Top Mistakes to Avoid When Sourcing Pipes Internationally

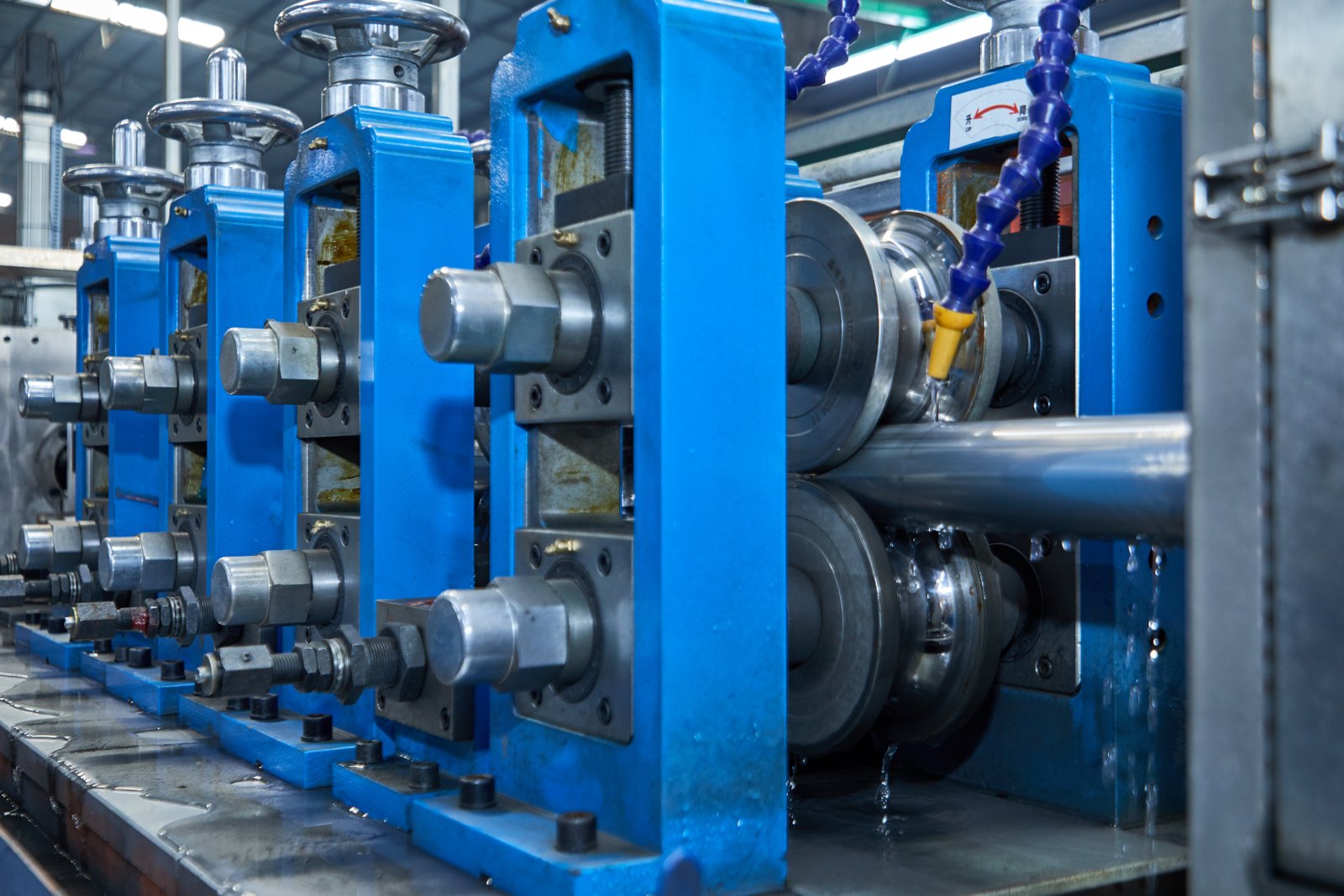

Sourcing pipes internationally can feel like navigating a minefield, fraught with potential for costly errors, from receiving substandard materials to facing unexpected project-halting delays. These mistakes can quickly derail your projects, inflate your budgets, and even tarnish your company's hard-earned reputation. However, by understanding these common pitfalls, you can approach the global market with confidence, secure the best value, and ensure your projects run smoothly.

Sourcing pipes internationally often involves mistakes like inadequate supplier vetting, unclear product specifications, neglecting quality control, overlooking complex logistics and compliance requirements, and ignoring cultural differences in business dealings. These errors can lead to significant financial and operational setbacks for businesses.

Venturing into international procurement without a clear roadmap can be daunting, but the rewards of a well-executed strategy are immense. The global marketplace offers incredible opportunities for quality, innovation, and cost-effectiveness if approached correctly. This article will guide you through the most common mistakes I've seen businesses make in my years at MFY, and more importantly, how you can avoid them to build a resilient and efficient supply chain.

As Global Business Director at MFY, a company deeply integrated into China's stainless steel industry, I've witnessed firsthand the complexities and aChartered Institute of Procurement & Supply (CIPS) studies1 about supply chain disruptions caused by international sourcing errors, and the impact on profitability and operational continuity. It’s not just about finding a supplier; it’s about finding the right partner who aligns with your quality standards, timelines, and business ethics. This comprehensive understanding is what we aim to foster.

What are the common mistakes made when sourcing pipes internationally?

Identifying the exact blunders in international pipe sourcing can feel overwhelming, especially when you're juggling multiple project demands and cost pressures. Ignoring these specifics, however, often leads to repeated, costly errors that directly impact your bottom line, project timelines, and overall operational efficiency. Let's pinpoint these common mistakes so you can proactively safeguard your procurement strategy and make informed decisions.

Common mistakes in international pipe sourcing include insufficient supplier due diligence, providing ambiguous or incomplete specifications, neglecting robust quality control measures, underestimating shipping complexities and customs regulations, and failing to account for all hidden costs beyond the initial price quote.

These mistakes aren't isolated incidents; they often stem from a combination of factors inherent in global trade. The sheer distance involved can make direct oversight challenging. Language barriers, while seemingly surmountable with translation tools, can lead to nuanced misunderstandings in technical specifications or contractual terms. Different business cultures approach negotiations, commitments, and problem-solving in varied ways, which, if unacknowledged, can lead to friction and unmet expectations. Furthermore, the pressure to secure the lowest possible unit price can sometimes overshadow the critical need for thoroughness in other areas, like verifying supplier credentials or investing in independent inspections.

At MFY, we've structured our processes to counteract these common pitfalls for our clients. For instance, I recall a client, a mid-sized engineering and construction contractor in Southeast Asia, who approached us after nearly facing a major setback. They had sourced pipes from a new, unvetted supplier based purely on an attractive price. The material certifications provided were questionable, and upon independent testing (which they thankfully decided to do last-minute), the pipe grade was incorrect, rendering it unsuitable for their high-pressure application. This could have led to catastrophic failures and significant liability. This experience underscores why a systematic approach to international pipe sourcing error prevention2, which addresses these potential mistakes head-on, is not just advisable but essential for success. We helped them secure the correct materials swiftly through our verified network, but the initial scare served as a valuable lesson. The journey of international sourcing requires vigilance and a clear understanding of where things can go wrong.

The challenge of international pipe sourcing is multifaceted, with potential pitfalls at nearly every stage, from initial supplier identification to final delivery and beyond. These aren't just minor inconveniences; they can escalate into significant financial burdens, operational gridlock, and even legal complications. Recognizing these common mistakes is the crucial first step toward building a more robust and reliable international procurement strategy for critical components like stainless steel pipes. It's about shifting from a reactive stance, where you're constantly firefighting problems, to a proactive one, where potential issues are anticipated and mitigated. As we delve deeper, we'll explore specific categories of these mistakes, providing insights into why they occur and, more importantly, how to construct safeguards against them, drawing from real-world scenarios and MFY's extensive experience in the global stainless steel market. This understanding will empower you to ask the right questions, demand the right assurances, and ultimately, forge stronger, more dependable supply chains.

Underestimating Supplier Vetting and Due Diligence

One of the most frequent and damaging mistakes is the failure to conduct thorough supplier vetting and due diligence. In the rush to secure a seemingly good deal or meet tight deadlines, some businesses might rely on superficial checks, such as a professional-looking website or initial claims of certifications. However, this superficial approach can expose a company to significant risks, including fraudulent suppliers who disappear after receiving payment, manufacturers producing consistently substandard quality, or partners who lack the financial stability or production capacity to fulfill large or ongoing orders reliably. The consequences can range from lost deposits and unusable goods to severe project delays and reputational harm. At MFY, our integrated supply chain model means we have deep insights into our production capabilities, but when we engage with external raw material suppliers or specialized service providers, our vetting is exceptionally rigorous.

The practical steps for comprehensive supplier vetting extend far beyond a simple Google search. It involves systematically verifying credentials, such as ISO 9001 for quality management, specific industry certifications relevant to pipe manufacturing (like API for oil and gas applications or PED for pressure equipment in Europe), and environmental or social compliance certifications if pertinent to your company's values. Financial stability can be assessed through credit reports or financial statements where available. Production capacity and technical capabilities should be confirmed, ideally through factory audits—either in-person or, increasingly, via detailed virtual tours and live-streamed inspections. Requesting and verifying past client testimonials or case studies can also provide invaluable insights into a supplier's reliability and service quality. For instance, when we onboard a new client at MFY, especially one requiring a consistent supply of stainless steel tubes for manufacturing, like an equipment integrator, we often share our own certification portfolio and encourage a (virtual or physical) tour of our facilities to build that foundational trust.

The impact of poor supplier selection is well-documented. According to industry analyses, supply chain disruptions, a significant portion of which can be traced back to issues with supplier reliability or quality, cost businesses billions globally each year. I remember a case involving a manufacturing company in India; they were new to direct international sourcing and chose a supplier based solely on the lowest price for stainless steel pipes. The initial batch arrived with inconsistent wall thickness and poor weld integrity, leading to a high rejection rate and halting their production line for several days while they scrambled for replacements. The few thousand dollars they initially "saved" on the purchase price were dwarfed by the losses from downtime and the cost of expedited replacement material. This scenario highlights why MFY emphasizes a partnership approach; we’re not just selling pipes, we’re providing assurance that stems from our control over the entire production and supply process.

Ambiguity in Specifications and Quality Requirements

Another critical mistake is providing ambiguous, incomplete, or incorrect specifications for the required pipes. The world of stainless steel pipes is governed by a multitude of international and national standards (e.g., ASTM, ASME, EN, DIN, JIS, GOST), various material grades (like 304, 316L, Duplex), precise dimensions (outer diameter, wall thickness, length), specific tolerances, surface finish requirements, and necessary testing protocols (hydrostatic testing, non-destructive testing, mechanical property tests). Failing to clearly and comprehensively define these parameters can lead to the supplier manufacturing or sourcing the wrong product. This not only results in unusable goods but also wastes time and resources on both sides, potentially leading to disputes and project delays. Clear, documented communication of these requirements is paramount.

At MFY, we place immense emphasis on clarifying technical specifications right from the initial inquiry. Our technical sales team works closely with clients, whether they are experienced engineering contractors or distributors, to ensure all parameters are meticulously defined and understood. This often involves detailed discussions, sharing of technical data sheets, and, for custom requirements, collaborative review of drawings. I always tell our clients, like an engineering contractor in Russia we recently supplied for a major industrial project, that precision in the initial specification document is half the battle won. We often encounter situations where a client might specify a common grade like "304 stainless steel pipe" without detailing the specific standard (e.g., ASTM A312 for seamless and welded, or A269 for seamless and welded tubing for general service) or the required schedule/wall thickness. Our team proactively asks these clarifying questions to prevent errors down the line. Pre-production sample approval, especially for large or custom orders, is a standard part of our process to ensure complete alignment before mass production commences.

The confusion can be exacerbated when dealing with different international standards. For example, a client familiar with ASTM standards might need pipes for a project where EN standards are specified. While there are often equivalent grades and specifications, they are not always identical. Differences in chemical composition ranges, mechanical property requirements, or testing procedures can be critical. Below is a simplified comparison of some common stainless steel pipe standards to illustrate potential areas of divergence:

| Feature | ASTM A312 (Typical for US) | EN 10217-7 (Typical for Europe) | JIS G3459 (Typical for Japan) |

|---|---|---|---|

| Primary Scope | Seamless, Welded Austenitic SS Pipes | Welded Austenitic SS Tubes for Pressure Purposes | Stainless Steel Pipes (Austenitic) |

| Common Grades | TP304, TP316, TP321 | 1.4301 (304), 1.4404 (316L) | SUS304TP, SUS316TP |

| Testing Focus | Varies by pipe type/class | Specific to application/condition (e.g., TC1, TC2) | Standardized per grade |

| Dimensional Std. | Often ASME B36.10/B36.19 | EN ISO 1127 | JIS G3459 specifies dimensions |

This table provides a glimpse into why assuming interchangeability without careful verification can be risky. A lack of clarity on such details is a frequent source of error, one that MFY actively works to prevent through diligent technical communication and support.

Neglecting Comprehensive Quality Control and Inspection

Relying solely on the supplier's internal Quality Control (QC) report is a significant gamble that many businesses unfortunately take, often to save on inspection costs. While reputable suppliers will have their own QC processes, an independent verification, whether by your own team or a third-party inspection (TPI) agency, provides an essential layer of assurance, especially when sourcing from a new or distant supplier. This mistake can lead to receiving pipes that don't meet agreed-upon standards, dimensions, material compositions, or performance requirements, resulting in costly rework, rejections, or even catastrophic failures in application. The cost of addressing quality issues after the goods have arrived at your facility is almost always significantly higher than investing in pre-emptive inspection.

A robust quality control plan should ideally encompass several stages. Pre-production inspection can verify raw materials and initial production setups. During-production inspection (DUPRO) allows for corrective actions if deviations are found early in the manufacturing process. Most critically, a Pre-Shipment Inspection (PSI) should be conducted before the goods leave the supplier's facility. This PSI should meticulously check for: material composition (often verified using Positive Material Identification - PMI testing), dimensional accuracy (OD, WT, length), mechanical properties (tensile strength, yield strength, elongation – verified against mill test certificates and potentially re-tested), visual defects (surface finish, weld quality, straightness), correct marking, and proper packaging to prevent damage during transit. At MFY, our integrated supply chain includes stringent QC at every stage, from raw material inspection to final product testing, and we welcome client or third-party inspections.

I recall an instance where we assisted a distributor in the Middle East. They had previously sourced from another supplier and received a large shipment of stainless steel tubes with inconsistent wall thickness. This variation was subtle enough to be missed by a cursory check but critical for their customers' applications. A diligent DUPRO or a comprehensive PSI focusing on dimensional checks across a statistical sample would have caught this issue early, saving them considerable financial loss and reputational damage. The cost of poor quality (COPQ) isn't just the value of the defective goods; it includes sorting costs, potential rework, production delays for their customers, and loss of goodwill. Industry estimates often place COPQ as high as 15-20% of sales revenue in some manufacturing sectors, underscoring the economic sense of investing in thorough quality control. This proactive approach to quality assurance is a cornerstone of MFY’s commitment to our clients.

Supplier vetting prevents costly errorsTrue

Thorough supplier due diligence helps avoid issues like substandard materials and unreliable deliveries that can derail projects.

Price should be the sole supplier criterionFalse

Choosing suppliers based only on price often leads to quality issues and hidden costs that outweigh initial savings.

Why do these mistakes occur in international pipe sourcing?

Wondering why these international sourcing errors keep happening despite the best intentions and available information? The reality is that the global sourcing landscape is inherently complex. The root causes are often multifaceted, involving vast geographical distances that hinder direct oversight, subtle but impactful cultural nuances in communication and business practices, and a persistent information asymmetry between buyers and sellers, all of which can lead to significant frustration and costly missteps.

These mistakes often occur due to a lack of international sourcing experience, intense pressure to cut costs hastily, persistent communication barriers (language and cultural), inadequate market research into suppliers and local conditions, and sometimes an over-reliance on intermediaries without performing independent checks.

Understanding these underlying reasons is the crucial first step towards building a more resilient and effective international pipe sourcing process. It's not always about negligence; sometimes, it's about being unaware of the potential pitfalls or lacking the resources and expertise to navigate them effectively. For instance, a procurement manager under immense pressure to reduce costs might feel compelled to select the supplier with the absolute lowest bid, potentially overlooking warning signs during a rushed vetting process. Similarly, a company new to sourcing from a specific region might underestimate the impact of local holidays3 on production lead times or the intricacies of local customs clearance procedures.

From my vantage point at MFY, I've seen how easily these factors can combine to create problems. For example, a European equipment integrator, pressed for both time and budget on a new project, might expedite their supplier selection process for stainless steel components. They might rely heavily on online profiles and initial price quotes, perhaps forgoing a deeper dive into supplier audits or detailed contractual negotiations regarding quality assurance and dispute resolution. This isn't due to a lack of professionalism, but rather the convergence of operational pressures. The allure of a quick, cheap solution can be strong, but as we often see, the true cost emerges later in the form of delays, defects, or contractual disputes. Our role at MFY is not just to supply high-quality stainless steel pipes, but also to help our clients navigate these complexities by leveraging our experience and transparent processes, thereby mitigating the risks associated with these common underlying causes of sourcing mistakes.

The recurrence of mistakes in international pipe sourcing isn't arbitrary; it's often rooted in systemic challenges inherent in cross-border trade. These challenges are amplified when dealing with industrial products like pipes, where technical specifications are critical and the consequences of failure can be severe. Understanding the "why" behind these errors allows businesses to develop more targeted and effective preventative strategies. It’s about recognizing that the lowest price on paper doesn't always translate to the best value, especially when hidden risks and potential long-term costs are factored in. At MFY, our deep involvement in China's stainless steel ecosystem, combined with our global outlook, provides us with a unique perspective on these issues. We've learned that proactive communication, cultural sensitivity, a meticulous approach to detail, and a commitment to understanding the client's total needs are paramount in overcoming these hurdles. This insight allows us to guide our clients, from manufacturing companies to engineering contractors, towards more predictable and successful sourcing outcomes.

Communication Gaps and Cultural Misunderstandings

One of the primary reasons mistakes occur is due to communication gaps and cultural misunderstandings. While language barriers are the most obvious aspect – a mistranslated technical term or a nuance lost in translation can have significant consequences for pipe specifications – the more subtle challenges often lie in differing communication styles and business_etiquette. For instance, in some cultures, a direct "no" or open disagreement is considered impolite, leading to indirect communication that can be misinterpreted by buyers accustomed to more straightforward exchanges. This can result in a supplier seeming to agree to terms or timelines they cannot realistically meet, simply to avoid confrontation or maintain harmony.

At MFY, with our extensive experience dealing with clients from India, Southeast Asia, the Middle East, Russia, and beyond, we invest heavily in our communication infrastructure. Our teams are proficient in multiple languages, but more importantly, they are trained in cross-cultural communication. We understand, for example, the importance of "guanxi" (relationships and networking) in Chinese business culture and how it influences negotiations and long-term partnerships. We strive to be clear, direct, and transparent in our dealings, while also being sensitive to our clients' cultural backgrounds. I recall a negotiation with a new client from a Western country who was frustrated by what they perceived as evasiveness from a potential local sub-supplier (not MFY). We were able to mediate, explaining that the supplier's indirectness was likely an attempt to show respect and avoid outrightly saying they couldn't meet a very aggressive price target, rather than an attempt to deceive. Facilitating this understanding helped bridge the gap.

Time zone differences also contribute to communication challenges, making real-time collaboration and urgent problem-solving more difficult. A quick query from a buyer in Europe might only get a response the next day from a supplier in Asia, potentially delaying decisions or clarifications. The Project Management Institute (PMI) has consistently highlighted in its "Pulse of the Profession" reports that ineffective communication is a primary contributor to project failure, with some studies indicating it plays a role in over half of all unsuccessful global projects. This underscores the need for clear communication protocols, regular updates, and leveraging technology like video conferencing and shared project management platforms to keep all parties aligned, a practice we actively encourage at MFY.

Pressure for Cost Reduction vs. Total Cost of Ownership (TCO)

The intense and often relentless pressure to reduce procurement costs is another major driver of sourcing mistakes. While managing budgets is crucial, an exclusive focus on the initial purchase price of pipes, without considering the Total Cost of Ownership (TCO), can be a shortsighted strategy. TCO encompasses not only the unit price but also a host of other direct and indirect costs, such as shipping and logistics, import duties and taxes, insurance, financing costs, quality inspection fees, the cost of potential defects or rework, inventory holding costs, and even the administrative overhead of managing an international supplier. Opting for the cheapest supplier might lead to inferior quality pipes that fail prematurely, require frequent replacement, or cause damage to other equipment, ultimately resulting in much higher costs in the long run.

At MFY, we encourage our clients, especially manufacturing companies looking for reliable, long-term supply solutions, to adopt a TCO perspective. We work with them to understand how our high-quality stainless steel pipes, manufactured under stringent controls within our integrated supply chain, can contribute to lower overall costs, even if the initial unit price isn't the absolute rock bottom in the market. For example, we helped a client in Russia, a large industrial equipment manufacturer, analyze their TCO. They were initially tempted by a significantly cheaper offer from a small, unknown trader. However, after factoring in the higher risk of quality issues, potential for delivery delays (based on the trader's lack of track record), and the more stringent inspection protocols they would need to implement, they realized that partnering with MFY, a reputable manufacturer with proven reliability and transparent processes, offered better long-term value and lower overall risk. Our rapid export delivery and strong inventory also mean reduced lead times and less need for them to hold excessive safety stock.

Hidden costs can significantly inflate the perceived savings from a low bid. Currency fluctuations can erode expected margins if not hedged properly. Unfavorable payment terms might strain cash flow. The cost of delays due to a supplier's inefficiency can have a ripple effect on project timelines and contractual penalties. Warranty claims can be difficult and costly to pursue with distant or unresponsive suppliers. According to a report by The Hackett Group, companies that focus predominantly on purchase price variance without a holistic view of TCO can experience overall costs that are up to 20% higher than those with a more strategic sourcing approach. This highlights the importance of looking beyond the sticker price to the true, comprehensive cost.

Lack of Local Market Knowledge and Regulatory Awareness

A significant number of mistakes stem from a sheer lack of local market knowledge and an underestimation of the complexities of regulatory environments in the supplier's country. Each nation has its own unique set of import/export regulations, customs procedures, product standards, certification requirements, tax laws, and business practices. Ignorance or misunderstanding of these local nuances can lead to a host of problems, including consignments being held up at customs, unexpected tariffs or fines, delays in clearance, or even the rejection of goods if they don't meet specific local standards that weren't anticipated. For instance, certain countries may require specific fumigation certificates for wooden packaging, or particular product testing and certifications (like BIS in India for certain steel products) before goods can be imported.

As a China-based company with extensive export experience to markets like India, Southeast Asia, the Middle East, and Russia, MFY has developed a deep understanding of the regulatory landscapes in these regions. We navigate China's export procedures daily and keep abreast of the import requirements of our key markets. This expertise is a crucial part of the value we offer. For example, we recently guided a new distributor client in India through the complexities of BIS certification for a specific range of stainless steel pipes they intended to stock. Without this guidance, they might have faced significant delays and costs trying to import non-certified goods. Our team ensures that all documentation, from commercial invoices and packing lists to certificates of origin and mill test certificates, is accurate and compliant with the requirements of both China and the destination country.

The international trade environment is also dynamic, with policies, tariffs, anti-dumping duties, and sanctions subject to change, sometimes with little notice. This volatility underscores the importance of working with a partner who is not only knowledgeable but also agile and proactive in monitoring these shifts. For instance, recent changes in trade agreements or the imposition of new environmental regulations in a specific export market can impact documentation, cost, and lead times. At MFY, our market intelligence teams actively track such developments to advise our clients and adjust our processes accordingly. We recently helped several clients shipping to various Southeast Asian countries navigate new customs declaration requirements, ensuring their shipments proceeded smoothly without unexpected hold-ups, saving them considerable time and potential penalties. This local market and regulatory awareness is a critical component of successful international sourcing.

Cultural differences impact sourcingTrue

Cultural nuances in communication styles and business etiquette can lead to misunderstandings in international pipe sourcing.

Lowest price always means best valueFalse

The initial purchase price doesn't account for Total Cost of Ownership (TCO), which includes hidden costs like quality issues and delays.

How can mistakes in international pipe sourcing negatively impact businesses?

Thinking that sourcing slip-ups are just minor operational hiccups is a dangerous misconception; in reality, they can send damaging shockwaves through your entire business operation. From crippling project delays that infuriate your clients and trigger penalty clauses, to severe budget overruns that erode profitability, and ultimately, to a tarnished reputation that can take years to rebuild, the fallout from these mistakes is often far-reaching and severe.

Mistakes in international pipe sourcing can lead to severe financial losses from increased costs and lost sales, significant operational disruptions such as project delays and production stoppages, lasting reputational damage, potential legal liabilities, and severely strained supplier and customer relationships.

It's crucial to understand that the negative impacts are not confined to the procurement department. A shipment of substandard pipes, for example, doesn't just represent a financial loss on that specific order; it can halt a manufacturing production line, delay a critical construction project, or, worse, lead to a product failure in the field. I've seen firsthand at MFY how a single, seemingly small sourcing error made by a company before they came to us, can snowball into a cascade of problems. Consider an engineering contractor working on a critical public infrastructure project, like a water treatment plant. If the stainless steel pipes they sourced internationally arrive late, or fail quality inspection, the entire project timeline can be jeopardized. This not only incurs direct costs for the contractor but can also impact the community relying on that infrastructure.

MFY’s proactive approach, including our fully integrated supply chain and rigorous quality control, is designed to systematically mitigate these risks for our clients. We understand that the reliability of the components we supply, such as stainless steel pipes and tubes, is fundamental to our clients' success. Therefore, appreciating the full spectrum of potential negative impacts underscores the strategic importance of diligent and intelligent international sourcing. It’s an investment in your business's stability, profitability, and reputation. The consequences of getting it wrong are simply too high to leave to chance.

The repercussions of errors in international pipe sourcing extend far beyond mere inconvenience; they can fundamentally undermine a business's operational stability, financial health, and market standing. These are not just theoretical risks but tangible threats that materialize when diligence is compromised. For a manufacturing company, a faulty batch of pipes can mean production halts and an inability to meet customer orders. For an engineering or construction contractor, it can lead to project overruns, contractual penalties, and safety hazards. For distributors and traders, unreliable supply or poor quality erodes customer trust and market share. At MFY, we have built our reputation on reliability and quality precisely because we understand these profound impacts on our clients' businesses. Our commitment to excellence in every stainless steel pipe and tube we produce and export is a direct response to the need for certainty and dependability in a complex global supply chain. Exploring these negative impacts in detail will reinforce why a meticulous, informed approach to international sourcing isn't just best practice—it's a business imperative.

Severe Financial Repercussions

The most immediate and easily quantifiable impact of sourcing mistakes is financial. Direct costs can accumulate rapidly: paying for defective or non-compliant pipes that must be scrapped, incurring costs for rework or modification if feasible, paying for expedited shipping for replacement materials to meet urgent deadlines, and facing contractual penalties for project delays caused by sourcing issues. If substandard pipes are unknowingly incorporated into a larger assembly or project, the cost of recall, repair, or replacement can be astronomical, far exceeding the initial cost of the pipes themselves. These direct financial hits can significantly erode project profitability and strain company budgets.

Beyond these direct expenses, the indirect financial costs can be even more substantial, though sometimes harder to attribute immediately. Lost production time due to a lack of necessary materials or because of equipment damage caused by faulty pipes directly translates into lost revenue. Missed sales opportunities because products cannot be manufactured or delivered on time can have long-term consequences on market share. I recall a conversation with a manufacturing client who, before partnering with MFY, experienced a critical failure in their processing equipment. The cause was traced back to improperly treated stainless steel tubes4 sourced from a previous supplier, which led to premature corrosion. The unscheduled downtime and emergency repairs cost them significantly more than the entire initial pipe order, not to mention the stress and disruption to their operations.

Furthermore, the broader economic impact can be severe. The Chartered Institute of Procurement & Supply (CIPS) has published data suggesting that significant supply chain disruptions can reduce a company's share price by an average of 7-10%, a stark indicator of how the financial markets react to sourcing vulnerabilities. For businesses dealing with products where safety is critical, a product recall necessitated by faulty components, such as pipes failing under pressure, can lead to multi-million dollar expenses, covering not just the logistics of the recall but also legal fees, regulatory fines, and brand damage control. This is why MFY’s commitment to providing fully certified and tested stainless steel pipes is unwavering; we understand the immense financial responsibilities our clients carry.

Operational Disruptions and Project Delays

Mistakes in international pipe sourcing are a direct route to significant operational disruptions and costly project delays. When a shipment of pipes is late, incorrect, or fails quality inspection upon arrival, it can bring manufacturing lines to a standstill or halt progress on construction sites. These delays are rarely isolated; they often have a cascading effect on subsequent activities and other contractors or departments that depend on the timely completion of earlier stages. For instance, if specialized stainless steel pipes for a chemical processing plant are delayed, the installation of other critical equipment, electrical work, and commissioning can all be pushed back, leading to a domino effect of delays across the entire project schedule.

Consider a large-scale construction project, perhaps an LNG terminal or a power plant, common in regions like the Middle East where MFY supplies materials. These projects operate on tight schedules with multiple contractors working in parallel. The timely delivery of specified piping systems is absolutely critical. A delay of even a few weeks, perhaps due to a supplier misinterpreting specifications or facing unexpected production issues they failed to communicate, can lead to substantial liquidated damages for the main contractor. MFY’s strength in rapid export delivery and maintaining a robust inventory of common stainless steel pipe grades and sizes is a key factor in helping our clients, including engineering and construction contractors, avoid such disruptive delays. We understand that for them, time is money, and reliability is paramount.

These disruptions also wreak havoc on inventory management. Companies might be forced to hold excessive safety stock to buffer against unreliable international suppliers, tying up working capital and incurring storage costs. Conversely, unexpected delays can lead to stockouts of critical pipe components, leading to lost sales for distributors or production stoppages for manufacturers. At MFY, our strong production capacity and sophisticated inventory management systems are designed to provide a reliable buffer and ensure a consistent supply of stainless steel pipes. This predictability is particularly valued by our distributor clients who need to maintain adequate stock levels to service their own customers effectively, and by manufacturing companies that rely on just-in-time principles.

Reputational Damage and Loss of Customer Trust

Perhaps one of the most insidious and long-lasting impacts of sourcing mistakes is the damage to a company's reputation and the erosion of customer trust. If a business delivers a final product or completes a project that subsequently fails or underperforms due to substandard components like faulty pipes, the reputational fallout can be severe. In today's interconnected world, news of poor quality or unreliability can spread quickly through social media, industry forums, and customer reviews, making it incredibly difficult to control the narrative. This is particularly critical for businesses like equipment integrators, where the reliability of every single component, including the stainless steel tubes and pipes sourced from MFY, reflects directly on their overall product quality and brand promise.

Once customer trust is lost, it is exceptionally difficult and costly to regain. A single instance of supplying a defective product can lead to lost repeat business, and negative word-of-mouth can deter potential new customers. For businesses in competitive markets, reputation is a key differentiator. If clients perceive a company as unreliable due to issues stemming from its supply chain, they are likely to turn to competitors who can offer greater assurance of quality and timely delivery. At MFY, we are acutely aware that when we supply pipes to a manufacturer, their end-product's reputation is partly in our hands. This shared responsibility drives our stringent quality protocols.

There are numerous high-profile cases in various industries where a product recall, necessitated by a faulty sourced component, has led to a significant and lasting decline in brand perception and market share. The cost of such an event goes far beyond the immediate financial expenses of the recall itself; it encompasses marketing efforts to rebuild trust, potential loss of key accounts, and a diminished ability to command premium pricing. This underscores why MFY’s vision to become a leading international trade and service brand in China’s stainless steel industry is built on a foundation of uncompromised quality and reliability. We understand that the stainless steel pipes we supply are often critical components in our clients' value chains, and their success and reputation depend on our performance.

Sourcing errors can halt production linesTrue

Defective or delayed pipe shipments can directly stop manufacturing processes, as explained in the infrastructure project example.

Financial impacts are only direct costsFalse

The article highlights both direct costs (rework, penalties) and substantial indirect costs like lost market share and stock price declines.

What solutions exist to avoid making mistakes in international pipe sourcing?

Tired of navigating the treacherous waters of the international pipe sourcing maze, constantly fearing those costly and disruptive errors? These recurring mistakes can indeed lead to significant financial setbacks, operational bottlenecks, and an immense amount of stress for procurement teams and project managers alike. Fortunately, a range of effective solutions and well-defined strategies exist to streamline your process, mitigate risks, and ensure consistently successful outcomes.

Solutions to avoid international pipe sourcing mistakes include implementing thorough supplier qualification processes, drafting crystal-clear contractual agreements with detailed specifications, establishing robust quality assurance and inspection plans, fostering effective and transparent communication protocols, and strategically partnering with experienced sourcing agents or reputable direct manufacturers.

At MFY, we've essentially built our entire business model around providing these very solutions to our clients. For us, it’s not just about selling stainless steel pipes and tubes; it’s about delivering a comprehensive service package that ensures peace of mind and tangible value. Our integrated supply chain, from raw material sourcing through production to export logistics, embodies many of these solutions inherently. When a new client, perhaps a manufacturing firm that has previously struggled with unreliable overseas suppliers, approaches MFY, we don't just offer them a product list. We walk them through our structured approach: how we ensure quality at every stage, how we manage specifications to avoid ambiguity, how our logistics ensure timely delivery, and how our team provides ongoing support.

For instance, a manufacturing company in India recently partnered with us. They had faced issues with inconsistent material grades from previous suppliers, impacting their product's performance. We implemented a solution involving joint specification reviews, pre-production sample approvals, and provided them with full traceability and comprehensive Mill Test Certificates (MTCs)5 for every batch of stainless steel tubes. This level of transparency and control, which is a solution to the common problem of quality ambiguity, gave them the confidence they needed. Moving from identifying problems to actively implementing solutions is key, and that's where experienced partners can make a significant difference.

The journey from recognizing potential pitfalls to establishing a consistently successful international pipe sourcing strategy is paved with proactive measures and strategic choices. It’s about building a framework that anticipates challenges and incorporates safeguards at every critical juncture. These solutions aren't just theoretical constructs; they are actionable steps that can transform your procurement function from a reactive cost center into a strategic value driver. At MFY, our commitment to being more than just a supplier is rooted in our understanding that our clients – be they large engineering contractors, agile manufacturing companies, or dynamic distributors – need reliable partners who can help them navigate the complexities of global sourcing. Our integrated model, from controlling raw material inputs for our stainless steel pipes to managing the intricacies of export to diverse markets like Southeast Asia, the Middle East, and Russia6, is designed to be a comprehensive solution in itself. By exploring these solutions in depth, businesses can equip themselves with the knowledge to build resilient, efficient, and cost-effective international supply chains.

Implementing a Rigorous Supplier Qualification Process

A cornerstone solution to avoiding sourcing mistakes is the implementation of a truly rigorous supplier qualification process. This goes far beyond simply collecting a few price quotes. It involves a multi-faceted evaluation of potential suppliers, assessing not just their commercial offers but also their technical capabilities, financial stability, adherence to quality management systems (evidenced by certifications like ISO 9001, and product-specific certifications such as API Q1 for oil and gas or PED/AD2000 for pressure vessels in Europe7), and their track record for reliability and ethical sourcing practices. This detailed scrutiny helps filter out unqualified or risky suppliers before any significant commitments are made.

The practical execution of such a process includes several key steps. Factory audits and site visits (which can be conducted virtually with increasing effectiveness using modern technology) are invaluable for assessing a supplier's production facilities, equipment, internal QC processes, and overall operational professionalism. "When MFY onboards a new strategic partner for specialized raw materials or unique processing capabilities that complement our own stainless steel pipe manufacturing, our internal audit team conducts a thorough assessment. This same level of rigor is what we advocate for our clients when they are evaluating any supplier," I often explain. We believe that understanding a supplier's operational depth is critical. This process should also include verifying references and checking for any history of disputes or poor performance.

Developing a weighted scorecard for supplier selection can also bring objectivity to the decision-making process, allowing businesses to rank potential suppliers based on a range of criteria (e.g., quality, price, lead time, technical support, financial health) that are weighted according to their strategic importance. Industry research consistently shows the benefits of such mature approaches. For instance, studies by CAPS Research indicate that companies with well-developed supplier relationship management (SRM) programs, which naturally begin with robust qualification, report significantly lower procurement costs and notable improvements in supplier performance and innovation. This structured approach helps ensure that decisions are based on a comprehensive assessment of value and risk, not just on the initial price tag.

Establishing Crystal-Clear Specifications and Contracts

Another fundamental solution lies in establishing crystal-clear product specifications and comprehensive contractual agreements. Ambiguity is the enemy of successful sourcing. Therefore, detailed technical specification sheets are non-negotiable. These must clearly define all critical parameters for the stainless steel pipes: the exact international standard(s) to be met (e.g., ASTM A312, EN 10217-7), specific material grades (e.g., 316L, S32205 Duplex), precise dimensional requirements (outer diameter, wall thickness, length) along with acceptable tolerances, surface finish requirements, end preparation (e.g., plain end, beveled end), marking instructions, and all necessary testing and inspection criteria. Leaving any of these open to interpretation is an invitation for error.

Contractual safeguards are equally vital. The formal agreement should meticulously outline all terms and conditions, including unambiguous clauses on quality standards and acceptance criteria, firm delivery schedules (specifying Incoterms like FOB, CIF, DDP to clarify responsibilities and cost allocation), payment terms and currency, comprehensive warranty provisions, clear mechanisms for dispute resolution (e.g., arbitration clauses and governing law), and, where applicable, clauses protecting intellectual property. "I always advise our clients, especially those engaging in high-value or long-term contracts for stainless steel pipes, to have their legal counsel review international agreements," I share. "At MFY, our standard sales contracts are carefully drafted to be comprehensive and balanced, reflecting our extensive experience in international trade and aiming to prevent misunderstandings before they arise."

The role of Pre-Production Samples (PPS) and, for very complex or high-volume orders, pilot production runs, cannot be overstated as part of this solution. Requesting and approving a PPS ensures that both the buyer and the supplier have an identical understanding of the final product's requirements before mass production begins. This step can save enormous amounts of time and money by catching any discrepancies or misinterpretations early. For a particularly intricate order of custom-fabricated stainless steel tubular components for an equipment integrator in the automotive sector, MFY went through several iterations of PPS approval, including fitment trials on their end. This collaborative process ensured that the final production run met their exacting needs perfectly, preventing costly rework and delays.

Leveraging Expert Partnerships and Local Knowledge

For many businesses, particularly those that are new to international sourcing or lack dedicated in-house expertise for specific regions or commodities, leveraging expert partnerships is a highly effective solution. This can take the form of working with reputable and well-established direct manufacturers who have significant export experience, like MFY, or engaging specialized sourcing agents or consultants who possess deep on-the-ground presence and local market understanding in the target sourcing country. Such partners can help navigate the complexities of a foreign business environment, identify reliable suppliers, manage quality control, and handle logistics and regulatory hurdles.

At MFY, we position ourselves as more than just a manufacturer and supplier of stainless steel pipes; we aim to be a strategic partner for our clients. "Our clients, particularly those sourcing from China for the first time or those looking to consolidate their supplier base, benefit immensely from our deep understanding of the local manufacturing landscape, our established logistics network, and our up-to-date knowledge of the regulatory environment," I often emphasize. "We effectively become an extension of their procurement team, providing insights and services that go far beyond a simple transactional relationship." This is a core component of MFY’s "one-stop solution" philosophy, designed to simplify the sourcing process and mitigate risks for our clients, whether they are large manufacturing companies or specialized engineering contractors.

The value of an integrated supply chain, like the one MFY operates, represents a powerful intrinsic solution. By controlling multiple stages of the process—from sourcing quality raw materials and precision cold-rolling (if applicable for certain tube types) to state-of-the-art pipe manufacturing, rigorous quality testing, and efficient export logistics—we can offer greater assurance of quality, more reliable lead times, and enhanced traceability. This vertical integration inherently reduces many of the common risks associated with sourcing from fragmented or less transparent supply chains. For example, when a distributor in India needs a mix of standard and custom-sized stainless steel pipes with specific testing requirements, MFY’s ability to manage this entire process in-house, ensuring compliance with Indian import regulations and BIS standards where applicable, provides a seamless and reliable solution that they might struggle to achieve by coordinating multiple independent entities.

Supplier qualification prevents mistakesTrue

A rigorous supplier qualification process evaluates technical capabilities and financial stability to filter out risky suppliers before commitments are made.

Price is the only supplier criterionFalse

Supplier selection should consider multiple factors like quality, lead time, and technical support, not just price, as shown in weighted scorecard approaches.

What best practices can be followed for successful international pipe sourcing?

Ready to transform your international pipe sourcing from a potential gamble into a consistent strategic advantage for your business? Without a defined and consistently applied set of best practices, you risk falling into common traps of inefficiency, unexpected costs, and quality issues, ultimately hindering your company's growth and competitiveness. Adopting these proven strategies will pave the way for more predictable, reliable, and successful procurement outcomes in the global marketplace.

Best practices for successful international pipe sourcing include cultivating long-term collaborative supplier relationships, conducting continuous market research and due diligence, embracing technology for enhanced communication and tracking, implementing comprehensive risk management strategies, and consistently focusing on total value and TCO over just the initial price.

These aren't just abstract theoretical concepts; at MFY, these best practices are deeply embedded into our daily operations and our overarching business philosophy. They are reflected in how we interact with our clients, how we manage our production of stainless steel pipes, and how we innovate within our supply chain. Our core values of agility, resilience, and continuous evolution naturally align with these principles. For example, our commitment to continuous evolution drives us to constantly research market trends and adopt new technologies to improve efficiency and transparency for our clients sourcing stainless steel tubes and pipes.

Think of these best practices as the robust pillars supporting a strong, reliable, and cost-effective international supply chain for your critical stainless steel pipe needs. I've seen many clients, from large engineering contractors to specialized manufacturing companies, achieve significant improvements in their sourcing outcomes by systematically adopting such practices, often in collaboration with MFY. One such client, a manufacturer of food processing equipment, initially focused heavily on price. By working with us to implement best practices like detailed joint specification reviews, a long-term supply agreement fostering collaboration, and leveraging our quality assurance systems, they not only ensured consistent quality for their stainless steel tubing but also reduced their overall TCO through fewer rejects and more reliable deliveries.

Achieving sustained success in international pipe sourcing requires a proactive, strategic, and continuously improving approach. It's about moving beyond purely transactional relationships and reactive problem-solving to build a resilient and efficient global supply network. The best practices outlined below are not merely suggestions but foundational elements that distinguish leading procurement organizations. At MFY, our vision to become the leading international trade and service brand in China’s stainless steel industry is intrinsically linked to our adherence to these principles. We believe that by helping our clients implement these best practices for their stainless steel pipe and tube requirements, we contribute directly to their competitive advantage. Whether you are a distributor aiming for reliable stock, an engineering contractor needing project-specific solutions, or a manufacturer requiring consistent component quality, these strategies will provide a roadmap to excellence8 in global sourcing.

Cultivating Long-Term, Collaborative Supplier Relationships

A fundamental best practice is to move beyond short-term, transactional interactions with suppliers and instead focus on cultivating long-term, collaborative relationships. Viewing your key pipe suppliers as strategic partners rather than just vendors can yield significant benefits. These include improved communication and understanding, greater willingness from the supplier to be flexible and accommodate specific needs, preferential treatment during periods of high demand or material shortages, a collaborative approach to problem-solving and innovation, and ultimately, enhanced reliability and trust. Such relationships are built on mutual respect, transparency, and a shared commitment to quality and continuous improvement.

At MFY, we actively seek to build these kinds of enduring partnerships with our clients. "We see our key clients, such as a major distributor of stainless steel pipes in Southeast Asia with whom we've had a successful trading relationship for over a decade, as true partners in our growth," I often share. "This long-term perspective allows us to deeply understand their evolving market needs, anticipate their requirements, and proactively manage their supply chain for stainless steel products. It leads to a much more efficient and less adversarial dynamic than constantly re-tendering for every order." This approach often involves regular review meetings, open sharing of forecasts, and joint efforts to optimize logistics or product specifications for better cost-effectiveness.

Engaging in joint business planning and conducting periodic performance reviews with key suppliers are practical ways to foster this collaboration. This allows both parties to align on strategic goals, identify areas for improvement, and track progress against key performance indicators (KPIs) such as on-time delivery, quality acceptance rates, and cost-saving initiatives. Industry research, for example by McKinsey & Company, has shown that companies excelling in supplier collaboration tend to achieve higher growth, greater profitability, and more innovation. This is particularly true in volatile commodity markets like stainless steel, where a trusted relationship with a reliable manufacturer like MFY can provide a significant competitive edge by ensuring supply stability and predictable pricing structures where possible.

Embracing Technology and Data-Driven Decision Making

In today's fast-paced global economy, embracing technology is no longer optional but a critical best practice for efficient and effective international pipe sourcing. Digital tools can significantly enhance various aspects of the procurement process, from initial supplier discovery and qualification (using online databases and B2B platforms) to ongoing communication (via video conferencing, instant messaging, and shared project management software), real-time order tracking and visibility, and streamlined management of quality control documentation and certifications. MFY’s ongoing investment in digital innovation is a testament to our belief in technology's power to transform the supply chain.

Leveraging data analytics is another key component of this best practice. By systematically collecting and analyzing procurement data, businesses can gain valuable insights for market trend analysis (e.g., tracking stainless steel price fluctuations), monitoring supplier performance against agreed KPIs, improving demand forecasting accuracy, and identifying opportunities for cost optimization or risk mitigation. "At MFY, our internal software development team works on creating bespoke tools that help us better manage our integrated supply chain, from raw material inventory to production scheduling for stainless steel pipes, and importantly, provide our clients with enhanced real-time visibility into their orders," I explain to clients. This transparency builds trust and allows for more proactive decision-making on their end.

The effective use of Enterprise Resource Planning (ERP) systems is also crucial for integrating procurement activities with other core business functions such as inventory management, production planning, and finance. This integration ensures data consistency, improves process efficiency, and provides a holistic view of the supply chain. Technology proved its worth during recent global disruptions, where companies with more digitized and transparent supply chains were generally better able to adapt and respond to challenges. Our clients, whether they are large manufacturing companies or specialized equipment integrators, consistently tell us they appreciate the visibility and efficiency that MFY’s technology-enabled processes provide. For instance, an engineering contractor working on a time-sensitive project can track their specific order of stainless steel tubes from our production floor to the port of loading, all through a secure client portal we are developing.

Proactive Risk Management and Contingency Planning

A third vital best practice is the implementation of proactive risk management and robust contingency planning. International sourcing is inherently exposed to a wide array of potential risks, including geopolitical instability affecting supplier regions, logistical disruptions (port congestion, shipping delays, carrier capacity issues), quality failures, supplier financial distress or bankruptcy, currency fluctuations, and changes in trade policies or regulations. Ignoring these risks is a recipe for disaster; proactively identifying, assessing, and mitigating them is essential for building a resilient supply chain for critical items like stainless steel pipes.

Developing effective mitigation strategies involves several approaches. Diversifying the supplier base for critical components can reduce over-reliance on a single source, although for a highly integrated and reliable partner like MFY, we aim to be the dependable primary source that negates much of this need for our specific product lines. Building in appropriate buffer stock for essential pipes, especially those with long lead times or subject to volatile supply, can help cushion against unexpected disruptions. Having pre-qualified alternative shipping routes or logistics providers can provide flexibility if primary channels are compromised. "While MFY prides itself on being a fully integrated and highly reliable global supplier of stainless steel pipes," I often tell clients, "we also understand the broader context of supply chain risk. For an extremely critical project with non-negotiable deadlines, we might work with the client to pre-book shipping capacity well in advance, or even explore options like partial air freight for a small but vital portion of the order if sea freight routes face unforeseen global congestion."

Supply chain mapping is an increasingly important tool in this context, helping businesses to visualize and understand their end-to-end supply network, identify critical dependencies, and pinpoint potential vulnerabilities often hidden in lower tiers of the supply chain. A recent survey by the Business Continuity Institute (BCI) starkly revealed that a high percentage of organizations (often cited over 60-70%) still lack full visibility into their extended supply chains. Recognizing this common blind spot, MFY strives to offer maximum transparency for the stainless steel pipe segment of our clients' operations. Ultimately, developing a robust "Plan B" (and sometimes even a "Plan C") for critical supplies is not a sign of pessimism, but a hallmark of sound strategic planning and a commitment to ensuring business continuity.

Long-term supplier relationships improve reliabilityTrue

Building collaborative partnerships with suppliers leads to better communication, flexibility, and preferential treatment during shortages.

Price should be the sole focus in pipe sourcingFalse

Total cost of ownership (TCO) including quality, reliability and service is more important than just initial price.

Conclusion

Avoiding international pipe sourcing mistakes requires diligent supplier vetting, crystal-clear communication, and robust quality control. Proactive risk management, fostering strategic partnerships, and focusing on total value over mere price are paramount for successful global procurement and building a resilient, competitive stainless steel supply chain.

-

Learn about studies on supply chain disruptions from sourcing errors affecting profitability ↩

-

Gain insights on strategies to avoid sourcing errors and ensure project success internationally ↩

-

Understand how regional holidays can impact production timelines and delivery schedules. ↩

-

Understand the technical aspects and prevention of corrosion caused by faulty sourcing ↩

-

Gain insights into the comprehensive details provided in MTCs. ↩

-

Learn about stainless steel pipe demand in these regions. ↩

-

Understand certification importance for oil, gas, and pressure vessels. ↩

-

Discover key strategies that improve reliability and efficiency in global sourcing ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.