Electropolishing vs Mechanical Polishing for Sanitary Tubes

Are you struggling to decide on the right surface finish for your sanitary tubing? The choice between electropolishing and mechanical polishing can be confusing, yet it's a decision that critically impacts system hygiene, longevity, and operational costs, potentially risking product contamination and costly operational failures.

Electropolishing is an electrochemical process that removes a microscopic layer of the tube's surface, resulting in a passive, ultra-smooth, and contaminant-free finish. In contrast, mechanical polishing is an abrasive method that smears the surface to reduce roughness, which can embed impurities and create stress.

This decision goes far beyond simple aesthetics; it's a fundamental choice that affects the long-term safety and efficiency of your entire operation. The wrong finish can lead to biofilm buildup, corrosion, and cleaning challenges. In this article, I’ll guide you through the critical differences and help you understand which method is truly best for your application.

As the Global Business Director at MFY, I've seen countless clients grapple with issues stemming from incorrectly specified tube finishes. The debate isn't just academic—it has real-world consequences for industries like food, beverage, and pharmaceuticals, where sanitation is paramount. A surface that looks smooth to the naked eye can be a microscopic minefield of peaks and valleys where bacteria thrive. Understanding the science behind the shine is the first step toward building a truly resilient and safe sanitary system.

What are the fundamental differences between electropolishing and mechanical polishing?

Choosing a tube finish based on appearance alone is a common but risky oversimplification. This superficial understanding can lead to selecting a polishing method that compromises the integrity of your entire sanitary system. Let's delve into the core process differences to ensure your choice is based on science, not just shine.

The fundamental difference lies in their method of material removal. Electropolishing vs Mechanical Polishing is a non-contact, electrochemical process that dissolves the surface layer, preferentially leveling microscopic peaks. Mechanical polishing is a physical, abrasive process that grinds and smears the surface to achieve smoothness, often trapping contaminants.

These distinct mechanisms are what set the stage for all subsequent performance differences, from cleanability to corrosion resistance. A client of ours, a large dairy producer in Southeast Asia, was experiencing persistent issues with their Clean-in-Place (CIP) cycles. They were using mechanically polished tubes that, despite having a low surface roughness (Ra) value, were difficult to clean. Biofilm would accumulate, leading to longer cleaning times, increased chemical usage, and unacceptable microbial counts. The issue wasn't the cleaning protocol; it was the microscopic topography of the tube surface itself. The smeared and folded-over metal from mechanical polishing was creating safe harbors for bacteria. When they switched to our electropolished tubes for a new production line, their CIP validation was faster and their operational efficiency improved dramatically. This experience highlights why understanding the how behind the polish is so critical for any sanitary application. It’s not just about creating a smooth surface, but about creating a defensible sanitary surface.

The choice between these two methods ultimately shapes the metallurgical and topographical character of the steel, with profound implications for its performance in a sterile environment. It’s a classic case of the process defining the outcome. While both aim to reduce surface roughness, their approaches are diametrically opposed—one is a process of controlled dissolution, while the other is one of controlled abrasion. This foundational difference is where the conversation about true sanitary quality begins, and it's where we guide our clients to focus their attention to prevent costly long-term problems.

The Mechanism of Material Removal: Anodic Dissolution vs. Abrasive Smearing

At its core, electropolishing is a process of controlled, accelerated corrosion. The stainless steel tube is submerged in a specially formulated electrolyte bath (typically a blend of sulfuric and phosphoric acids) and serves as the anode (the positive electrode). When a DC current is applied, the metal surface begins to dissolve. The key is that the current density is naturally higher on the microscopic "peaks" of the surface than in the "valleys." This causes the peaks to dissolve at a much faster rate, resulting in a leveling effect that produces a truly smooth, featureless surface at a microscopic level. It’s a precise and non-contact method that removes material without applying any mechanical force.

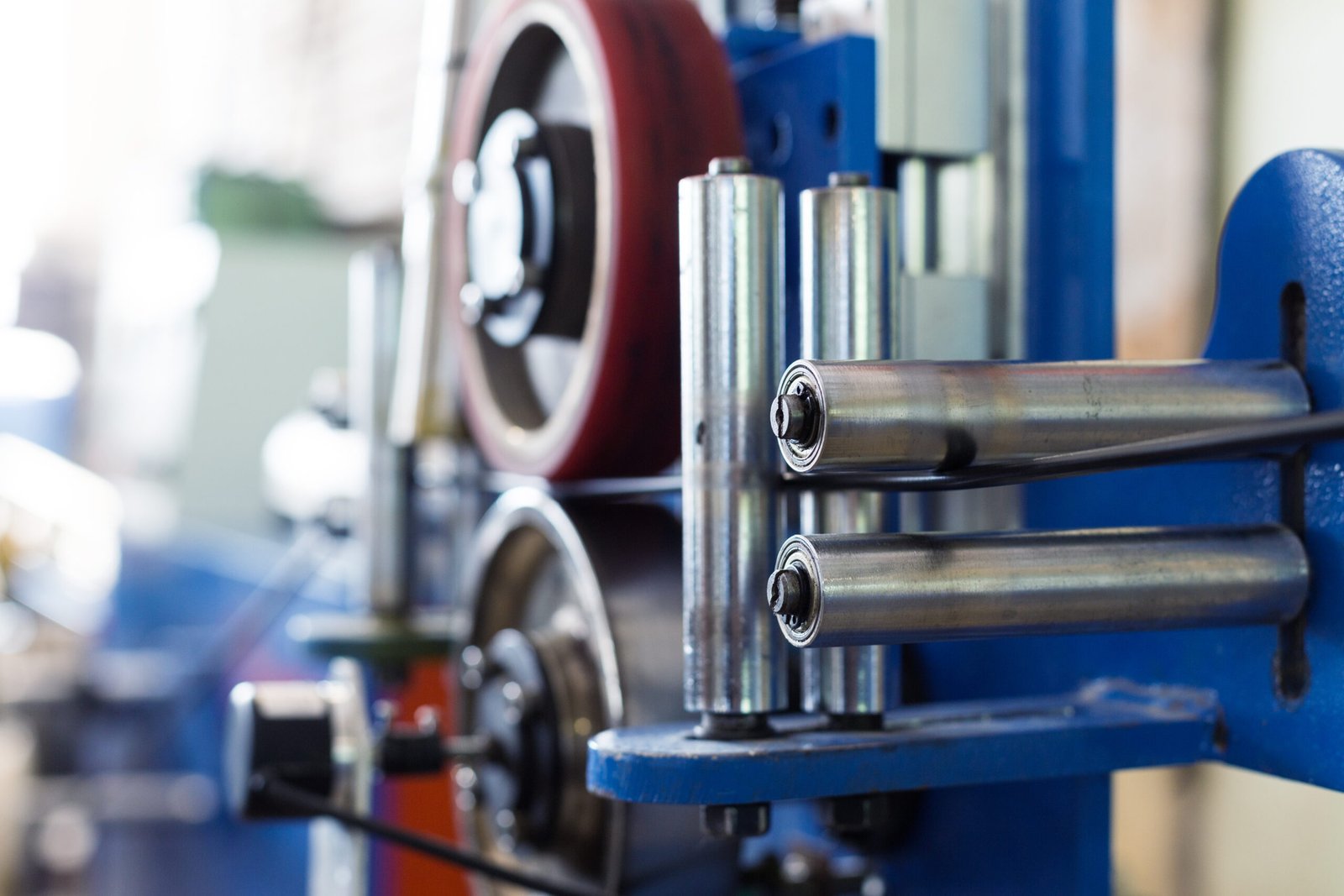

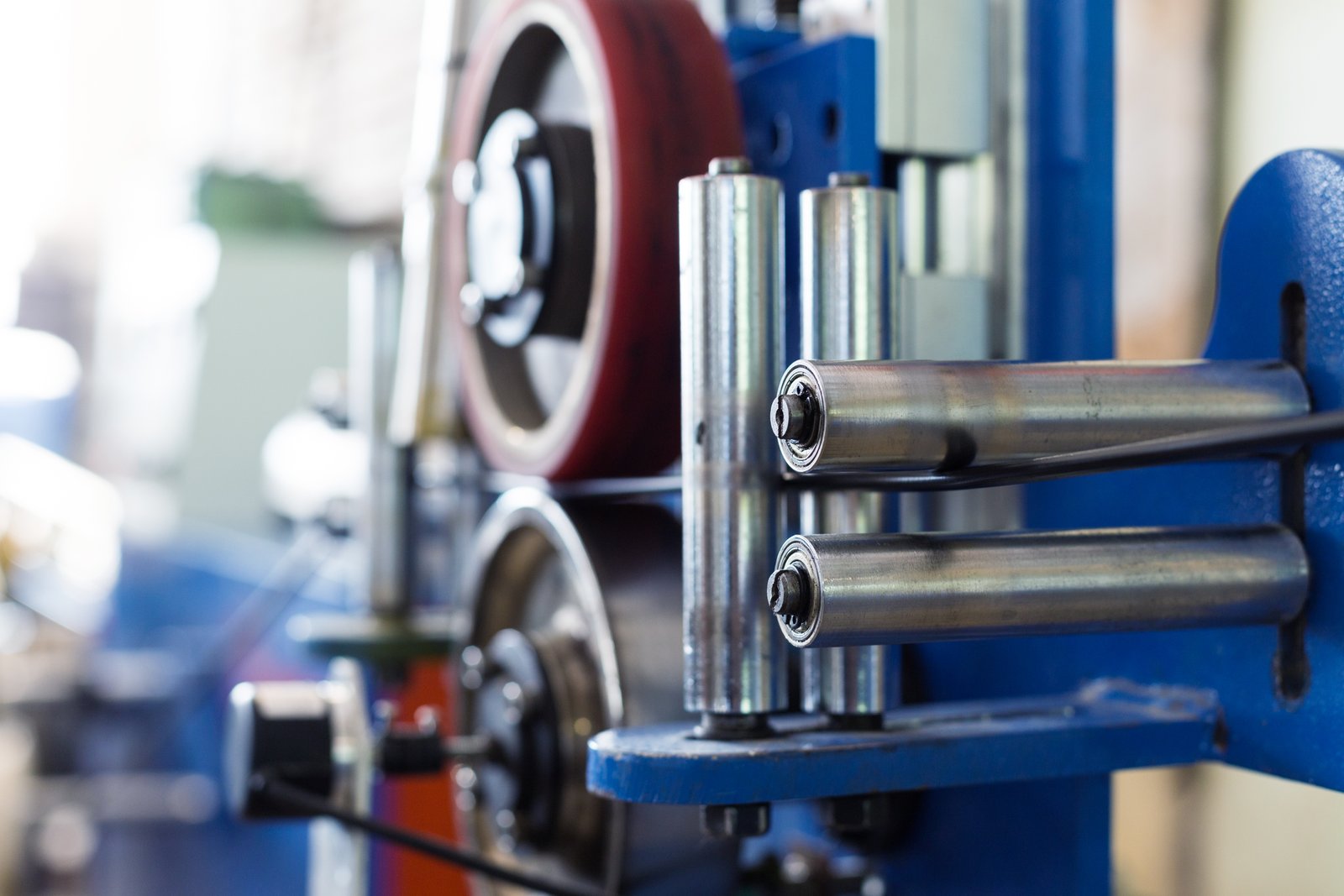

Mechanical polishing, conversely, is a purely physical process. It relies on friction and abrasion to alter the surface. This is typically done using progressively finer abrasive materials, delivered via belts, wheels, or slurries. Instead of cleanly removing the peaks, this process essentially pushes, smears, and folds the peak material into the valleys. While this action reduces the measured Ra value and creates a bright, reflective finish, it doesn't eliminate the underlying imperfections. It covers them up, creating a deceptively smooth surface that hides a chaotic, stressed, and potentially contaminated subsurface layer.

The most critical distinction is the final state of the surface. Surface Topography and Contaminant Entrapment1. Electropolishing removes the outer skin of metal that may have been altered or contaminated during tube manufacturing, exposing a pristine, undisturbed grain structure. It simultaneously passivates the surface by enriching it with chromium. Mechanical polishing, on the other hand, creates a heavily deformed surface layer, known as the Beilby layer, and can embed abrasive particles (like aluminum oxide or silicon carbide) and other foreign materials directly into the steel, which can later become corrosion initiation sites.

Impact on Surface Metallurgy and Stress

Every manufacturing process imparts some level of stress into the material, and surface finishing is no exception. The aggressive nature of mechanical polishing—the grinding and smearing—induces high levels of compressive stress into the surface layer of the steel. This stressed, deformed layer is metallurgically different from the base material. It is less stable and significantly more susceptible to chemical attack and stress-corrosion cracking. The energy imparted into the surface makes it more reactive and less able to resist corrosive environments.

Electropolishing is fundamentally a stress-free process. Because there is no mechanical contact, it does not induce any stress or strain into the material. In fact, it does the opposite. By removing the outer, often stressed, layer of metal left over from tube drawing, welding, or initial grinding, electropolishing effectively relieves stress from the component's surface. This results in a stabilized, metallurgically clean surface that is in its optimal state to resist corrosion. I recall a case with a pharmaceutical client in India whose Water for Injection (WFI) system was experiencing rouging, a form of iron oxide contamination. An investigation revealed that the mechanically polished tubes they had sourced elsewhere contained embedded iron particles from the polishing process. These particles were the nucleation sites for the corrosion. After they replaced the failed section with MFY's electropolished tubes, the rouging issue was completely resolved, saving them from potential batch contamination and regulatory scrutiny.

This difference in metallurgical impact is why many stringent industry standards, such as the ASME-BPE (Bioprocessing Equipment) standard, heavily favor electropolishing for critical product-contact surfaces. The goal is to create a surface that is not only smooth but also passive and inert. Electropolishing achieves this by its very nature, while mechanical polishing, despite its aesthetic appeal, introduces metallurgical characteristics that are fundamentally undesirable in a high-purity environment.

Resultant Surface Topography and Contaminant Entrapment

The final surface topography is perhaps the most critical differentiator for sanitary applications. On a microscopic scale, a mechanically polished surface is a landscape of folded-over peaks, scratches, and embedded particles. These features, while too small to see, are enormous relative to bacteria and other microbes. They create countless microscopic crevices, undercuts, and pockets where process fluids can stagnate and microorganisms can attach, colonize, and form biofilm. Once biofilm is established, it is notoriously difficult to remove with standard cleaning procedures, as the microorganisms are protected by the surface features and their own secreted polymeric matrix.

Electropolishing creates a completely different topography. It is a smooth, gently undulating, open, and featureless profile. There are no folds, no hidden crevices, and no embedded debris. This "macro-smooth" profile makes the surface exceptionally easy to clean and drain. There are no microscopic hiding places for bacteria to gain a foothold, significantly reducing the risk of biofilm formation. Cleaning fluids can access the entire surface effectively, and rinsing is more complete, leaving behind no residues.

To illustrate this, we've often used scanning electron microscope (SEM) images to show our clients the difference. The mechanically polished surface looks chaotic and damaged, while the electropolished surface is pristine and clean. This visual evidence is powerful. It shifts the conversation from a simple Ra number to a more sophisticated understanding of true sanitary design.

| Feature | Mechanical Polishing | Electropolishing |

|---|---|---|

| Process Type | Abrasive / Mechanical | Electrochemical / Non-contact |

| Material Removal | Smears & deforms surface peaks | Dissolves surface peaks |

| Surface Stress | High compressive stress induced | Stress-free; relieves existing stress |

| Surface Purity | Risk of embedded abrasives/iron | Atomically clean and pure |

| Ra Value | Can achieve low Ra values | Can achieve very low Ra values |

| Cleanability | Lower; risk of biofilm in crevices | Superior; smooth, open profile |

| Corrosion Resistance | Reduced; damaged passive layer | Enhanced; thick, chromium-rich layer |

Electropolishing removes surface peaksTrue

Electropolishing dissolves microscopic peaks through electrochemical action, creating a smoother surface than mechanical polishing.

Mechanical polishing enhances corrosion resistanceFalse

Mechanical polishing actually reduces corrosion resistance by damaging the passive layer and embedding contaminants that can initiate corrosion.

How do electropolishing and mechanical polishing impact the surface quality of sanitary tubes?

A shiny tube might look clean, but is it truly sanitary? This is a question we constantly encourage our clients to ask. Hidden microscopic flaws can harbor dangerous bacteria, compromise product purity, and lead to catastrophic batch failures. Let's examine how each polishing method defines "surface quality."

Electropolishing vastly improves sanitary quality by creating a microscopically smooth, passive, and ultra-clean surface that enhances cleanability and corrosion resistance. Conversely, mechanical polishing, while achieving a low Ra value, can degrade true sanitary quality by introducing stress, embedding contaminants, and creating microscopic surface defects.

For our clients in the food, beverage, and biotech industries, this isn't an academic debate; it's a matter of brand reputation, consumer safety, and operational viability. A single contamination event can trigger costly recalls, damage consumer trust, and lead to significant financial losses. I once worked with a promising startup in the craft beverage sector. They invested heavily in their brewing equipment but opted for mechanically polished tubing to save on initial costs. Within six months, they were battling persistent wild yeast contaminations that were traced back to biofilm buildup inside the tubes. The difficult-to-clean surfaces were ruining their product. This hard lesson underscores that true surface quality is an investment, not an expense, and it's defined by performance, not just appearance.

The concept of "quality" must be viewed through the lens of the application. In a sanitary context, quality is defined by four key metrics: cleanability, sterilizability, corrosion resistance, and the absence of surface anomalies that can harbor contaminants. A simple visual inspection or a single roughness measurement cannot capture this complete picture. The impact of the polishing method on the steel's metallurgy and microscopic topography is where the true quality lies. This deeper understanding allows companies to move from a reactive "clean-up" approach to a proactive "prevention" strategy, which is the cornerstone of modern hygienic design and a principle we champion at MFY. It's about building systems that are inherently safe and efficient from the inside out.

Cleanability and Sterilizability: The True Test of a Sanitary Surface

The ultimate measure of a sanitary surface is its ability to be reliably and efficiently cleaned and sterilized. This is where Clean-in-Place (CIP)2 and Sterilize-in-Place (SIP) protocols come into play. The effectiveness of these protocols is directly tied to the microscopic topography of the tube's inner surface. An electropolished surface presents a significant advantage here. Its smooth, open, and crevice-free profile allows cleaning agents, detergents, and sterilizing media to flow across the entire surface without obstruction. This ensures complete contact and effective removal of any residues or microorganisms. Consequently, CIP cycles can often be run for shorter durations, at lower temperatures, or with less aggressive chemical concentrations, leading to tangible savings in energy, water, chemicals, and time.

In stark contrast, the surface of a mechanically polished tube is a minefield for CIP/SIP processes. The microscopic scratches, folds, and embedded particles act as anchors for product residue and bacteria. During a cleaning cycle, these features can shield microorganisms from the flow of cleaning agents, allowing them to survive and proliferate, eventually forming a resilient biofilm. Overcoming this requires more aggressive cleaning protocols—higher temperatures, longer contact times, and stronger chemicals—which not only increases operating costs but also accelerates the wear and tear on the entire system, including gaskets and other components.

Industry data supports this conclusion. Studies conducted by organizations like the European Hygienic Engineering & Design Group (EHEDG)3 have repeatedly shown that biofilm attachment and formation are significantly more rapid and tenacious on mechanically polished surfaces compared to electropolished ones under identical conditions. In some studies, the rate of biofilm formation has been observed to be three to four times faster on mechanically finished surfaces. This is a critical data point for any manufacturer in a regulated industry, as it directly impacts process validation and risk management.

Corrosion Resistance and the Role of the Passive Layer

The inherent "stainless" quality of stainless steel is not due to the bulk material itself, but to a very thin, invisible, and tenacious surface layer of chromium oxide. This is known as the passive layer. A high-quality sanitary tube must have a robust and uniform passive layer. Electropolishing4 is unique in its ability to enhance this crucial feature. The electrochemical process selectively removes iron atoms from the surface at a slightly higher rate than chromium atoms. This action significantly enriches the surface with chromium, effectively increasing the chromium-to-iron ratio from a typical 1:2 in the base metal to as high as 2:1 or even greater on the finished surface. This chromium-rich surface reacts with oxygen to form a thicker, more uniform, and more chemically resistant passive layer than what would form naturally.

Mechanical polishing has the opposite effect. The abrasive action can damage, thin, or even completely remove the naturally occurring passive layer. Worse still, it can contaminate the surface with free iron, either from the abrasive media itself or from contact with other carbon steel tooling. This embedded iron disrupts the formation of a continuous chromium oxide layer and creates active sites for corrosion to begin, particularly pitting and crevice corrosion, which are common failure modes in sanitary systems exposed to chlorides (found in many foods, water sources, and cleaning agents).

We worked with a client in the Middle East who operates a large-scale desalination plant. They were using mechanically polished 316L stainless steel tubes for some non-critical process lines, but the high-chloride environment was causing premature failure due to severe pitting corrosion. The initial cost savings were quickly erased by maintenance costs and downtime. For their next expansion phase, we supplied them with MFY's electropolished tubes. The enhanced passive layer created by electropolishing provided far superior resistance to the chloride-induced pitting, dramatically extending the service life of the system and validating the total cost of ownership approach.

Surface Roughness (Ra) vs. True Surface Profile

One of the most persistent misconceptions in the industry is the over-reliance on the average surface roughness (Ra) value as the sole indicator of surface quality. While Ra is a useful and easy-to-measure parameter, it does not tell the whole story. Ra is a one-dimensional measurement of the average height of the peaks and valleys on a surface. It cannot distinguish between different surface shapes or topographies. A mechanically polished surface and an electropolished surface can have the exact same Ra value, but their microscopic profiles and, therefore, their sanitary performance, will be worlds apart.

Imagine a profilometer stylus tracing across two surfaces, both with an Ra of 0.4 µm. The mechanically polished surface would be characterized by sharp, jagged peaks and valleys, with folded-over material and hidden crevices. The electropolished surface, in contrast, would be a series of smooth, open, rolling hills. While the average height is the same, the morphology is completely different. The jagged profile is difficult to clean and prone to contamination, while the smooth, open profile is ideal for sanitary applications.

This is why we always stress the importance of specifying the finishing method, not just the final Ra value. For critical applications, specifying "electropolished to Ra < 0.5 µm" is far more meaningful and protective than simply asking for "Ra < 0.5 µm." This ensures you are getting the superior surface morphology, enhanced passive layer, and metallurgical purity that only electropolishing can provide.

| Parameter | Mechanically Polished (Ra 0.4µm) | Electropolished (Ra 0.4µm) |

|---|---|---|

| Surface Profile | Jagged peaks, sharp valleys, folds | Smooth, rounded, open contours |

| Biofilm Risk | High; numerous attachment sites | Low; minimal attachment sites |

| Passive Layer | Thin, damaged, non-uniform | Thick, robust, chromium-enriched |

| Chromium/Iron Ratio | ~0.5 : 1 (low) | >1.5 : 1 (high) |

| CIP Efficiency | Lower; requires more aggressive cycles | Higher; efficient cleaning |

| Contamination Risk | High (embedded abrasives, bacteria) | Extremely Low (ultra-pure surface) |

Electropolishing enhances corrosion resistanceTrue

Electropolishing enriches surface chromium content, creating a thicker passive layer that resists corrosion better than mechanical polishing.

Ra value alone determines cleanabilityFalse

Identical Ra values can have completely different surface morphologies - electropolished surfaces clean better despite matching mechanical polish Ra measurements.

What advantages does electropolishing offer over mechanical polishing for sanitary applications?

When considering the rigorous demands of sanitary systems, the benefits of one method often far outweigh the other. You may be facing pressure to reduce initial costs, but this can lead to overlooking long-term operational integrity. The key is to see the advantages in terms of total system performance.

For sanitary applications, electropolishing advantages include superior cleanability, corrosion resistance, and surface purity. It creates a truly passive, non-contaminating surface that extends system life, improves product safety, and reduces long-term operational costs compared to mechanical polishing.

These advantages are not theoretical; they translate into direct operational benefits. Consider a biopharmaceutical client producing high-value biologics. For them, the absolute prevention of contamination and metallic ion leaching is non-negotiable. The product's value is immense, and the risk of batch loss is a multi-million dollar threat. The superior, inert surface created by electropolishing provides the highest level of assurance against such events. It's not just a better polish; it's a critical component of their risk management strategy. By choosing electropolishing, they are investing in the predictability and safety of their manufacturing process, an advantage that far exceeds the initial cost difference.

The selection of a surface finish is a critical control point in hygienic design. The advantages of electropolishing are multifaceted, touching on nearly every aspect of sanitary system performance, from the physical interaction with process fluids to the metallurgical stability of the material itself. It is a proactive step toward building a system that is not only compliant with standards like ASME-BPE standards5 but is also inherently more robust, reliable, and economical to operate over its entire lifecycle. As we explore the specific benefits, it becomes clear why electropolishing is the default standard for industries where purity and safety cannot be compromised. The peace of mind that comes from knowing your system's surfaces are optimized for hygiene is, for many of our clients, the greatest advantage of all.

Advantage 1: Superior Cleanability and Reduced Biofilm Formation

The primary advantage of electropolishing in any sanitary application is the unparalleled level of cleanability it provides. As discussed, the microscopic smoothness and lack of surface defects mean there are virtually no sites for bacteria or product residue to adhere to. This has a profound impact on daily operations. Cleaning cycles (CIP) become faster, more effective, and more reliable. This translates directly into increased production uptime, as less time is spent on cleaning and more time is available for manufacturing.

Furthermore, the reduced risk of biofilm formation is a massive advantage. Biofilms are notoriously resistant to cleaning agents and can lead to persistent contamination issues, product spoilage, and even health risks. By creating a surface that is inhospitable to biofilm attachment, electropolishing fundamentally reduces the operational risk profile of the plant. A major infant formula manufacturer we work with in Southeast Asia considers this advantage paramount. For them, the risk of Cronobacter contamination is a constant concern. The electropolished surfaces within their processing lines are a key part of their multi-barrier approach to preventing such contamination, ensuring the safety of their vulnerable end-users.

The operational savings are also significant. A more easily cleaned surface requires less hot water, fewer chemicals, and less time. Over the course of a year, these savings in utilities and labor can be substantial, contributing to a lower total cost of ownership. The ability to validate cleaning protocols more easily and with greater confidence also reduces the burden on quality assurance teams and simplifies regulatory compliance.

Advantage 2: Enhanced Corrosion Resistance and Material Purity

The second major advantage is the significant improvement in corrosion resistance. By removing surface contaminants (like free iron) and creating a thicker, chromium-enriched passive layer, electropolishing makes the stainless steel far more resilient to attack from corrosive agents found in products and cleaning chemicals. This is especially critical in environments with high levels of chlorides, acids, or sanitizers like sodium hypochlorite. The enhanced passive layer prevents micro-corrosion that could otherwise lead to pitting, rouging, or metallic ion leaching into the product.

This material purity is of utmost importance in the pharmaceutical and semiconductor industries. In pharmaceutical manufacturing, any leaching of metallic ions (like iron, nickel, or chromium) from the tubing can contaminate the drug product, potentially affecting its stability, efficacy, or even patient safety. Electropolishing creates the most inert and non-reactive stainless steel surface possible, making it the ideal choice for high-purity water systems (WFI), bioreactors, and final product distribution lines.

At MFY, we often provide material test reports and surface analysis data to our clients in these critical sectors. We can demonstrate, for example, the post-electropolishing chromium-to-iron ratio on the surface. This data provides documented proof of the enhanced corrosion resistance and purity, giving engineers and quality managers the confidence that the material will perform as required and protect the integrity of their high-value products. This advantage extends the service life of the equipment, reducing the need for costly replacements and unplanned downtime.

Advantage 3: Optimal Surface for Sterility and Deburring

Beyond cleanliness and corrosion, electropolishing offers unique advantages for processes requiring absolute sterility and for components with complex geometries. The process is excellent at deburring, as the higher current density at sharp edges and corners causes them to dissolve faster. This means that any microscopic burrs left over from cutting or welding can be effectively removed without a secondary mechanical process. These burrs are notorious for breaking off and causing particulate contamination, as well as being difficult-to-clean sites for bacterial harborage. Electropolishing smooths these features, creating a safer overall component.

For sterilization, whether through steam (SIP) or other methods, the electropolished surface is ideal. Its supreme smoothness ensures that no air pockets or residues shield microorganisms from the sterilizing agent, leading to a more reliable and effective sterilization cycle. In applications like surgical equipment or bioprocessing fermenters, where achieving and maintaining sterility is a life-or-death matter, electropolishing is not just an advantage—it is a necessity.

ly, there is an aesthetic and inspection advantage. The bright, highly reflective, mirror-like finish of an electropolished surface is not just for show. It makes visual inspection of the surface for cleanliness or defects much easier. Any remaining soil or residue stands out clearly against the brilliant background, simplifying inspection procedures and providing a higher level of quality assurance. This combination of deburring, enhanced sterilizability, and inspectability makes electropolishing a comprehensive solution for creating the highest quality sanitary components.

Electropolishing improves corrosion resistanceTrue

Electropolishing creates a thicker chromium-enriched passive layer that significantly enhances stainless steel's resistance to corrosive agents.

Mechanical polishing removes more materialFalse

Electropolishing actually removes more microscopic peaks and imperfections while preserving more base material compared to mechanical polishing.

In what scenarios might mechanical polishing be more appropriate than electropolishing?

While I am a strong advocate for electropolishing in critical applications, it's essential to maintain a balanced perspective. The best engineering solution is always one that fits the specific context of the application. There are indeed scenarios where mechanical polishing is not only adequate but may also be the more appropriate and practical choice.

Mechanical polishing is often more appropriate for applications where the hygienic requirements are less stringent, initial project cost is the primary driver, or when a specific non-reflective aesthetic finish, such as a brushed or satin look, is desired for non-product-contact surfaces.

The key is a thorough risk assessment. We guide our clients to ask: What is this tube's function? Does it come into direct contact with the final product? What are the consequences of a contamination event in this specific line? For example, tubing used for plant utilities like compressed air (that isn't used for product transfer) or for glycol in a cooling jacket6 doesn't require the supreme purity of an electropolished surface. In these cases, a durable and cost-effective mechanically polished tube is a perfectly sound engineering and business decision. Recognizing these distinctions is the mark of an efficient and well-planned project.

Making a blanket statement that one method is always superior is an oversimplification that can lead to over-engineering and unnecessary expense. At MFY, our goal is not just to sell the highest-spec product, but to provide the right product for our clients' needs. A distributor or trader, for instance, needs to stock a range of products to serve diverse customer requirements. Understanding where mechanical polishing fits into this spectrum is crucial for them to effectively serve their market. By analyzing the application's demands—considering cost, aesthetics, and function—we can collaboratively determine the most sensible path forward, ensuring that resources are allocated where they matter most for safety and performance. This pragmatic approach ensures both operational integrity and fiscal responsibility.

Applications with Lower Hygienic Requirements

The most common and appropriate use for mechanical polishing is in applications that are not in the direct "hygienic zone." This includes a wide range of uses within a processing facility. For instance, structural components made from stainless steel tubing, such as equipment frames, support structures, and catwalk railings, do not need the microscopic purity of electropolishing. Here, a standard mechanically polished or brushed finish provides a clean, aesthetic look and adequate corrosion resistance for the ambient plant environment at a much lower cost.

Similarly, many utility lines fall into this category. Piping for jacketed heating or cooling media (like steam, water, or glycol), plant air, or certain drainage systems that do not handle product waste are excellent candidates for mechanically polished tubes. In these cases, the risk of product contamination is negligible or non-existent. The primary requirements are structural integrity and basic corrosion resistance, both of which are adequately met by standard mechanical finishes. A construction contractor building a new food processing plant will specify electropolished tubes for product lines but will value the cost savings of using mechanically polished tubes for these extensive utility networks.

It is a matter of matching the specification to the risk. Over-specifying electropolishing for these non-critical areas adds significant cost without a corresponding increase in safety or performance. A well-designed system intelligently allocates the budget, investing in high-purity finishes where they are essential to protect the product and opting for more economical solutions where they are not.

Cost-Sensitive Projects and Initial Investment

There's no denying that upfront cost is a major factor in any project. Mechanical polishing is, as a process, significantly less expensive than electropolishing. Electropolishing requires a complex chemical setup, DC rectifiers, significant energy consumption, and stringent environmental controls for waste electrolyte. Mechanical polishing, while labor-intensive, requires less capital-intensive equipment. For projects with extremely tight initial budgets, this cost difference can be the deciding factor.

A start-up company or a business in a highly price-competitive market segment might choose mechanical polishing for their initial setup to minimize capital expenditure. For example, a small-scale producer of jams or sauces, where the product is less sensitive than a pharmaceutical biologic, might decide that a well-maintained system with mechanically polished tubes presents an acceptable level of risk for their business model. They may plan to invest in more frequent or rigorous cleaning protocols to offset the less-ideal surface finish.

However, I always caution my clients to think in terms of Total Cost of Ownership (TCO). While the initial purchase price of mechanically polished tubes is lower, the lifetime costs can be higher due to increased spending on cleaning chemicals, water, energy, and labor. There's also the less tangible, but very real, cost associated with a higher risk of product loss or downtime. For some, the lower upfront cost is a necessary trade-off, but it's a decision that should be made with a full understanding of these potential long-term financial implications.

When Specific Aesthetic Finishes are Desired

Aesthetics can be a valid reason for choosing mechanical polishing, particularly for components that are visible to operators or the public. Electropolishing produces a very specific, highly reflective, chrome-like finish. While this is desirable for inspection, it may not align with the desired look for certain architectural or equipment applications.

Mechanical polishing can produce a wide variety of finishes. A "brushed" finish (also known as a #4 or satin finish) is very common for architectural elements, equipment enclosures, and appliance surfaces. This finish has a uniform, directional grain that is good at hiding fingerprints and minor scratches, making it a practical and aesthetically pleasing choice for non-sanitary surfaces. Another option is a non-directional "satin" finish, which provides a soft, low-reflectivity look.

Consider a company building a high-end commercial kitchen or a visible brewing area in a brewpub. They want the durability and cleanliness of stainless steel, but they want a specific aesthetic that matches their brand. For the external, non-product contact surfaces of tanks, control panels, and wall cladding, a brushed mechanical finish is often the preferred choice. It delivers the desired look while still providing good general-purpose corrosion resistance and cleanability suitable for that environment. In these cases, the choice is driven by design intent rather than sanitary performance.

| Scenario | Recommended Choice | Rationale |

|---|---|---|

| Critical Product Contact | Electropolishing | Maximizes cleanability, purity, and corrosion resistance; minimizes risk. |

| Non-Product Utility Lines | Mechanical Polishing | Lower cost, adequate performance for non-critical media (e.g., glycol, plant air). |

| Structural Components | Mechanical Polishing | Cost-effective for frames and supports where hygiene is not a factor. |

| Extreme Budget Constraint | Mechanical Polishing | Lowest initial investment, but requires careful consideration of long-term costs. |

| Specific Aesthetic Finish | Mechanical Polishing | Can achieve specific looks like "brushed" or "satin" for architectural/visible parts. |

Mechanical polishing is cheaper initiallyTrue

Mechanical polishing requires less complex equipment and lower capital investment compared to electropolishing, making it more cost-effective for initial projects.

Electropolishing is always superiorFalse

Electropolishing is not always the best choice; mechanical polishing is more appropriate for non-hygienic applications, cost-sensitive projects, or specific aesthetic finishes.

What are the recommended practices for choosing the right polishing method for sanitary tubes?

Making the right choice is a strategic decision that balances risk, cost, and performance. To navigate this effectively, a clear and systematic approach is essential. It's about moving beyond assumptions and implementing a process that ensures the final selection truly aligns with your operational and quality goals.

The best practice is to base your decision on a risk assessment of specific applications, evaluating the total cost of ownership rather than just the initial price, and clearly defining and verifying the final surface specification with your supplier, including the method and acceptance criteria.

This structured approach transforms the decision from a simple line item on a purchase order to an integral part of your quality management system. I've worked with many engineering contractors7 who have adopted this methodology. By creating a simple "Hygienic Criticality Matrix" for each project, they categorize every single pipeline—as high, medium, or low risk—and assign a pre-defined surface specification to each. This not only ensures consistency and safety but also streamlines their procurement process and provides clear documentation for regulatory audits. It’s a practice that pays dividends in both safety and efficiency.

Ultimately, the responsibility for choosing the correct finish rests with the end-user or the system designer. As a supplier, our role at MFY is to be a technical partner in this process. We provide the necessary information, data, and expertise to empower our clients to make informed decisions. An educated customer is our best customer, because they understand the value that is engineered into a high-quality, properly finished tube. By adopting the following practices, you can build a framework for making the optimal choice every time, safeguarding your product, your process, and your brand. This isn't just about buying steel tubes; it's about building a foundation for long-term success.

Define Your Application's Criticality

The first and most important step is to analyze the specific role of the tubing within your system. Not all pipes are created equal. You should categorize each line based on its level of risk and hygienic requirement. A simple way to do this is to classify them as: Product-Contact, In-Process but Non-Product-Contact, or Utility. Product-contact surfaces are those that the final, sellable product will touch. These are the most critical and almost always demand the highest quality finish, making electropolishing the default choice. This includes lines leading to fillers, holding tanks, and any post-pasteurization or final purification steps.

In-process lines might handle intermediate products, buffers, or raw materials. Here, a risk assessment is needed. For a high-purity pharmaceutical buffer, electropolishing is still the wise choice. For a raw dairy intake line pre-pasteurization, a high-quality mechanical polish might be deemed acceptable, though electropolishing would still offer superior cleaning benefits. Utility lines, as previously discussed, are typically the least critical. For example, a leading engineering contractor we supply for food & beverage projects in India uses a clear rule: any surface after the final kill step (pasteurizer) must be electropolished. Everything before that point is evaluated on a case-by-case basis, and utilities are standard mechanical polish. This clear delineation removes ambiguity and ensures investment is focused on the most critical areas.

This process of definition and classification should be a formal part of your project planning. It should be documented and agreed upon by the engineering, quality, and production teams to ensure everyone is aligned on the requirements and the rationale behind them.

Evaluate Total Cost of Ownership (TCO), Not Just Upfront Price

The appeal of a lower initial price for mechanically polished tubes is strong, but it can be a misleading metric. A truly sound financial decision is based on the Total Cost of Ownership (TCO), which encompasses the entire lifecycle of the component. The TCO calculation should include the initial purchase price plus all associated operational and maintenance costs over the expected service life of the tubing. For sanitary tubing, this must include the cost of CIP cycles (water, energy, chemicals, time/downtime), the cost of routine maintenance and inspection, and, crucially, the cost of risk.

The "cost of risk" is the potential financial impact of a contamination event. This can include the value of a lost batch of product, the cost of a product recall, downtime for system investigation and re-sanitization, and the potential damage to your brand's reputation. When you factor these elements in, the slightly higher initial cost of electropolishing often reveals itself to be the more economical choice in the long run. The operational savings from more efficient cleaning and the massive cost avoidance from a lower risk of contamination can provide a return on the initial investment in a surprisingly short time.

We encourage our clients to perform this TCO analysis. A beverage manufacturer might find that reducing their CIP cycle time by just 15 minutes per day across multiple lines by using electropolished tubes translates into thousands of dollars in annual savings and dozens of extra hours of production. When framed this way, the decision becomes a clear business case for long-term efficiency and profitability.

Specify and Verify the Surface

Once you have decided on the appropriate method, it is critical to specify it clearly and have a process for verifying what you receive. A vague specification like "sanitary finish8" is open to interpretation and can lead to problems. A proper specification should be unambiguous. For a critical application, it should read something like: "316L Stainless Steel Sanitary Tube, electropolished and passivated on the ID surface to an average roughness of Ra < 0.4 µm." This leaves no room for doubt. It defines the material, the process, the location (ID), and the acceptance criterion.

Verification is the final step. For the most critical applications, this may involve requesting documentation from your supplier, such as material test certificates (MTCs) to confirm the alloy and profilometer readings to prove the Ra value. At MFY, we provide this level of documentation as a standard part of our quality assurance for clients in regulated industries. For less critical applications, a visual inspection for consistency and quality of the finish may suffice. Some clients even perform their own spot checks with a portable surface roughness tester upon receiving a shipment.

Building a relationship with a trusted supplier who understands these requirements and has robust quality control systems is essential. A good supplier is a partner who can provide guidance, stand behind their product, and deliver the certified quality you need to operate safely and efficiently. This practice of "specify and verify" closes the loop, ensuring that the careful decision you made during the design phase is actually implemented in your facility.

Electropolishing reduces CIP cycle timeTrue

Electropolished surfaces have lower roughness, leading to more efficient cleaning and shorter CIP cycles.

Mechanical polish always costs lessFalse

While mechanically polished tubes have lower initial costs, electropolishing often has lower total cost of ownership when factoring in cleaning efficiency and contamination risks.

Conclusion

The choice between electropolishing and mechanical polishing is fundamental to sanitary system design. For critical applications, electropolishing's ability to deliver a microscopically smooth, passive, and ultra-clean surface makes it the superior choice for ensuring safety, enhancing cleanability, and maximizing the long-term reliability of your operations.

-

Discover why smooth topography is crucial for cleanliness in sanitary applications. ↩

-

Learn the importance of effective cleaning protocols in maintaining product safety and quality ↩

-

Understand the role of EHEDG in promoting hygienic practices and standards in industries ↩

-

Discover how electropolishing enhances corrosion resistance and cleanliness of stainless steel ↩

-

Understand how electropolishing helps meet ASME-BPE standards for hygienic design. ↩

-

Understand glycol's role in cooling systems to enhance efficiency and thermal management ↩

-

Discover methodologies adopted by engineering contractors for successful sanitary tube procurement ↩

-

Understand sanitary finish specifications for stainless steel tubing in critical applications ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.