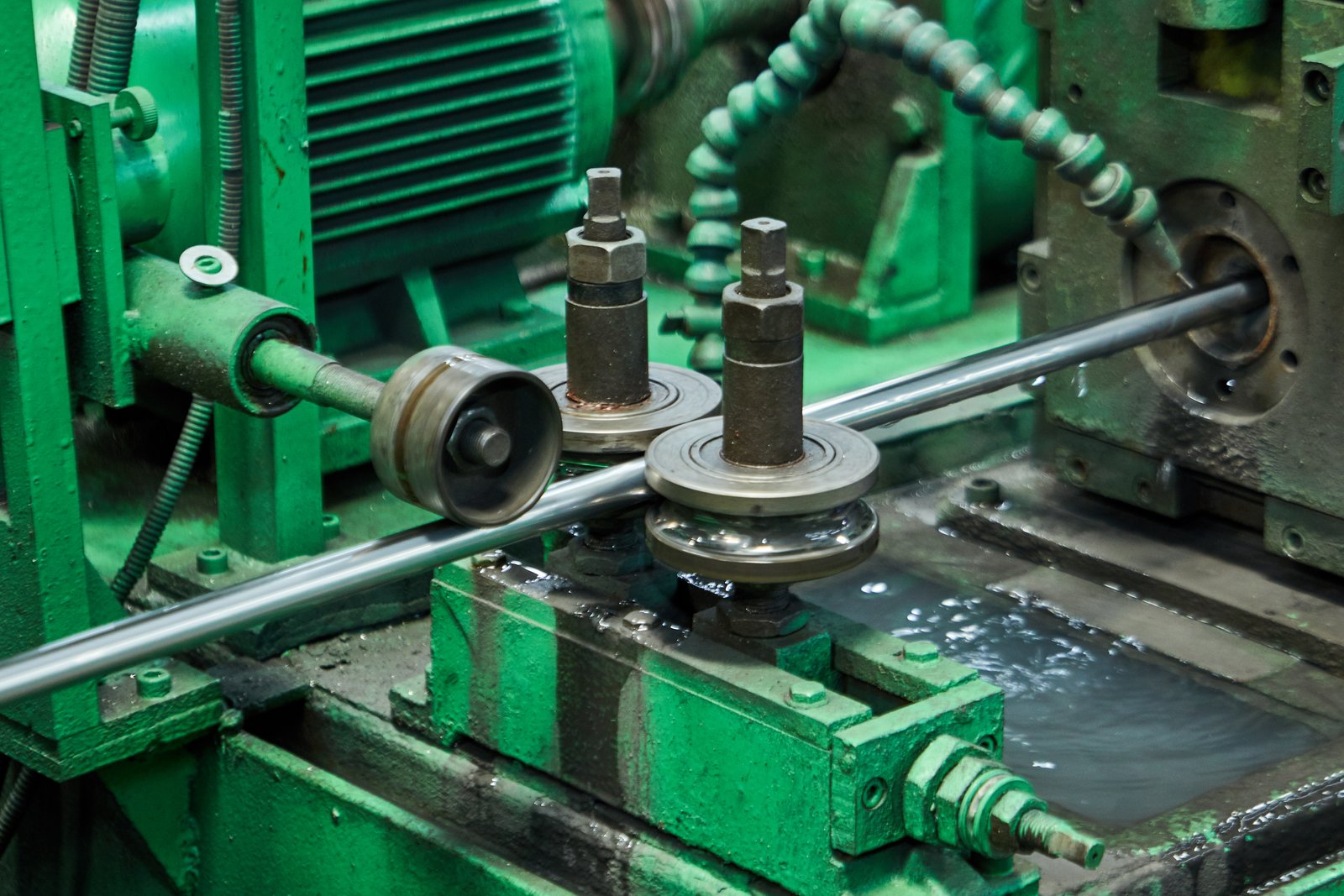

FOB (Free On Board): The Strategy for Maximizing Buyer Control

FOB is arguably the most common Incoterm for bulk commodities, and for good reason. Under an FOB agreement (e.g., FOB Shanghai), our responsibility as the seller, MFY, is to manufacture the pipes to specification, handle all export documentation and customs clearance in China, and ensure the goods are loaded safely onto the vessel nominated by you, the buyer, at the designated port. The very moment the last pipe is securely on board, the risk and all subsequent costs transfer to you. This is a clean, decisive handover point.

The primary advantage of FOB is control. I recently worked with an established distributor in India who handles an annual volume of over 5,000 tons of stainless steel pipes from various suppliers. They exclusively use FOB terms. Why? Because it allows their logistics team to consolidate our shipment with others, negotiate high-volume contract rates with their preferred shipping lines, and maintain full authority over the vessel's schedule. This level of control is a powerful strategic asset. It is critical for their just-in-time inventory management system and allows them to significantly reduce per-unit shipping costs—a saving they could never realize under a CIF agreement where we would select the carrier.

In today's market, this control is more valuable than ever. We've all seen the extreme volatility in shipping costs. According to market analysts like Drewry, global freight rates can fluctuate by well over 100% within a single year. By choosing FOB, our Indian partner insulates their business from our freight cost estimations. They can instruct their forwarder to time vessel bookings to capitalize on market dips or secure space during peak seasons, giving them a level of agility and cost management that is impossible when the seller controls the freight. It is a strategy for the hands-on, experienced buyer.

CIF (Cost, Insurance, and Freight): The Classic Choice for Budgetary Convenience

CIF has long been a popular choice for buyers who prioritize convenience and predictable upfront costs. When we agree to a CIF contract (e.g., CIF Jebel Ali), our quoted price is more inclusive. We at MFY are responsible for arranging and paying for all costs to transport the stainless steel pipes to the destination port, including the ocean freight and a basic level of marine insurance. For the buyer, this simplifies budgeting immensely—they have one single, clear cost to manage for the goods and their transportation to their country's port.

A perfect example is a construction contractor we supplied in Vietnam for a new high-rise project. As a construction firm, their core expertise is in building, not international logistics. They chose CIF Haiphong because they wanted a single, landed cost from us that covered the pipes and their entire journey across the sea. This allowed them to lock in a key component of their project budget early on, without needing to dedicate internal resources to negotiating with shipping lines. However, a crucial part of my consultation with them was to highlight the nuances of CIF. The risk, unlike the cost, still transfers from us to them the moment the pipes are loaded on the vessel back in Shanghai.

This leads to a critical point about CIF that requires careful consideration: the insurance. While the seller (MFY) arranges and pays for the insurance, the buyer is the beneficiary. If the cargo is damaged, it is the buyer who must navigate the claims process. Standard CIF terms only require a minimum level of coverage (Institute Cargo Clauses 'C'), which may not be sufficient for high-value or specialized pipe orders. We always advise our CIF clients to review the policy details and consider requesting broader 'A' clause coverage for all-risk protection. The convenience of CIF is undeniable, but it should not lead to complacency regarding risk management.

DDP (Delivered Duty Paid): The Ultimate Turnkey Solution for Simplicity

DDP represents the highest level of service from the seller and the greatest ease for the buyer. Under DDP terms, we as the seller assume all responsibilities, risks, and costs until the goods are delivered to the buyer's final named destination, cleared for import, with all duties and taxes paid. For example, a DDP Moscow warehouse agreement would mean MFY manages the entire journey from our factory door to our client's facility door in Russia, including the complex import customs process.

We recently handled a DDP order for an engineering contractor in Russia who required highly specialized pipes for a critical equipment upgrade. The Russian customs system is notoriously complex and requires significant expertise to navigate efficiently. The client chose DDP precisely to eliminate this entire challenge from their project scope. They wanted zero engagement with shipping lines or customs authorities. Our role, executed through our network of experienced logistics partners, was to provide a true, seamless, door-to-door service. This "white glove" approach ensured the pipes arrived at their project site on schedule without any logistical burden on their team.

However, this ultimate convenience comes at a price and with its own set of strategic considerations. The DDP price will be the highest of the three options, as it incorporates all logistical costs and a risk premium for the seller. More importantly, it requires an immense level of trust and capability on the part of the seller. For us at MFY to offer DDP, we must have absolute confidence in our ability to manage the import regulations of the destination country. A seller who miscalculates duties or encounters unforeseen customs hurdles can cause catastrophic delays for the buyer. Therefore, while DDP is an excellent option for buyers seeking to minimize risk and administrative workload, it should only be undertaken with a supplier who has proven expertise in that specific trade lane.

FOB transfers risk at loadingПравда

Under FOB terms, risk transfers from seller to buyer the moment goods are loaded onto the vessel at origin port.

CIF includes full insuranceЛожь

CIF only requires minimum 'C Clause' insurance coverage, not comprehensive protection for specialized cargo.

What challenges do businesses face when choosing between FOB, CIF, and DDP for bulk pipe shipments?

Does the decision between FOB, CIF, and DDP feel like a high-stakes gamble? Businesses often face significant challenges in this choice, from hidden costs in CIF contracts to the logistical complexities of FOB, making the wrong decision a potentially costly misstep for your project.

Businesses face key challenges when choosing Incoterms for pipe shipments, including managing volatile freight costs under FOB, assessing the adequacy of seller-provided insurance in CIF, and facing the high costs and loss of control associated with DDP, all while navigating complex customs regulations.

Navigating these challenges is a core part of my daily conversations with clients. The ideal Incoterm is rarely a static choice; it often shifts based on the specific project, the destination country, and the current market climate. A recent case comes to mind involving a manufacturing client in Southeast Asia. They had always favored CIF for its simplicity. However, as freight rates became increasingly erratic, the "all-in" CIF price we quoted began to include a significant risk premium for this volatility, making it less competitive. This opened up a strategic discussion about them potentially taking control of the freight via an FOB arrangement. We walked them through the process, connected them with trusted freight forwarders, and helped them analyze the cost-benefit trade-off. It’s a perfect example of how the challenges presented by the market create opportunities for businesses to evolve their procurement strategies. It’s not just about selecting a term from a list; it’s about building a responsive and resilient supply chain prepared for today’s realities.

The selection of an Incoterm for a bulk pipe shipment is a strategic decision laden with potential pitfalls. While the rulebook provides clear definitions, the real-world application is muddied by market volatility, information asymmetry, and the varying capabilities of buyers and sellers. The challenges are not merely theoretical; they have tangible impacts on project timelines, profitability, and client relationships. Understanding these hurdles is the first step toward overcoming them. As a supplier, our goal at MFY is not just to sell pipes but to help our clients structure a deal that is secure, transparent, and mutually beneficial, which means confronting these challenges head-on.

The Challenge of Cost Volatility and Control in FOB

The primary appeal of FOB is control, but this control comes with the significant responsibility of managing costs in a fluctuating market. For a buyer of stainless steel pipes, the single largest variable cost they assume under FOB is the ocean freight. This is a market that has seen unprecedented volatility in recent years. A procurement manager might budget for freight based on a quote received on Monday, only to find the actual booking cost has jumped 15% by Friday. This can wreak havoc on project budgets, especially for construction and engineering firms working with fixed-price contracts.

A client of ours, a medium-sized distributor in the UAE, recently experimented with moving from CIF to FOB to try and lower costs. They quickly discovered the challenge. Their annual volume wasn't quite large enough to command the top-tier rates from shipping lines that major importers receive. They also found that securing container space during peak shipping seasons out of China was a major struggle without the established relationships that we, as a high-volume shipper, maintain. They faced a steep learning curve in freight booking, rate negotiation, and managing carrier relationships.

This illustrates the core FOB challenge: the buyer must possess, or have access to, genuine logistics expertise. Without it, the "control" offered by FOB can become a liability. The potential cost savings are attractive, but they must be weighed against the internal resources required to manage the freight process effectively and the financial risk posed by rate volatility. A business must honestly assess its operational capacity before taking on this responsibility.

Information Asymmetry and Risk in CIF Contracts

CIF is often positioned as the convenient, "easy" option, but this convenience can mask hidden risks stemming from information asymmetry. Under CIF, the seller arranges both the freight and the insurance, but the buyer bears the transit risk. The challenge for the buyer is a lack of transparency and control over the quality of these services. The seller, motivated to keep their CIF price competitive, might choose the cheapest shipping line, which could have a reputation for delays and poor service. More critically, they may arrange for only the minimum required insurance coverage.

I recall an incident with a new client purchasing a large quantity of polished stainless steel pipes for an architectural project. They agreed to a CIF term with a previous supplier. When the shipment arrived, a portion of the pipes had suffered significant water damage due to a leaky container. It was only then that they discovered the insurance policy was a bare-bones policy (ICC 'C') that did not cover this type of damage. They were left with unusable material and a significant financial loss. This is the classic CIF trap.

When we at MFY handle a CIF shipment, we make it our policy to provide our clients with the full details of the shipping line and a copy of the insurance certificate2 upfront. We see it as our duty to help them understand what they are covered for. The challenge for any business using CIF is to be proactive. They must demand this transparency from their supplier. They need to ask the critical questions: Which carrier are you using? What is their on-time performance record? Can I see the insurance policy, and does it adequately cover the full value of my cargo against all relevant risks?

The High Cost and Dependency of DDP

DDP, the "door-to-door" service, presents the challenge of high cost and total dependency on the seller. The price of a DDP contract is inevitably the highest, as the seller is factoring in every conceivable cost and risk, from freight and insurance to import duties, VAT/GST, and potential customs inspection fees. The buyer pays a significant premium for the convenience of this turnkey solution. While this eliminates uncertainty in the buyer's budget, it also means they may be paying more than necessary if the seller overestimates these costs.

The more significant challenge, however, is the complete loss of control and the dependency it creates. If the seller's logistics agent makes a mistake on the customs declaration in the destination country, it is the buyer's cargo that gets held up. A project can be delayed for weeks due to an issue that the buyer has no visibility or control over. This is a particularly acute risk in countries with complex and bureaucratic import procedures.

We only offer DDP to markets where we have long-standing, proven logistics partners whom we trust implicitly. For a buyer considering DDP, the challenge is one of due diligence. You are not just buying a product; you are buying a logistics service. You must vet your supplier's experience3 and track record in your specific country. Ask for references from other DDP clients in your region. The convenience of DDP is immense, but it requires placing immense trust in your supplier's capabilities. A failure on their part can have direct and severe consequences on your operations.

FOB shifts freight cost risk to buyerПравда

Under FOB terms, the buyer assumes responsibility for freight costs and their volatility after goods pass the ship's rail.

CIF always provides adequate insuranceЛожь

CIF only requires minimum ICC 'C' coverage by default, which often excludes common risks like water damage during transit.

What strategies can businesses employ to effectively select the best Incoterm for their bulk pipe orders?

Are you looking for a clear framework to select the right Incoterm4? Choosing without a proper strategy can feel like navigating blind, potentially locking you into a suboptimal deal that hurts your bottom line. Let's outline a strategic approach to making the best choice.

To select the best Incoterm for bulk pipe orders, businesses should conduct a total cost analysis beyond the unit price, evaluate their internal logistics capabilities and risk tolerance, and align the chosen term with their overall supply chain strategy, prioritizing either control (FOB) or convenience (CIF/DDP).

The key to an effective strategy is moving the Incoterm discussion from an operational afterthought to a strategic priority at the beginning of the procurement process. It should be a collaborative conversation between your procurement, logistics, and finance teams, and importantly, with your supplier. I often act as a consultant for my clients in this regard. For a construction company in the Philippines, we might analyze the trade-off between the predictable budget of a CIF contract versus the potential savings and scheduling control of FOB for their specific project timeline. For a distributor in Russia, the conversation might center on whether the high security of a DDP term outweighs its premium cost. By transforming the selection into a strategic analysis rather than a simple choice, businesses can unlock significant value. This proactive approach ensures the final decision genuinely supports the project's financial goals and the company's operational strengths, turning a potential point of friction into a source of competitive advantage.

Choosing the right Incoterm is not about finding a single "best" answer, but about developing a systematic process to find the "best fit" for each specific transaction. An effective strategy is holistic, data-driven, and adaptable. It requires an honest internal assessment and a transparent dialogue with your supplier. At MFY, we encourage our clients to adopt such a strategic mindset, as it leads to stronger, more resilient partnerships. Below are three core strategic pillars that any business sourcing bulk pipe orders can implement to navigate this critical decision with confidence and precision.

Strategy 1: Conduct a Total Cost of Ownership (TCO) Analysis

The most common mistake businesses make is comparing quotes based solely on the per-unit price. An FOB quote will always look cheaper than a CIF quote, and a CIF quote will always be cheaper than DDP. This is misleading. An effective strategy requires a shift to a Total Cost of Ownership (TCO) model5. This means you must quantify not just the product cost, but all associated costs required to get the pipes from the supplier's factory to your final destination.

To implement this, your procurement team should create a cost model. For an FOB quote from us, this model would add your own estimated or quoted costs for ocean freight, marine insurance, and any freight forwarder service fees. For a CIF quote, it would add the costs of customs clearance, port handling at your end, import duties, and inland transportation. For a DDP quote, the TCO is essentially the quoted price, but you might add a risk factor for potential delays if the supplier is unproven. For example, a client sourcing 200 tons of stainless steel pipe for a desalination plant in the Middle East might find that our CIF price is 5% higher than our FOB price. However, after they get freight quotes from their own forwarder and factor in the administrative time of their staff to manage the booking, they might discover the total cost under FOB is only 1% cheaper, but with significantly more administrative burden and risk.

This analytical approach removes guesswork from the decision. It allows for a true, apples-to-apples comparison of the different Incoterms. It transforms the conversation from "which price is lower?" to "which option delivers the best overall value and the most predictable final cost for our project?" This data-driven strategy is the bedrock of professional industrial procurement.

Strategy 2: Perform an Internal Capability and Risk Assessment

The second strategic pillar is an honest and rigorous internal assessment. The "best" Incoterm is entirely relative to your company's unique strengths, weaknesses, and risk appetite. Your team must ask a series of critical questions: Do we have an experienced in-house logistics team? Do we have established relationships with freight forwarders that give us competitive rates and reliable service? What is our risk tolerance for freight market volatility? Do our project budgets have the flexibility to absorb a sudden spike in shipping costs? How experienced are we with the customs procedures in our own country?

I saw this strategy in action with a large manufacturing client in India. As part of their annual review, they assessed their procurement process. They realized that while their logistics team was excellent at managing domestic transport, they lacked the specialized expertise and volume leverage to effectively manage international ocean freight. They made a strategic decision to shift their sourcing policy for overseas materials from FOB to CIF. They concluded that suppliers like MFY, who ship hundreds of containers globally each month, could secure more reliable service and more stable freight costs than they could on their own.

Conversely, a different client, a major engineering contractor, performed the same assessment and came to the opposite conclusion. They had recently hired a new logistics director with extensive international experience and determined they had the internal capability to take on FOB shipments to gain more control over project timelines. The strategy is not about arriving at a universal answer but about ensuring the chosen Incoterm aligns perfectly with your documented operational capabilities and your board-approved risk management framework.

Strategy 3: Foster a Collaborative Dialogue with Your Supplier

The final, and perhaps most overlooked, strategy is to treat your supplier as a partner in the decision-making process. Too often, the choice of Incoterm is dictated in a purchase order with little to no discussion. This is a missed opportunity. An experienced and transparent supplier has a wealth of knowledge about shipping routes, port conditions, and customs challenges that you can leverage. You should proactively engage your supplier in a strategic dialogue.

When a client comes to me, I encourage them to be open about their project's priorities. Is cost the absolute driver? Or is schedule predictability more important? Are they risk-averse? By understanding their core drivers, I can provide a more tailored recommendation. For example, for a shipment to a port known for congestion, I might advise that even if a client prefers FOB, allowing us to manage the freight under a CFR (Cost and Freight) or CIF term might be beneficial, as our preferred carriers may have priority berthing arrangements that can prevent costly delays.

This collaborative approach builds trust and leads to better outcomes. Ask your supplier: "Based on our order size and destination, what challenges do you foresee?" or "What are the pros and cons of FOB versus CIF for this specific shipment in the current market?" A good supplier will welcome this conversation. They want a smooth transaction just as much as you do. By leveraging your supplier's on-the-ground expertise, you add another layer of data and insight to your decision-making process, ensuring your chosen strategy is not just internally sound but also externally validated.

FOB gives buyers more controlПравда

FOB terms allow buyers to choose their own freight forwarders and have more control over shipping schedules and costs.

DDP is always cheaperЛожь

DDP includes all costs but often carries a premium price; buyers should compare total costs across Incoterms.

How can businesses optimize their logistics and cost efficiency using Incoterms 2020 in pipe trading?

Are you leaving money on the table in your pipe trading operations? Simply choosing an Incoterm is not enough; true optimization comes from actively using these rules to enhance logistical efficiency and drive down costs, giving you a distinct competitive advantage in the market.

To optimize logistics and cost in pipe trading, businesses should strategically select FOB shipping to control freight when they have volume leverage, use CIF for budget predictability on complex routes, and leverage DDP for high-value, time-sensitive deliveries, consistently reassessing the choice against current market conditions.

Optimization is an active, ongoing process, not a one-time decision. It’s about viewing Incoterms as dynamic levers within your supply chain. For many of my long-term partners, our discussion about Incoterms evolves from year to year. A distributor in Southeast Asia might use FOB for standard stock orders where they can consolidate shipments and control costs, but then switch to CIF or even DDP for a special project order with a tight, can't-miss deadline for a specific customer. This hybrid approach is the hallmark of a sophisticated procurement strategy. It demonstrates a deep understanding that logistics is not a monolithic function. We work closely with these partners, offering the flexibility they need to deploy the right term for the right job. This collaborative fine-tuning is where real, sustainable cost and efficiency gains are found, transforming the supply chain from a mere cost center into a powerful enabler of business growth.

In the competitive world of steel pipe trading, where margins can be tight and project deadlines rigid, logistical efficiency is paramount. Incoterms 2020 are not just a legal framework but a powerful toolkit for optimization. Businesses that masterfully wield these tools can significantly reduce their total costs, improve delivery predictability, and build a more resilient supply chain. The key is to move beyond a passive selection process and actively use Incoterms to exploit market opportunities and mitigate risks. This requires a nuanced understanding of how each term can be leveraged to achieve specific operational and financial objectives.

Leveraging FOB for Aggregated Freight and Carrier Negotiation

For distributors and large-scale manufacturing companies, the path to cost optimization often runs through FOB. The strategy here is freight aggregation. A single 100-ton order of stainless steel pipes may not be enough to command the lowest freight rates, but when that order is combined with three other orders from different suppliers in the same region, the buyer suddenly has the negotiating power of a 400-ton shipment. This is a classic optimization tactic used by sophisticated buyers.

To execute this, a business must have a strong relationship with a freight forwarder in the origin country. For our clients pursuing this strategy, they nominate a forwarder who then coordinates with us at MFY and their other suppliers. The forwarder consolidates the cargo at a warehouse near the port before booking it as a single, larger shipment. According to industry logistics studies, increasing shipment volume can reduce per-unit freight costs by 15-25%. This is a direct, tangible saving that flows straight to the bottom line.

Furthermore, FOB provides the freedom to choose the carrier. This allows a business to select a shipping line based on its own specific priorities. If speed is critical, they can opt for a premium carrier with a faster transit time and better on-time performance record. If cost is the absolute priority, they can choose a more economical option. This ability to tailor the logistics to the specific need—whether it's a fast-track delivery for an urgent project or a low-cost shipment for replenishing stock—is a powerful form of optimization that is only possible when the buyer controls the freight.

Using CIF for Risk Mitigation and Market Entry

While FOB is a tool for control, CIF is a powerful tool for risk mitigation and simplification, especially when entering new markets or dealing with complex trade routes. Cost optimization is not just about finding the lowest price; it's also about ensuring cost predictability. A CIF contract provides this. When we quote a CIF price to a client, we are taking on the risk of freight rate volatility. In a market where rates can surge unexpectedly, this can be a huge benefit for the buyer, allowing them to lock in a final landed cost to their port and protect their project budget from unforeseen shipping expenses.

Consider a construction contractor bidding on a project that won't start for six months. They need to secure a price for their stainless steel pipes today to finalize their bid. If they get an FOB quote, they are exposed to six months of potential freight rate increases. If they take a CIF quote from us, we lock in the transport cost, providing them with the budget certainty they need to bid competitively and confidently. This is a strategic use of CIF to de-risk the procurement process.

Moreover, for businesses expanding their sourcing footprint to a new country like China for the first time, CIF is an effective optimization tool for reducing administrative burden. It allows them to bypass the complexities of vetting and contracting with unfamiliar freight forwarders and carriers. By relying on the seller's established logistics network, they can streamline their initial transactions, allowing their team to focus on core business activities. In this context, the premium paid for CIF is an investment in simplicity and risk reduction.

Employing DDP for Time-Critical and High-Value Shipments

DDP is the ultimate optimization tool when the most valuable commodity is not money, but time and certainty. While it is the most expensive option on paper, its all-encompassing nature can provide immense value in specific, high-stakes scenarios. Think of a critical manufacturing plant shutdown where a specific set of custom-fabricated stainless steel pipes is needed for the restart. The cost of that plant being down for an extra day could be hundreds of thousands of dollars, far outweighing any potential savings on shipping.

In this scenario, DDP is the optimal choice. The buyer tasks the seller with managing the entire door-to-door process. This single point of accountability is crucial. There is no risk of hand-off errors between a freight forwarder, a customs broker, and an inland trucking company. The seller is responsible for the entire, seamless execution. We recently handled such a shipment for a client in the energy sector. A critical component had failed, and they needed replacement pipes delivered directly to their remote site. By selecting DDP, they outsourced the entire complex logistical challenge to us, confident that we would manage every step, from export to final delivery, ensuring the parts arrived with the maximum possible speed and minimum distraction for their on-site engineering team.

This strategic deployment of DDP optimizes the overall project or business outcome, not just the logistics cost. It's an understanding that the total cost of a problem (like a plant shutdown) is often far greater than the marginal cost of a premium logistics solution. Businesses that understand this can use DDP as a powerful tool to protect their core operations and ensure business continuity.

FOB enables freight cost controlПравда

FOB terms allow buyers to consolidate shipments and negotiate better freight rates by leveraging volume.

CIF eliminates freight volatilityЛожь

CIF transfers freight risk to sellers but doesn't eliminate market volatility - sellers still face rate fluctuations.

Заключение

Ultimately, choosing between FOB, CIF, and DDP is a critical strategic decision, not just a logistical one. Base your choice on a clear analysis of your company's risk tolerance, in-house capabilities, and desire for control, ensuring your supply chain is both resilient and cost-effective.

-

Discover how ICC shapes global trade with Incoterms and other regulations ↩

-

Learn about typical coverage in CIF insurance to prevent insufficient protection. ↩

-

Ensure supplier reliability in handling DDP arrangements and avoid costly delays. ↩

-

Learn about Incoterms and their role in defining shipping responsibilities and risks. ↩

-

Discover how TCO provides a comprehensive cost evaluation for effective procurement. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.