304 & 316 SS Tubing Supplier: Bulk Inventory & Rapid Delivery to India & Southeast Asia

Project delays cost money and credibility. Unreliable tubing suppliers often cause these delays. A partner with bulk stock and fast delivery is the solution to keep your projects on schedule.

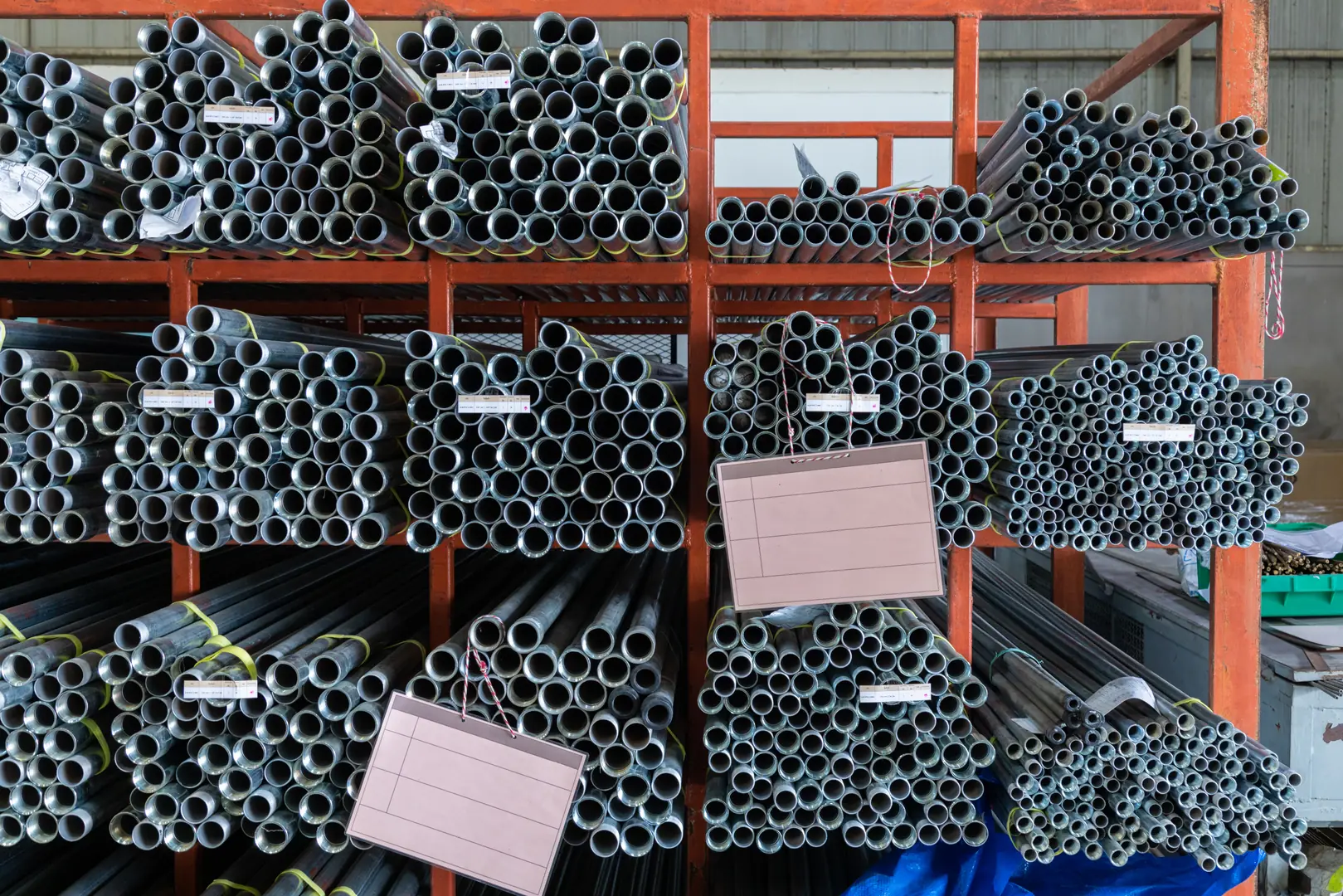

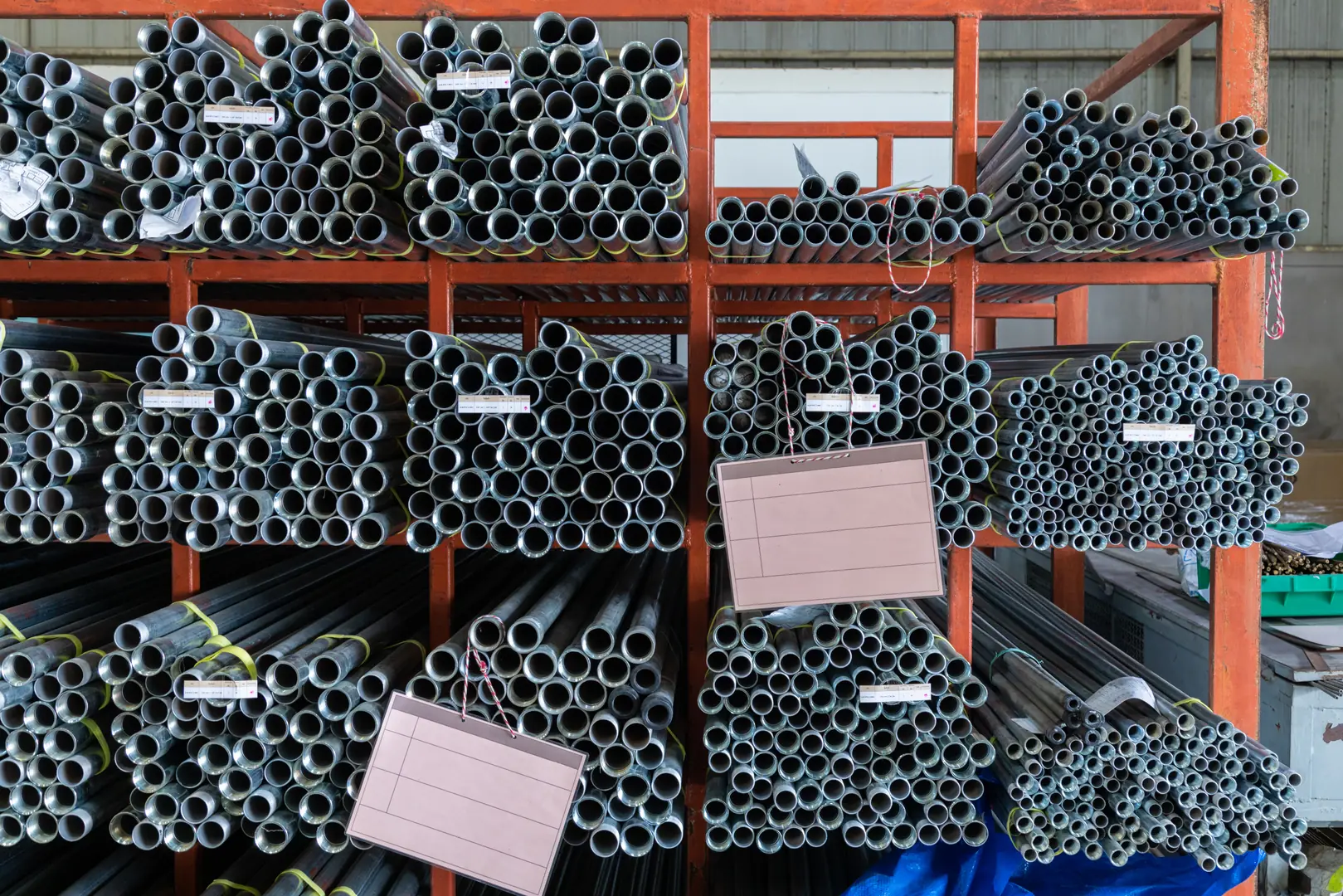

Mastering this requires a fully integrated supply chain, strategic warehousing, and advanced logistics. By holding significant bulk inventory of 304 and 316 tubing and optimizing delivery routes, a supplier can guarantee reliability and speed to high-growth markets like India and Southeast Asia.

As someone who has spent years navigating the global stainless steel market, I've seen firsthand how a reliable supply chain can make or break a major project. It's not just about the quality of the steel; it's about getting that quality product to your site exactly when you need it. In rapidly developing regions like India and Southeast Asia, the stakes are even higher. Let's explore the dynamics of this market and what it truly takes to be a dependable supplier.

Why is the demand for 304 & 316 stainless steel tubing growing in India & Southeast Asia?

Expanding operations is tough when sourcing quality materials is a constant struggle. Understanding market demand helps you secure the right stainless steel tubing for growth and avoid costly shortages.

Demand is driven by rapid industrialization, massive infrastructure projects, and a growing manufacturing sector. These regions need corrosion-resistant and durable materials like 304 and 316 stainless steel for everything from construction to food processing, fueling consistent high demand.

The growth story of India and Southeast Asia is remarkable. I travel to these regions frequently, and the pace of development is incredible. This isn't just about building new skyscrapers; it's a fundamental transformation of their industrial base. This boom directly translates into an enormous appetite for high-quality stainless steel tubing. We're not just a supplier; we are a partner in this growth. I remember a client in Vietnam who was building a new food processing facility. They needed 316 tubing urgently to meet their launch deadline. Their local options were limited and couldn't guarantee the volume. We were able to dispatch their required bulk order from our ready inventory, ensuring their project stayed on track. This is a common story. The reliability of materials like 304 and 316 is critical for long-term infrastructure, and businesses know they can't afford to compromise.

Key Sectors Driving Demand

The need for 304 and 316 tubing is diverse, touching almost every part of the economy. In infrastructure, it's essential for water treatment plants and transportation systems where corrosion resistance[^1] is paramount. In manufacturing, sectors like automotive, pharmaceuticals, and food and beverage rely on the hygienic and durable properties of stainless steel.

| Класс | Primary Application in the Region | Key Benefit |

|---|---|---|

| 304 SS Tubing | General construction, automotive parts, kitchen equipment | Excellent formability and general corrosion resistance |

| 316 SS Tubing | Chemical processing, marine hardware, medical devices | Superior corrosion resistance, especially against chlorides |

What are the current supply chain dynamics for stainless steel tubing in these markets?

Navigating the supply chain is complex. Local and international players create a confusing landscape. Understanding these dynamics helps you choose the most reliable and efficient sourcing partner for your needs.

The current dynamics involve a mix of local manufacturing and heavy reliance on imports, especially from China. This creates a competitive but often fragmented market, where logistical efficiency, import duties, and supplier reliability are the key factors that determine success for buyers.

The supply chain in this region is a fascinating puzzle. While local production is growing, it often struggles to meet the sheer scale and stringent quality standards required for major industrial projects. This is where global suppliers like MFY come in. We bridge that gap. However, simply shipping from China is not enough. The real challenge lies in navigating the "last mile." I recall working with a new distributor in India who was struggling with inconsistent delivery times from other suppliers. They were losing business because they couldn't give their customers firm commitments. We worked with them to establish a streamlined logistics flow, leveraging our strong relationships with freight forwarders and customs brokers. By understanding the local logistical chokepoints and having a plan to bypass them, we turned their biggest weakness into a competitive strength. It's this deep understanding of the local landscape, combined with global production power, that defines a truly effective supply chain partner.

Local Sourcing vs. Integrated Global Supply

Many companies are tempted by local sourcing, but it can be a double-edged sword. While it may seem simpler, local suppliers can face limitations in raw material access, technology, and scale. An integrated global supplier, on the other hand, controls the entire process from raw material smelting to final product delivery. This integration provides unparalleled control over quality, cost, and, most importantly, availability. It removes layers of uncertainty for the end-user.

What challenges do suppliers face with bulk inventory and rapid delivery?

You need tubing now, but it's unavailable. This common problem halts production and inflates costs. Understanding a supplier's challenges reveals who is truly equipped to serve you reliably.

Key challenges include managing high capital costs for large inventories, navigating complex cross-border logistics, and forecasting fluctuating demand accurately. Price volatility of raw materials like nickel and chromium further complicates maintaining a stable and readily available supply.

Holding millions of dollars worth of stainless steel tubing in a warehouse is not for the faint of heart. It's a significant financial commitment. The price of nickel can swing wildly, directly impacting our costs. If we don't manage this risk carefully, it gets passed on to our clients. Beyond the financial aspect, there's the operational complexity. Forecasting demand across multiple countries, each with its own economic cycles and project pipelines, is a massive data challenge. Then comes logistics. A shipment can face delays at customs, port congestion, or inland transportation issues. A supplier who simply takes an order and hopes for the best is not a real partner. At MFY, we see these challenges not as problems, but as areas where we can create value. Our scale allows us to absorb raw material price shocks, and our integrated model gives us the data we need for accurate forecasting. We don't just react; we anticipate.

| Вызов | MFY's Solution |

|---|---|

| High Capital Cost | Economies of scale from our fully integrated supply chain. |

| Demand Volatility | Data-driven forecasting and agile production scheduling. |

| Logistical Complexity | Strong local partnerships and strategic regional warehousing. |

| Price Fluctuations | Strategic raw material sourcing and risk management. |

What strategies can solve supply and delivery challenges for stainless steel tubing?

Supply disruptions are a constant threat. Waiting weeks for materials is not an option for any serious business. A proactive strategy combining inventory management and logistics is the only way to win.

Effective strategies include establishing regional warehousing hubs, leveraging a fully integrated supply chain from raw material to final product, and forming strong partnerships with local logistics providers. This hybrid model ensures both bulk availability and agile, rapid last-mile delivery.

The solution is to think globally but act locally. Our core strategy at MFY is built on this principle. We don't just ship from a massive central facility in China. Instead, we are building a network of regional distribution hubs closer to our key markets. This "hub-and-spoke" model allows us to hold substantial inventory in the region, dramatically cutting down delivery times from weeks to days. I was personally involved in setting up a new logistics partnership in Indonesia last year. By working with a trusted local provider, we were able to cut final delivery times to our clients in Jakarta by nearly 40%. This is the power of combining our production strength with local expertise.

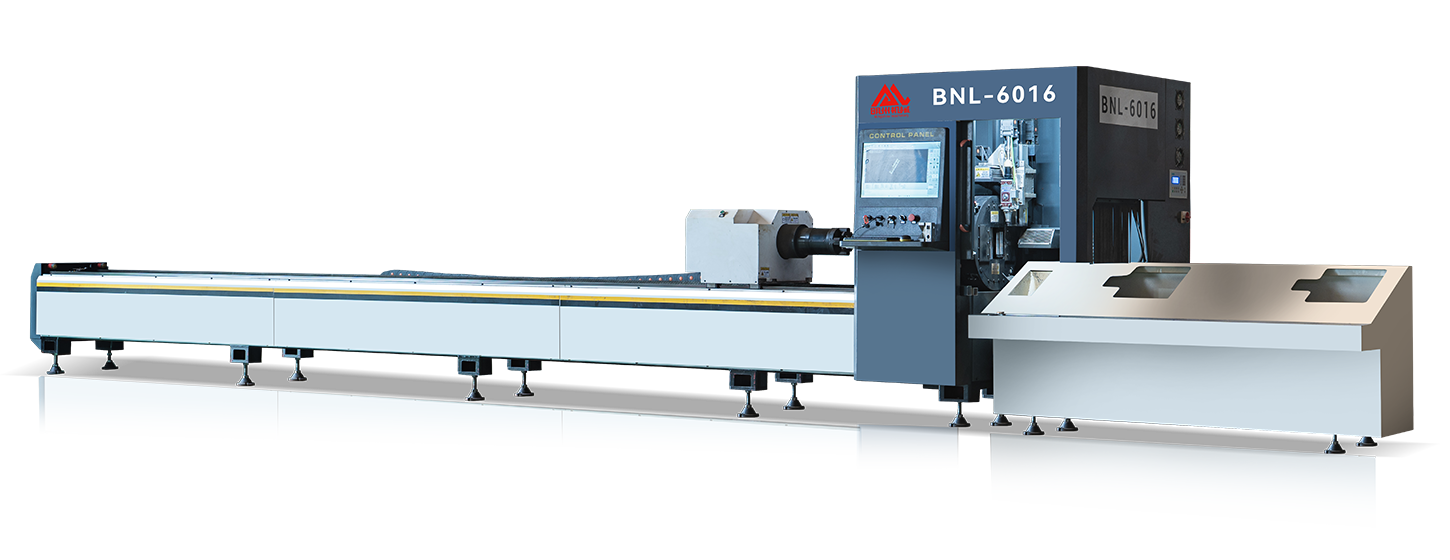

The Power of Vertical Integration

Our greatest strategic advantage is our vertical integration[^2]. Because we control everything from the raw materials to the finished tubing, we have an unmatched level of control over the supply chain. We aren't waiting on another company for our raw inputs, so we can adjust production schedules with incredible agility. This integration allows us to maintain our bulk inventory levels consistently. For our clients, this means they aren't just buying a product; they are buying certainty. They know that when they place an order with MFY, the product is available and the delivery timeline is reliable.

How are technological innovations enhancing the stainless steel tubing supply chain?

Manual tracking is slow and prone to errors. This lack of visibility creates uncertainty and risk. Technology offers the transparency and efficiency you need to trust your supply chain partner.

Innovations like real-time inventory management systems, AI-powered demand forecasting, and digital platforms for order tracking are revolutionizing the supply chain. This technology provides complete transparency, reduces lead times, and allows for more agile responses to market changes.

In today's world, data is as important as steel. We have invested heavily in building a digital backbone for our entire supply chain. Our clients can log into our platform and see real-time inventory levels for 304 and 316 tubing. They can place an order and track its journey from our warehouse to their doorstep, all from their computer or phone. This isn't just about convenience; it's about building trust through transparency. Internally, we use AI and machine learning to analyze market data, helping us predict demand surges before they happen. This allows us to proactively adjust our inventory and production, ensuring we are always ready to meet our clients' needs. Technology transforms us from a reactive supplier into a proactive, predictive partner.

Traditional vs. Tech-Enabled Supply Chain

The difference is night and day. The old way of doing business involved endless phone calls, emails, and uncertainty. The new way is about instant access to information and data-driven decisions.

| Function | Traditional Method | Tech-Enabled Method (MFY) |

|---|---|---|

| Inventory Check | Phone call/email, 24-hour delay | Real-time online portal, instant access |

| Order Tracking | Vague updates from freight forwarder | Live GPS tracking from warehouse to site |

| Demand Planning | Based on historical sales, guesswork | AI-powered forecasting based on market data |

Заключение

In today's fast-paced markets, success depends on more than just materials. It requires a supply partner who masters bulk inventory and rapid delivery. At MFY, we are that partner, committed to fueling your growth in India and Southeast Asia with reliability and speed.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.