Pharmaceutical-Grade Tubing: ISO 14644 & GMP Compliance Explained

Are you navigating the complex web of pharmaceutical manufacturing standards? The risk of non-compliance, leading to contamination, costly batch recalls, and severe regulatory penalties, is a constant pressure. Understanding the intricacies of ISO 14644 and GMP is your first line of defense in ensuring product purity.

Pharmaceutical-grade tubing compliance is achieved by adhering to ISO 14644 standard for cleanroom air quality and Good Manufacturing Practices (GMP) for consistent production control. This dual approach ensures tubing is free from contaminants, meeting the stringent safety and efficacy standards required in pharmaceutical applications.

This landscape of regulations can appear daunting, but it provides a clear roadmap to quality and safety. For anyone involved in the pharmaceutical supply chain—from engineering contractors to equipment integrators—mastering these standards is fundamental. It transcends mere rule-following; it is about safeguarding patient health and cementing a reputation for unwavering quality. Let's explore how these critical standards shape our industry and your operations.

The entire pharmaceutical sector is built on a foundation of absolute trust, where the margin for error is effectively zero. In this context, tubing, though a seemingly simple component, serves as a critical pathway for highly sensitive materials, where any failure can lead to catastrophic results. Viewing compliance with ISO 14644 and GMP not as a regulatory burden but as a strategic imperative is key. Reports from bodies like the FDA consistently show that contamination-related recalls cost the industry billions annually. At MFY, we believe that investing in superior quality tubing is an investment in risk mitigation, brand integrity, and long-term market leadership. This represents a crucial shift from a cost-focused mindset to a value-centric approach, where the upfront investment in compliant components prevents far greater downstream losses and liabilities.

The Critical Role of Pharmaceutical-Grade Tubing

Do you ever underestimate the role of simple tubing in your complex pharmaceutical processes? This oversight can be perilous, as a single component's failure can compromise entire product batches, resulting in immense financial loss, regulatory action, and lasting damage to your brand's reputation.

Pharmaceutical-grade tubing is essential for preserving the sterility and chemical integrity of fluids throughout the drug manufacturing process. Its importance is rooted in preventing microbial and particulate contamination, ensuring product purity, and adhering to strict regulatory standards that guarantee patient safety and therapeutic efficacy.

The journey of any pharmaceutical product, from initial formulation to the final packaged good, is a gantlet of potential contamination risks. Every single surface that comes into contact with the product must be impeccably clean, non-reactive, and non-leaching. This is where pharmaceutical-grade tubing, typically crafted from high-purity stainless steel like 316L1, proves its worth as an indispensable component of the quality assurance framework. Its function is far more than simple fluid conveyance; it is an active guardian of product integrity. I recall a client in Southeast Asia, a prominent insulin manufacturer, who was battling inconsistent batch quality. The root cause was not their formulation or processing but microscopic imperfections and residual contaminants within their tubing system. These flaws were causing trace elements to leach into their product. By transitioning to MFY’s certified pharmaceutical-grade tubing, which features a superior internal surface finish, they not only stabilized their product quality but also enhanced their production yield by nearly 5%. This experience powerfully illustrates that investing in the right infrastructure isn't merely an operational expense; it is a direct and measurable contributor to profitability and, most importantly, patient safety.

From Raw Material to Sterile Conduit: The Tubing Lifecycle

The journey to creating compliant pharmaceutical tubing begins with the uncompromising selection of raw materials. For most applications, 316L stainless steel is the material of choice due to its specific metallurgical properties. The "L" denotes low carbon content (typically below 0.03%), which minimizes carbide precipitation during welding. This is critical for preventing intergranular corrosion, a potential site for microbial colonization and contamination. Furthermore, the inclusion of molybdenum (typically 2-3%) significantly enhances its resistance to chloride corrosion, a common threat in many pharmaceutical processes involving saline solutions or cleaning agents. At MFY, we don't just accept a supplier's declaration; we enforce a strict qualification process that includes independent verification of the material's chemical composition.

Traceability is the unbreakable thread that runs through the entire lifecycle. In the GMP environment, the principle "if it wasn't documented, it didn't happen" is paramount. Every length of our pharmaceutical-grade tubing is accompanied by a Mill Test Certificate (MTC or MTR) that traces it back to the specific heat or lot of steel from which it was made. This document provides a detailed chemical and physical analysis. I remember a situation with an engineering contractor client in India who was commissioning a new vaccine production facility. During a pre-validation audit, the regulator requested full traceability for a specific section of the high-purity water system. Because of our robust documentation protocol, we were able to provide the complete material history within hours, satisfying the auditor and keeping the project on schedule. This level of granular documentation is not a "nice-to-have"; it is an absolute requirement for our clients' validation packages and their license to operate.

The manufacturing process itself is where material potential is transformed into functional quality. We primarily produce seamless tubing for pharmaceutical applications, as this construction method eliminates the longitudinal weld seam found in standard welded tubing. A seam, no matter how well-made, can be a potential crevice—a microscopic trap for bacteria and process residues that is difficult to clean and sterilize. The final, critical step is finishing the internal surface. This is achieved through processes like electropolishing, which electrochemically removes a microscopic layer of material, resulting in an exceptionally smooth, passive, and cleanable surface. This process significantly reduces the surface roughness (Ra), which is a key specification for preventing microbial adhesion and protein denaturation.

The Cost of Contamination: A Business Perspective

The financial consequences of contamination in pharmaceutical manufacturing are severe and multifaceted. The most immediate and visible costs are the direct losses from a rejected batch. This includes the cost of the raw materials, the energy consumed, the labor invested, and the safe disposal of the compromised product. For high-value biologics, a single lost batch can represent millions of dollars in lost revenue. A 2022 industry report estimated that product recalls, often stemming from contamination or sterility issues, cost the pharmaceutical sector an average of $2.5 billion to $5 billion annually, a figure that continues to rise with the complexity of modern drugs.

Beyond these direct financial hits, the indirect costs can be even more damaging to an enterprise. A product recall erodes trust among patients, physicians, and regulatory bodies. Rebuilding a brand's reputation for quality and safety is an arduous and expensive undertaking that can take years. I worked with a company that had to issue a recall due to particulate matter traced back to a faulty component from a previous, non-specialized supplier. While they managed the recall efficiently, their stock price dipped, and they faced intensified scrutiny from regulators for months afterward. This experience led them to re-evaluate their entire supply chain, and they came to us at MFY specifically because they needed a partner who understood the stakes and could provide the documented assurance of quality required to rebuild that trust. The cost of our premium tubing was insignificant compared to the potential cost of another failure.

The regulatory impact of a contamination event extends far beyond a single product recall. It can trigger FDA 483 observations, warning letters, and in severe cases, a consent decree that puts a halt to production altogether. The ensuing remediation process is exhaustive, requiring a complete overhaul of systems, retraining of personnel, and extensive re-validation, all under the watchful eye of the regulatory agency. This not only incurs massive direct costs but also represents a significant opportunity cost, as the facility cannot produce commercial products. This is why we emphasize to our distributor and contractor clients that providing the cheapest component is a disservice to the end-user. The true value lies in providing a compliant, reliable product that mitigates these catastrophic business risks.

| Feature | Standard Industrial Tubing | MFY Pharmaceutical-Grade Tubing |

|---|---|---|

| Material | Often 304 Stainless Steel | 316L Stainless Steel with controlled Sulfur |

| Traceability | Basic or non-existent | Full material traceability with MTC 3.1 |

| Surface Finish (ID) | Standard mill finish | Electropolished, Ra < 0.5 µm (or as specified) |

| Manufacturing | Often welded, standard tolerance | Seamless construction, tight dimensional tolerances |

| Cleaning & Packaging | Basic cleaning, unprotected | Cleanroom cleaned, passivated, double-bagged |

| Documentation | Certificate of Conformance (optional) | Comprehensive package (MTC, Ra report, etc.) |

The Unseen Impact on Therapeutic Efficacy

The quality of pharmaceutical tubing has a direct, though often unseen, impact on the efficacy of the final drug product, particularly with sensitive biologics like monoclonal antibodies, vaccines, and cell therapies. The internal surface roughness, measured in Ra (Roughness Average), is a critical parameter. A rougher surface provides more area for proteins to adhere to and potentially denature. When a complex protein unfolds and changes its structure, it loses its therapeutic effect. This means that even if the drug is chemically pure, its biological activity can be compromised by its passage through a suboptimal tubing system, a factor that can be frustratingly difficult to pinpoint in development.

Furthermore, the phenomena of leaching and extractables pose a significant risk. Leaching refers to substances that migrate from the tubing material into the fluid under normal process conditions, while extractables are compounds that can be drawn out under more aggressive conditions (e.g., using strong solvents). These substances can be metal ions or residual compounds from the manufacturing process. In the best-case scenario, they are inert impurities; in the worst-case, they can be toxic, or they can interact with the active pharmaceutical ingredient (API), reducing its stability and shelf life. GMP regulations mandate extensive studies on extractables and leachables for any product-contact surface to ensure they are well below safe limits.

I can share a powerful example from our work with a biopharmaceutical startup. They were developing a promising monoclonal antibody but encountered issues with product aggregation and loss of potency during pilot-scale production. After investigating every aspect of their process, they suspected their fluid pathway. We partnered with them to replace their existing tubing with our electropolished 316L tubing, which has a certified internal surface roughness of less than 0.4 µm Ra. The result was immediate and dramatic: protein aggregation was significantly reduced, and product stability improved, allowing them to proceed confidently to their next round of clinical trials. This case highlights that the tubing is not just a pipe; it is a critical piece of process equipment that directly influences the quality and efficacy of the final medicine.

316L stainless steel prevents corrosionTrue

316L stainless steel's low carbon content and molybdenum addition enhance its resistance to chloride corrosion, making it ideal for pharmaceutical applications.

Welded tubing is better for pharmaceuticalsFalse

Seamless tubing is preferred as welded tubing's seams can trap bacteria and residues, compromising sterility and cleanability.

Demystifying the Core Regulations: ISO 14644 and GMP

Are you struggling to differentiate between the myriad of pharmaceutical regulations? The complex terminology of standards like ISO 14644 and GMP can be a barrier, yet misinterpreting their requirements can lead directly to failed audits, costly rework, and disruptive production shutdowns that halt your business.

ISO 14644 is a standard that specifies the classification of air cleanliness in cleanrooms based on airborne particle counts. In contrast, Good Manufacturing Practices (GMP) provide a holistic quality assurance system to ensure products are consistently produced and controlled according to rigorous standards.

While ISO 14644 and GMP are separate standards, in the world of sterile manufacturing, they are inextricably linked. I often advise my clients to think of it this way: ISO 14644 defines the "stage"—the controlled, clean environment where work must be performed—while GMP dictates the "performance"—the documented procedures, trained personnel, and quality checks that take place on that stage. You simply cannot claim GMP compliance for a sterile product if it is not manufactured and handled in an environment that meets a specific ISO cleanroom classification. For a component like pharmaceutical tubing, this dual compliance is non-negotiable from the moment of its final cleaning and packaging to its installation and use. I have seen many projects, particularly in emerging markets, where there is a heavy focus on the primary processing equipment, while the standards for ancillary components like tubing are underestimated. This often becomes a major bottleneck during the final system qualification and validation phase, causing costly delays. A thorough understanding of how these two standards work in tandem is crucial for a smooth and successful project execution.

ISO 14644: Mastering the Controlled Environment

ISO 14644, specifically Part 1, provides a standardized system for classifying the cleanliness of air in cleanrooms and other controlled environments. This classification is based on the number and size of airborne particles per cubic meter of air. The classes range from ISO 1 (the cleanest) to ISO 9 (the least clean, but still cleaner than a typical room). For pharmaceutical manufacturing, the most relevant classes are typically ISO 5 through ISO 8. For example, an ISO 7 cleanroom, a common environment for many support activities, must have fewer than 352,000 particles (at 0.5 µm size) per cubic meter. An ISO 5 environment, required for the most critical aseptic processes, has a limit of just 3,520 particles.

This standard directly impacts the final stages of pharmaceutical tubing production and handling. At MFY, the final cleaning, passivation, and packaging of our pharmaceutical-grade tubing are performed within a certified cleanroom environment. This critical step ensures that the pristine, electropolished internal surface is not compromised by airborne contaminants before it is securely sealed. The tubing is then typically double-bagged, with the inner bag being cleanroom-grade material. This allows the outer bag to be removed upon entry into the client's cleanroom warehouse, and the inner bag to be removed just before installation, maintaining a chain of cleanliness.

Our role extends beyond manufacturing to advising our clients on best practices. We frequently consult with engineering and construction contractors on how to handle our products on-site. The most meticulously manufactured tube can be instantly contaminated if it's unbagged in an uncontrolled environment or cut with tools that introduce particulates. We provide clear protocols for on-site handling, cutting, and preparation to ensure the cleanliness we establish in our facility is maintained all the way to the final weld. This proactive guidance demonstrates our commitment to the end-to-end success of our clients' projects, reinforcing our position as a partner rather than just a supplier.

GMP: The Blueprint for Quality and Consistency

Good Manufacturing Practices (GMP) represent a holistic philosophy of quality assurance. Unlike a standard that focuses on a specific element like air quality, GMP covers every aspect of the production process. Its fundamental principle is that quality cannot be tested into a final product; it must be built into every step of the manufacturing process. For a tubing manufacturer, this means implementing rigorous controls from the moment raw materials arrive until the final product is shipped. This encompasses validated manufacturing processes, stringent in-process quality checks, calibrated equipment, and highly trained personnel.

Documentation is the backbone of GMP. A core tenet is that every action must be documented, providing a complete and auditable trail. If an action isn't documented, regulators assume it never happened. This is why, at MFY, every batch of our pharmaceutical tubing is shipped with a comprehensive documentation package. This isn't just a simple certificate of conformance. It includes the full Mill Test Certificate (MTC) for material traceability, detailed reports on the internal surface roughness (Ra) measurements, and confirmation of processes like passivation. This documentation is not just for our records; it is an essential component of our clients' Validation Master Plan (VMP) and is critical for satisfying regulatory audits.

Let me share a client story that illustrates this point perfectly. A distributor we work with in the Middle East received an urgent request from their customer, a local pharmaceutical manufacturer, who was undergoing a surprise regulatory inspection. The inspector had requested complete traceability and quality documentation for the high-purity water loop installed the previous year. Because our GMP-aligned processes ensure that this documentation is systematically generated and archived for every order, we were able to retrieve and transmit the full package—MTCs, Ra reports, and certificates—within two hours. This rapid response enabled our distributor to satisfy the auditor immediately, reinforcing their reliability and strengthening their relationship with their end customer. This is the practical, real-world value of a robust, GMP-driven quality system.

The Synergy: How ISO 14644 and GMP Intersect for Tubing

For sterile pharmaceutical applications, ISO 14644 and GMP are not independent systems; they are deeply synergistic and mutually reinforcing. You cannot achieve GMP's requirement for sterility assurance without leveraging the controlled environments defined by ISO 14644. GMP regulations state that sterile products must be produced in a manner that prevents microbial and particulate contamination. ISO 14644 provides the specific, measurable, and internationally recognized standard for what constitutes a suitably controlled environment for those activities. It gives teeth to the principles of GMP.

Consider the critical process of orbital welding, which is used to join sections of stainless steel tubing on-site during the construction of a pharmaceutical facility. A GMP-compliant approach dictates that the welding process must be validated, the equipment must be calibrated, and the operator must be certified. However, this perfectly executed weld could be instantly compromised if performed in a dusty, uncontrolled environment where airborne particles could land on the molten weld pool, creating inclusions and defects. This is where ISO 14644 comes in. The best practice, driven by this synergy, is to perform such welds within a controlled space, often using portable clean zones or ensuring the entire construction area meets a specific ISO classification. This ensures the integrity of the weld, both mechanically and in terms of cleanliness.

This interdependent relationship extends across the entire supply chain, creating a continuous chain of custody for quality. As the component manufacturer, MFY is responsible for ensuring our production environment meets the required ISO class and our processes align with GMP principles. When we deliver our double-bagged, certified tubing, we are handing off that responsibility. Our clients—the engineering contractors and equipment integrators—must then uphold these standards during storage, handling, and installation. Their GMP-compliant installation procedures must be executed within an appropriately classified ISO environment to deliver a final system that the end-user, the pharmaceutical manufacturer, can successfully validate. It is a shared responsibility, and our role is to provide a flawlessly compliant starting point.

ISO 14644 classifies cleanroom air cleanlinessTrue

ISO 14644 Part 1 specifically defines cleanroom classifications based on airborne particle counts per cubic meter.

GMP only applies to final product testingFalse

GMP requires quality to be built into every manufacturing step, not just tested at the end.

Common Compliance Challenges Faced by Manufacturers

Are you aware of the hidden pitfalls in maintaining tubing compliance? Beyond the obvious, subtle challenges in material sourcing, surface integrity, and documentation can create significant compliance gaps, exposing your operations to the risk of regulatory action and production delays if not proactively managed and addressed.

Common compliance challenges include ensuring complete material traceability from the mill to the final installation, consistently maintaining the specified internal surface finish (Ra), preventing contamination during transport and handling, and managing the comprehensive documentation required for validation and audits.

Navigating these challenges requires more than just good intentions; it demands a robust quality system and a deep understanding of the regulatory landscape. The complexities begin with the raw material itself—verifying its origin and composition is a non-trivial task that demands a rigorous supplier qualification process. Even with the best material, maintaining the delicate, electropolished internal surface of the tubing through every stage of handling, fabrication, and installation is a significant logistical challenge. A single scratch can compromise the entire system. I've personally seen projects delayed by weeks because tubing was improperly stored on a construction site, leading to surface contamination that required costly and time-consuming remediation. Furthermore, the administrative burden of generating, managing, and retrieving the precise documentation needed for validation can be overwhelming for teams that are not equipped with the right systems. Addressing these challenges head-on is a hallmark of a mature and reliable manufacturing operation.

The Hidden Risks in Material Sourcing and Traceability

One of the most fundamental yet challenging aspects of compliance is ensuring the absolute integrity of the raw material. The global supply chain for stainless steel2 is vast and complex, and without stringent controls, it's possible for materials with incorrect specifications or fraudulent documentation to enter the supply stream. Relying solely on a supplier's paperwork without independent verification is a significant risk. For pharmaceutical applications, specifying 316L is not enough. We must also control other elements, such as sulfur content. A higher sulfur content can improve machinability but is detrimental to weld quality and corrosion resistance, making it unsuitable for high-purity systems. This is a nuance often missed by general steel suppliers.

At MFY, we mitigate this risk through a multi-pronged strategy. Our supplier qualification process is exhaustive, involving on-site audits and a deep dive into their quality control systems. We don't just order "316L"; we provide a detailed chemical specification, including a low maximum sulfur content. Upon receipt of raw materials, we don't just file the supplier's MTC. We perform our own Positive Material Identification (PMI) using X-ray fluorescence (XRF) analyzers to verify the alloy composition of incoming stock. This provides an independent check that ensures the material we use is exactly what it's supposed to be.

The challenge of traceability is maintaining an unbroken chain of information. This means that every single piece of tubing must be linked back to its specific raw material batch and the associated MTC. This requires meticulous record-keeping and physical marking of the products. A lapse in this chain can have severe consequences. Imagine a scenario where a manufacturer discovers a flaw in a specific batch of steel. Without perfect traceability, a supplier would have no way of knowing which clients received tubing made from that batch, potentially necessitating a massive, precautionary recall. Our system ensures we can pinpoint the exact destination of every piece of tubing, turning a potential catastrophe into a manageable, targeted action.

Maintaining Surface Integrity from Factory to Installation

The internal surface finish of pharmaceutical tubing is one of its most critical attributes, and also one of its most fragile. An electropolished surface with a low Ra value is smooth on a microscopic level, but it can be easily damaged by improper handling, cutting, or storage. A scratch, no matter how small, disrupts the passive layer and creates a potential site for corrosion or bacterial biofilm formation, rendering the tube non-compliant. This challenge is magnified because the tubing passes through many hands—our production team, shipping personnel, warehouse operators, and the on-site installation crew.

To combat this, our process controls extend all the way to final packaging. After final cleaning and inspection inside our cleanroom, tubes are capped on both ends with protective, cleanroom-grade caps. They are then sealed in the inner bag, which is then placed inside a durable outer bag. This double-bagging system not only maintains cleanliness but also provides physical protection. We also utilize robust crating and packaging materials designed to prevent damage during international shipping, which can be a turbulent journey.

However, our responsibility doesn't end when the product leaves our factory. We invest heavily in educating our clients. I often have calls with the project managers of engineering firms to walk them through our recommended on-site handling procedures. We provide guidance on the correct tools for cutting (e.g., specialized orbital saws, not abrasive wheels that embed particles), proper deburring techniques, and the importance of keeping the tubes capped and protected until the moment of installation. A client in Russia once faced an issue where their installation team was using standard pipe-fitting tools, causing minor scratches. After a consultation and retraining session based on our guidelines, they were able to adjust their process and meet the stringent validation requirements without issue.

The Documentation and Validation Quagmire

In the regulated pharmaceutical industry, the physical product and its documentation are of equal importance. A perfectly manufactured tube without the correct, complete, and accurate documentation is effectively useless for a GMP application. The challenge for many manufacturers is the sheer volume and complexity of the required paperwork. This isn't just about providing an MTC; it's about supplying a comprehensive turnover package (TOP) that includes surface roughness reports, passivation certificates, welding logs (if applicable), and a final certificate of conformity that ties everything together.

Managing this data for thousands of orders and components can quickly become a quagmire if not handled systematically. Manual or paper-based systems are prone to errors, lost documents, and slow retrieval times. This is where MFY's investment in digital innovation becomes a key competitive advantage. We utilize a centralized digital quality management system (QMS) that links every production order to its full suite of documentation. When an order is completed, the system automatically collates all relevant reports and certificates into a digital package.

This digital-first approach provides immense value to our clients. For one, it guarantees that the documentation is complete and accurate every time. Secondly, it allows for near-instant retrieval. When a client, like the one I mentioned in the Middle East, needs their documentation for an audit, we don't have to search through filing cabinets. We can query our system and have the complete package ready in minutes. This level of efficiency and reliability simplifies their validation process, reduces their administrative burden, and gives them confidence when facing regulatory scrutiny. It transforms the documentation challenge from a potential bottleneck into a streamlined, value-adding process.

Material traceability is crucialTrue

Complete traceability from raw material to final installation is essential for compliance and recall management.

Surface finish can't be repairedFalse

While damaged surfaces are problematic, proper remediation techniques can often restore compliance.

Strategies for Ensuring ISO 14644 & GMP Compliance in Tubing Production

Are you searching for a reliable path to compliance? Simply hoping for the best is not a strategy. Non-compliance is a critical business threat, and proactively implementing robust strategies is the only way to ensure your tubing meets the stringent demands of the pharmaceutical industry.

Effective strategies include a multi-layered approach: rigorous supplier qualification, comprehensive in-process and final quality control, continuous employee training on GMP and cleanroom protocols, and maintaining a robust, audit-proof documentation system to ensure full traceability and transparency.

A successful compliance strategy is not a single action but an integrated system woven into the fabric of the organization's culture. It begins with the conviction that quality is everyone's responsibility. At MFY, we build our strategy on three pillars: prevention, detection, and correction. The first pillar, prevention, is the most critical; it involves designing processes and qualifying suppliers in a way that prevents defects from occurring in the first place. This includes everything from defining precise raw material specifications to designing our cleanroom workflow to minimize contamination risk. The second pillar, detection, involves deploying a comprehensive suite of testing and inspection protocols at every critical stage of production. This ensures that any deviation from our standards is caught and addressed immediately, long before it can reach the final product. The final pillar, correction, involves a robust CAPA (Corrective and Preventive Action) system, ensuring that when a deviation is detected, we not only fix the immediate issue but also analyze the root cause to prevent it from ever happening again.

Implementing a Vendor Qualification and Raw Material Control Program

The foundation of a compliant tube is a compliant raw material. Therefore, the most effective strategy begins before the steel even enters our facility. A reactive approach of simply testing incoming material is insufficient; a proactive vendor qualification program is essential. This strategy involves moving beyond a transactional relationship with suppliers to a true partnership based on verified quality. At MFY, our qualification program includes rigorous initial assessments, including on-site audits of our suppliers' mills3 to evaluate their own quality systems, production capabilities, and process controls. We don't just take their word for it; we verify their ability to consistently meet our demanding specifications.

Once a supplier is approved, the control does not stop. For every single heat of steel they provide, we demand a detailed Mill Test Certificate (MTC 3.1 under EN 10204), which provides a full chemical breakdown and report of mechanical properties. This is our first layer of verification. The second layer is our own independent testing. We use portable XRF analyzers to conduct Positive Material Identification (PMI) on incoming raw materials. This ensures that the alloy composition is precisely what we ordered, guarding against material mix-ups or fraudulent certifications. This two-gate system—supplier verification plus independent testing—provides the robust control necessary to build a foundation of unimpeachable material quality.

This stringent control program offers immense security to our clients. An equipment integrator in Southeast Asia was developing a new line of bioreactors and needed absolute certainty about the materials of construction for their end client, a major global pharmaceutical company. They chose to partner with us specifically because our transparent and rigorous material control program gave them the evidence they needed to satisfy their client's demanding quality audit. They didn't have to just trust; they could verify. This is the assurance that a proactive material control strategy delivers.

Integrating Quality Control Throughout the Production Cycle

A common mistake is to view quality control as a final inspection step. A true GMP-aligned strategy integrates quality checks throughout the entire production cycle. This in-process control allows for the immediate identification and correction of deviations, preventing waste and ensuring that the final product is built correctly from the start. It’s a strategy of continuous verification, not just final validation. For tubing production, this means checkpoints are established at every critical transformation stage.

Our process begins with the verification of the raw hollow tube's dimensions and surface. After the drawing and annealing processes, which are critical for achieving the correct dimensions and metallurgical properties, we conduct another round of checks. The most intensive quality control occurs after the electropolishing stage. Here, we conduct multiple tests: surface roughness (Ra) is measured using a profilometer at several points along the tube's length to ensure uniformity. Visual inspection under high-intensity light is performed to check for any surface anomalies like pitting or scratches. We also conduct dimensional checks again to ensure the electropolishing process hasn't altered the tube's dimensions outside of its specified tolerance.

This multi-stage inspection strategy ensures that by the time a tube reaches the final cleaning and packaging stage, we have a high degree of confidence in its quality. This stands in stark contrast to a system where a tube might go through the entire production process only to be rejected at the final QC step, which is inefficient and costly. Our integrated QC strategy is a cornerstone of our operational efficiency and a key reason we can consistently deliver high-quality products. It transforms quality control from a gatekeeper into a continuous feedback loop that drives process improvement.

The Role of Employee Training and a Quality-Centric Culture

The most sophisticated equipment and processes are only as effective as the people who operate them. Therefore, a cornerstone of any compliance strategy is a relentless focus on employee training and the cultivation of a quality-centric culture. Every employee, from the machine operator to the packaging technician, must understand not just what they are doing, but why they are doing it—specifically, how their actions directly impact patient safety and product quality. This understanding is crucial for ensuring adherence to Standard Operating Procedures (SOPs), especially in critical environments like a cleanroom.

At MFY, our training program is comprehensive and continuous. New hires undergo intensive initial training on GMP principles, cleanroom gowning and behavior (as per ISO 14644), SOPs relevant to their role, and the importance of data integrity and accurate documentation. This is not a one-time event. We hold regular refresher courses and specialized training sessions whenever a process is updated or new equipment is introduced. For our cleanroom personnel, gowning qualification is a periodic requirement, ensuring they can consistently gown up without introducing contaminants.

This investment in people creates a culture where quality is a shared responsibility. It empowers employees to identify potential issues and raise concerns, knowing they will be addressed constructively through our CAPA system. I remember an instance when a packaging technician noticed a small tear in the outer packaging of a box of cleanroom caps. Instead of ignoring it, he quarantined the box and reported it immediately. An investigation found that the supplier had made a minor change to their carton design. While the caps themselves were not compromised, this proactive observation allowed us to correct the issue with the supplier before it became a larger problem. This is the result of a culture where every detail matters.

GMP compliance requires multi-layered strategiesTrue

The text emphasizes that compliance isn't a single action but an integrated system involving supplier qualification, quality control, training, and documentation.

Final inspection alone ensures GMP complianceFalse

The article clearly states that quality control must be integrated throughout production, not just done at final inspection.

Technical recommendations for maintaining high standards in tubing

Are you equipped with the technical knowledge to specify and maintain high-purity tubing? The difference between compliance and failure often lies in the technical details—material choice, surface treatment, and joining methods. Overlooking these can lead to systemic issues that are costly and difficult to fix.

Key technical recommendations include specifying low-sulfur 316L stainless steel, mandating electropolishing for a low Ra internal surface, utilizing orbital welding for connections, and implementing a rigorous passivation process to ensure a corrosion-resistant and inert product contact surface.

To truly achieve and maintain the highest standards, one must move beyond general specifications and delve into the technical nuances that define superior pharmaceutical-grade tubing. It's not enough to simply ask for "316L tubing." The conversation must include specific limits on chemical composition, quantifiable targets for internal surface roughness (Ra), and defined procedures for cleaning, passivation, and handling. As a Global Business Director, I frequently engage in technical discussions with our clients' engineering teams. The goal is to ensure that the product they specify is perfectly aligned with their application's demands. A system designed for high-purity water (WFI)4 has different considerations than one designed for a viscous biologic product. Making the right technical choices upfront is the most effective way to ensure long-term performance, cleanability, and compliance of the entire system. These recommendations form the technical bedrock of a reliable and safe pharmaceutical manufacturing process.

Specifying Material and Surface Finish: Beyond the Basics

The starting point for technical excellence is the material specification, which must go beyond simply stating "316L stainless steel." For optimal weldability and corrosion resistance in pharmaceutical applications, it is crucial to specify a controlled sulfur content, typically aiming for a range of 0.005% to 0.017%. Sulfur levels below this range can lead to inconsistent weld penetration, while higher levels can degrade corrosion resistance. This level of detail is critical for systems requiring extensive on-site orbital welding. At MFY, we work with our steel suppliers to source heats of steel that fall within this "sweet spot," ensuring predictable and high-quality welds for our clients.

The internal surface finish is arguably the most critical technical attribute of the tube itself. The standard measure for this is Surface Roughness, or Ra, expressed in micrometers (µm) or microinches (µin). A lower Ra value indicates a smoother surface. For most pharmaceutical applications, a maximum Ra of 0.5 µm (20 µin) is the baseline requirement, while for critical sterile and biologic applications, specifications as low as 0.25 µm (10 µin) Ra are common. This smooth surface is achieved through electropolishing. This electrochemical process removes a microscopic layer of the surface material, leveling peaks and valleys and creating a non-porous, highly cleanable finish that minimizes sites for microbial adhesion and product buildup.

When specifying tubing, it is essential to request certification for the Ra value. This means the supplier must provide a report from a profilometer measurement, confirming that the supplied tubing meets the specified finish. Simply claiming a tube is "electropolished" is not enough; it must be backed by quantitative data. This provides the end-user with the necessary documentation for their validation package and the assurance that the surface is suitable for its intended use. We provide these reports as a standard part of our documentation package for all electropolished tubing.

The Critical Role of Passivation and Electropolishing

While often discussed together, electropolishing and passivation are distinct processes that are both vital for preparing stainless steel for pharmaceutical service. As described, electropolishing is a finishing process that dramatically improves surface smoothness. However, it also provides a significant secondary benefit: it enhances the material's natural passive layer. The passive layer is a very thin, invisible film of chromium oxide that forms on the surface of stainless steel, giving it its characteristic corrosion resistance. Electropolishing removes free iron and other contaminants from the surface, creating a cleaner base for a more uniform and robust passive layer to form.

Passivation is a specific chemical treatment, typically using an acid like nitric or citric acid, with the primary goal of removing any free iron from the surface and accelerating the formation of the chromium oxide passive layer. Even after polishing and meticulous cleaning, microscopic particles of free iron from tooling or handling can remain on the surface. These particles can become initiation sites for rust and corrosion. A dedicated passivation step, performed in a controlled manner after all mechanical fabrication is complete, is the final chemical "cleaning" that ensures the surface is truly "passive" and inert.

For any pharmaceutical system, it is a technical requirement that all stainless steel components be passivated before being put into service. At MFY, our pharmaceutical-grade tubing undergoes a rigorous passivation process in our facility after electropolishing and before final cleanroom packaging. We provide certification of this process in our documentation. For systems assembled on-site, the entire system, including all welds and fittings, must typically be passivated as a whole after assembly is complete to ensure the integrity of the entire fluid path. Understanding this technical requirement is crucial for the engineering contractors we work with.

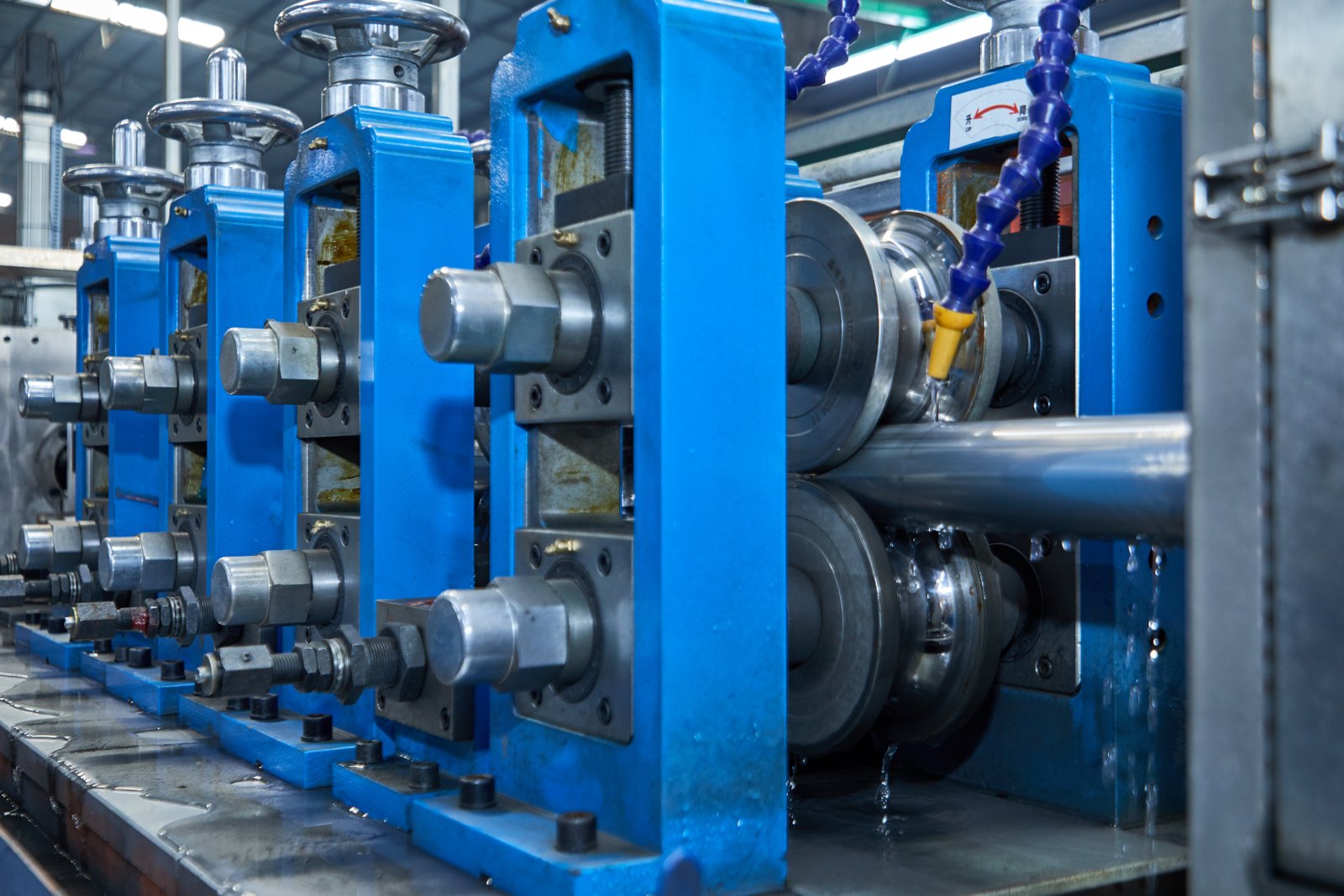

Orbital Welding and Connection Integrity

The method used to join sections of tubing is a critical control point. In high-purity pharmaceutical applications, traditional threaded or gasketed fittings are often avoided in process lines because they create crevices, dead legs, and potential leakage points that are difficult to clean and can harbor bacteria. The gold standard for permanent, sanitary connections is automated orbital welding. This process uses a specialized machine with a tungsten electrode that rotates (orbits) around the tube joint, creating a precise, repeatable, and smooth weld under a purged inert gas atmosphere (typically argon).

The key technical advantages of orbital welding are numerous. It produces a full-penetration weld that is exceptionally smooth on the interior, minimizing any disruption to the fluid path or the creation of ledges where contaminants could collect. The automated nature of the process removes the variability associated with manual welding, ensuring that every weld is of the same high quality, which is a key tenet of GMP. The process is also highly documentable; modern orbital welding machines can print out a detailed report for each weld, recording parameters like current, travel speed, and purge time. This creates an invaluable log for the system's validation package.

As a tubing supplier, we ensure our product is optimized for this process by controlling the sulfur content and maintaining tight dimensional tolerances on the tube's outer diameter and wall thickness. This consistency allows the orbital welding machine's clamps to hold the tube securely and ensures a perfect abutment of the ends for a high-integrity weld. We often provide technical data to our clients' welding technicians to help them develop the ideal weld parameters for our specific tubing, fostering a collaborative approach to achieving a perfectly sealed, sanitary system.

316L requires controlled sulfur contentTrue

Optimal weldability requires sulfur content between 0.005%-0.017% in 316L stainless steel.

Electropolishing removes macro layersFalse

Electropolishing removes microscopic surface layers to improve smoothness, not macroscopic layers.

Conclusion

Achieving compliance with ISO 14644 and GMP for pharmaceutical tubing is a non-negotiable commitment to quality. It demands a holistic approach, from stringent material control to meticulous process execution. Partnering with a technically proficient supplier is key to building a truly safe, reliable, and compliant manufacturing system.

-

Discover advantages of 316L stainless steel in pharmaceutical-grade tubing applications ↩

-

Understand supply chain complexities and risks in sourcing stainless steel for manufacturing ↩

-

Learn why on-site audits are essential for supplier qualification ↩

-

Understand different design requirements for high-purity water systems ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.